Quick wire connecting device and live wire connecting structure

A quick connection and wire technology, applied in the direction of conductive connection, connection, coupling device, etc., can solve the problems of difficult connection and installation of drain wires, and achieve the effects of light weight, strong practicability, and firm clamping

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

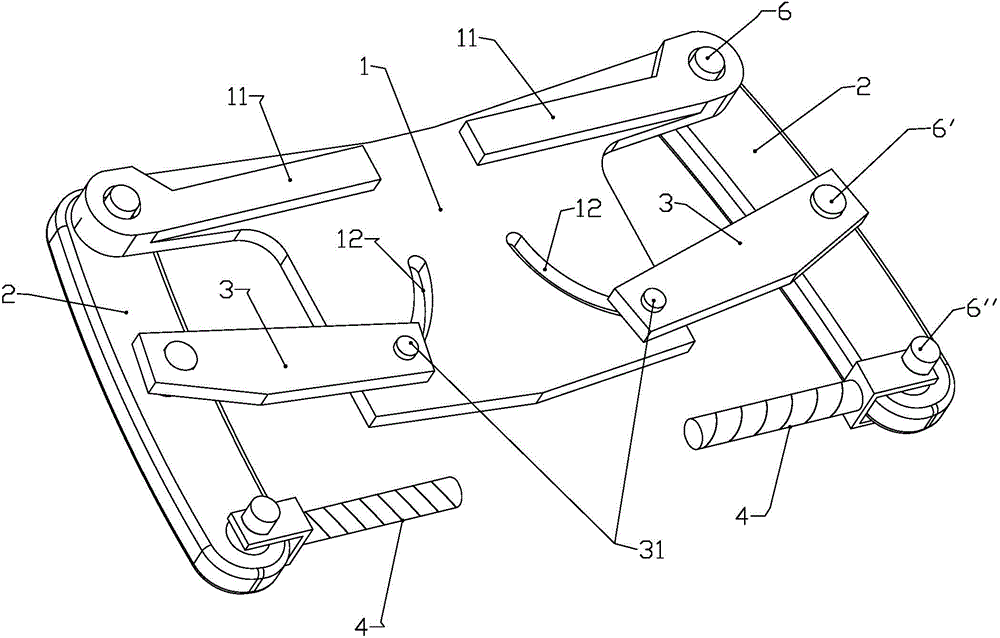

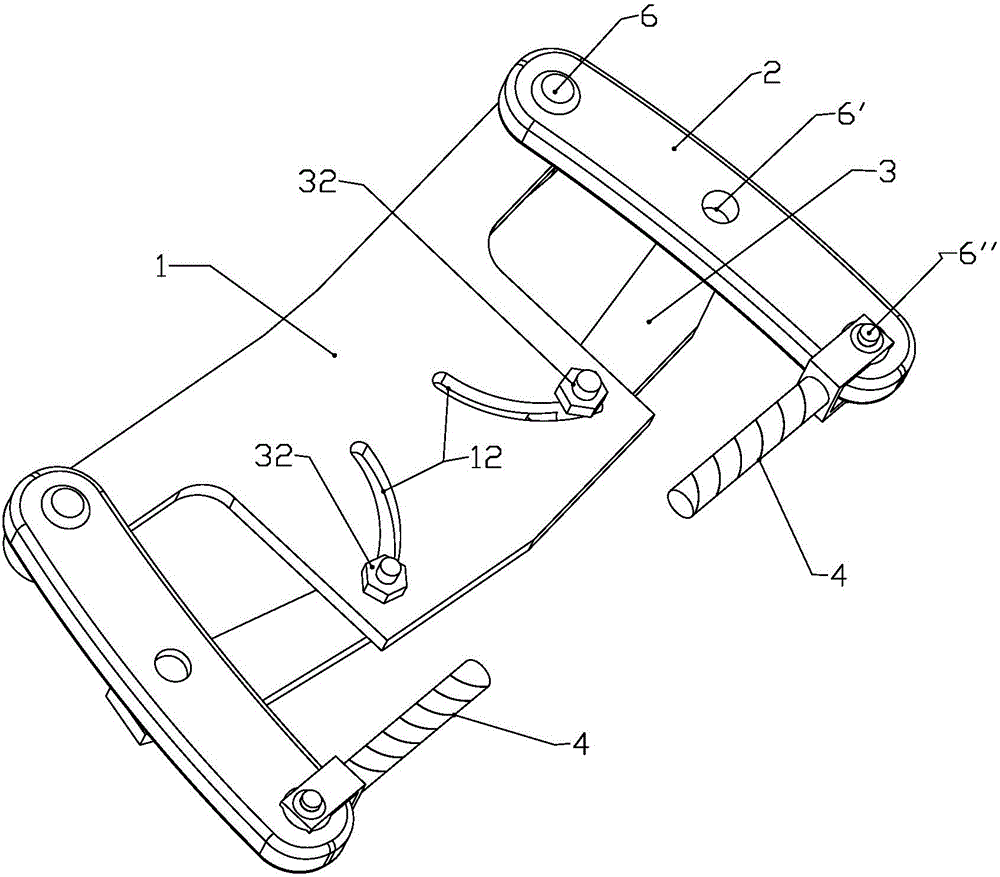

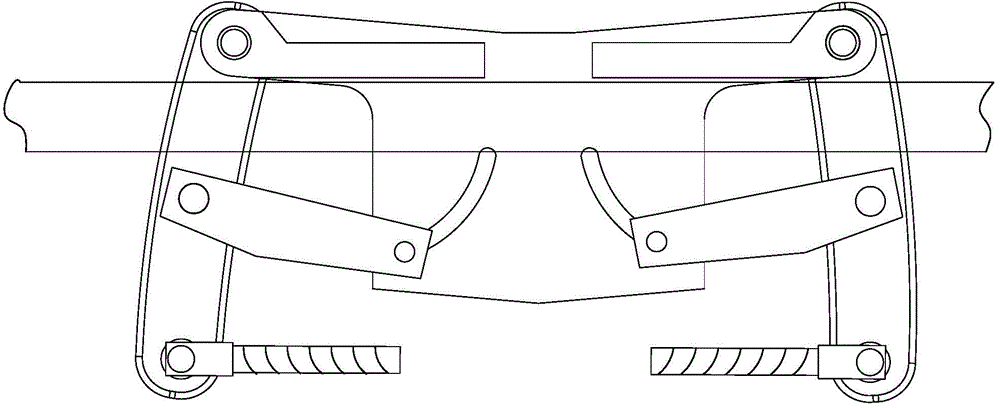

[0029] Such as Figure 1 to Figure 5 As shown, a wire quick connection device is composed of the following parts.

[0030] The static pressure plate 1 of the aluminum alloy casting has a T-shaped profile as a whole. On the front top of the static pressure plate, there are jaw protrusions 11 on the same straight line and circular holes arranged on both sides, wherein the jaw protrusions and the movable The pressing plate cooperates to form a jaw, and when the movable pressing plate moves closer to the protrusion of the jaw, a clamping action is formed, which can clamp the wire. Two arc-shaped guide grooves 12 arranged in a figure-eight shape are arranged symmetrically on the face plate of the static pressure plate.

[0031] The two vertical tie rods 2 are also aluminum alloy castings, and the top of each vertical tie rod is slip-knotted on the round holes on both sides of the static pressure plate through round pins 6 to form a hinged connection. Round pin holes are respectiv...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap