Reclosing mechanism and method of leakage circuit breaker with clutch mechanism

A technology of leakage circuit breaker and clutch mechanism, applied in the direction of protection switch operation/release mechanism, etc., can solve problems such as increased production cost, influence of circuit breaker use, and difficulty in gear processing, and achieves the effect of reliable operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

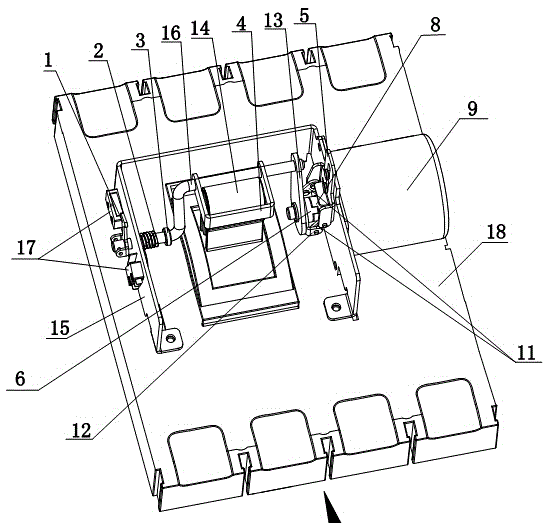

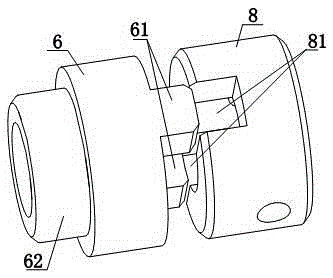

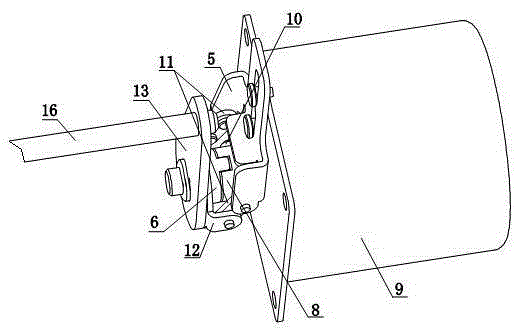

[0027] see Figure 1-3 As shown, the leakage circuit breaker itself has an outer cover 18 and a handle 14, the handle 14 is located in the middle of the circuit breaker outer cover 18 and the handle 14 protrudes upwards outside the circuit breaker outer cover 18, the handle 14 can be towards the circuit breaker inlet terminal or The direction of the outlet end is rotated, such as figure 1 The rear end in the middle is the incoming line end, and the front end is the outgoing line end. The present invention includes outer frame 15, connecting rod, rotating disk, driving lever, handle driver etc., outer frame 15 is fixedly installed on the outer cover 18, handle 14 is positioned between the left side wall of outer frame 15 and the right side wall during installation. A driving rod 16 is rotatably connected between the left side wall and the right side wall of the outer frame 15, the left end of the driving rod 16 is rotatably connected to the left side wall of the outer frame 15...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com