System and method for automatic reporting of chemical composition between steel quality and sap system

A chemical composition and quality system technology, applied in special data processing applications, instruments, electrical digital data processing, etc., can solve the problems of lack of system coherence, lack of quality data verification mechanism, and inability to save data reporting records. The effect of the speed of circulation and improving the efficiency of information flow transmission

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be further described below in conjunction with accompanying drawings and examples.

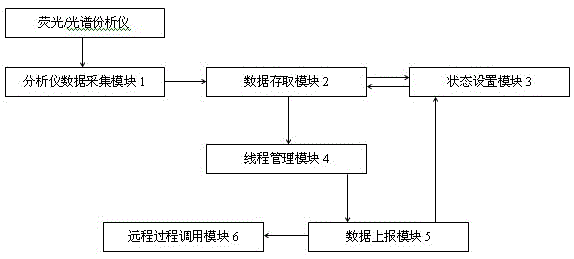

[0017] The present invention is a system that is applied to the automatic reporting of chemical composition results between the iron and steel enterprise quality system and the SAP system. Module 4, data reporting module 5, remote procedure call module 6 in the SAP system, such as figure 1 As shown, the steel quality system is connected with the fluorescence / spectral analyzer installed in the laboratory through a serial port to transmit data.

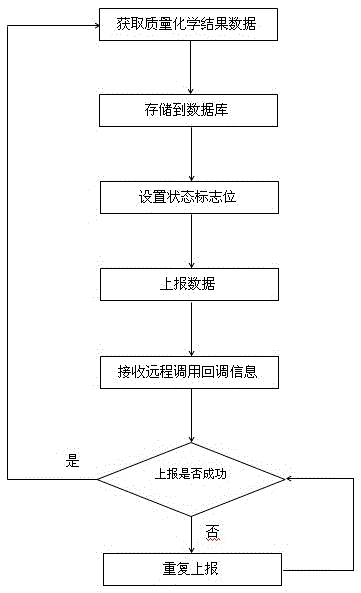

[0018] The analyzer data acquisition module 1 in the iron and steel quality system acquires chemical composition analysis data from the fluorescence / spectral analyzer, and submits the acquired data to the data storage module 2 for storage. The storage medium is a database, and at the same time, the status setting module 3 is called to set the data The state of the state is not reported state, and thread management modu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com