Automatic zero-clearance by-pass connection system for storage battery pack

A technology for battery packs and storage batteries, which is used in secondary batteries, secondary battery repair/maintenance, circuits, etc., and can solve problems such as insecurity, high maintenance costs, and inaccurate monitoring.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

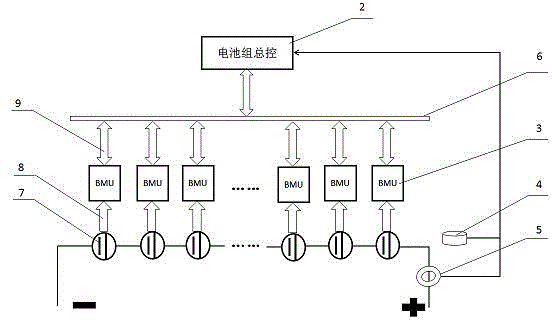

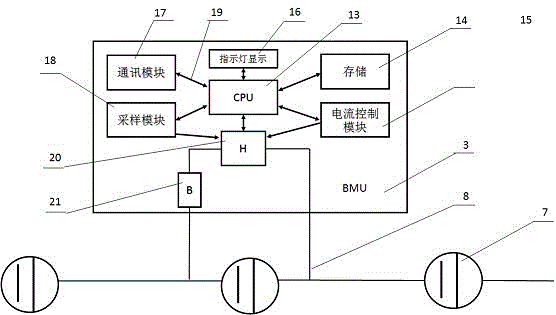

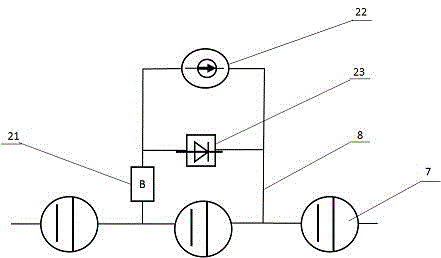

[0010] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments. Referring to the accompanying drawings, an automatic gapless bypass system for battery packs includes single battery management units 3 distributed and installed on each battery 7, and a battery pack master control unit 2 for unified management of all single battery management units 3, It is characterized in that: the single battery management unit 3 is directly connected to each battery 7 through two positive and negative sampling harnesses 8, each battery 7 is equipped with a single battery management unit 3, and all the single battery management units 3 are hung on the 485 communication harness 9 After the network bus 6 is connected to the battery pack master control unit 2, at the same time, the current sensor module 5 reports the discharge current of the entire battery pack 7, and the temperature sensor module 4 communicates the amb...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com