Method for pulling in restoration pipe, and restored pipeline

A technology for repairing pipes and inspection holes, which is applied in the sewer pipeline system, pipeline laying and maintenance, pipes/pipe joints/pipe fittings, etc., and can solve problems such as reduced load bearing capacity, road subsidence, and insufficient drainage capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

[0061] Hereinafter, the present invention will be described in detail based on the embodiments shown in the drawings.

[0062] [1] Inspection of drainage channels

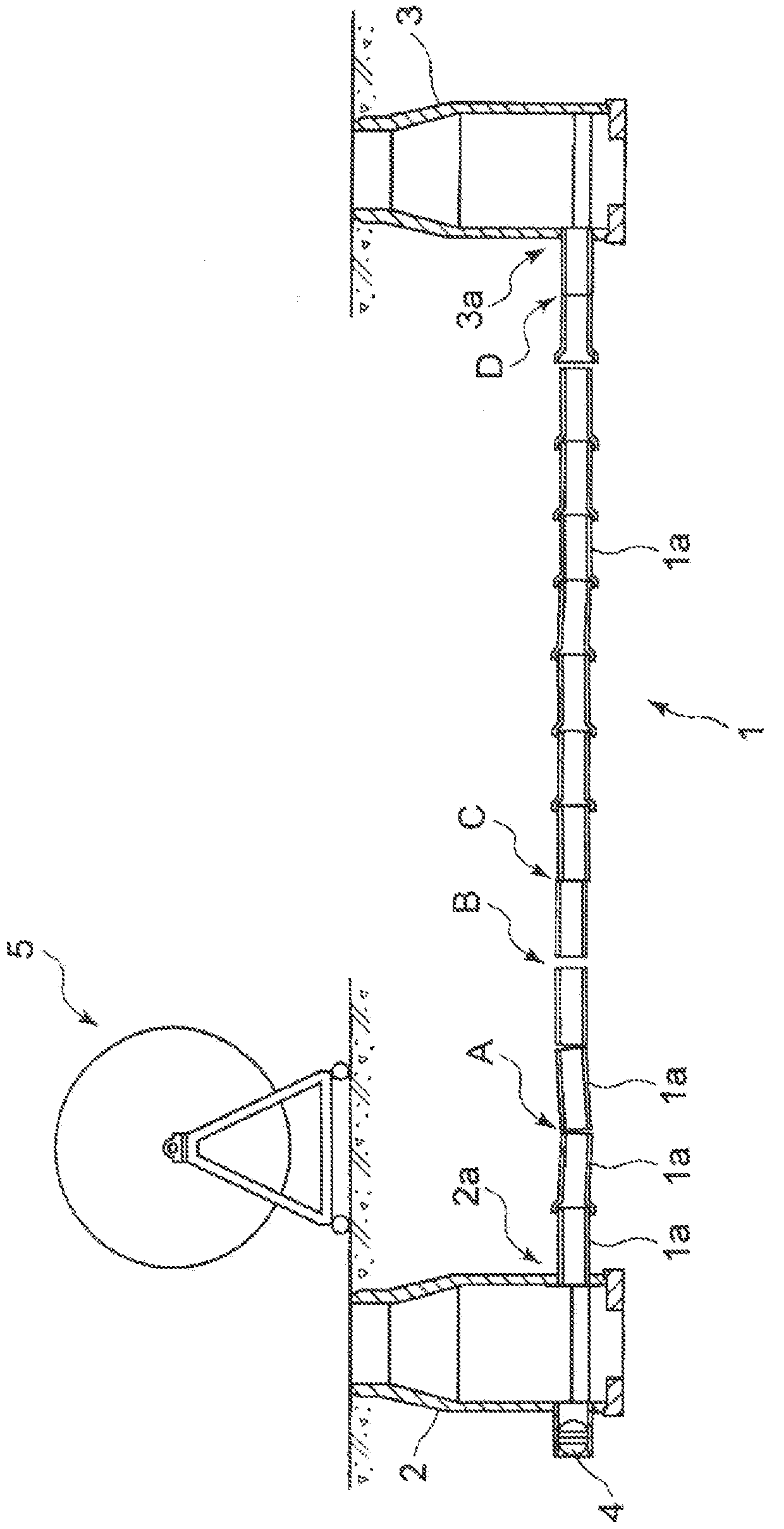

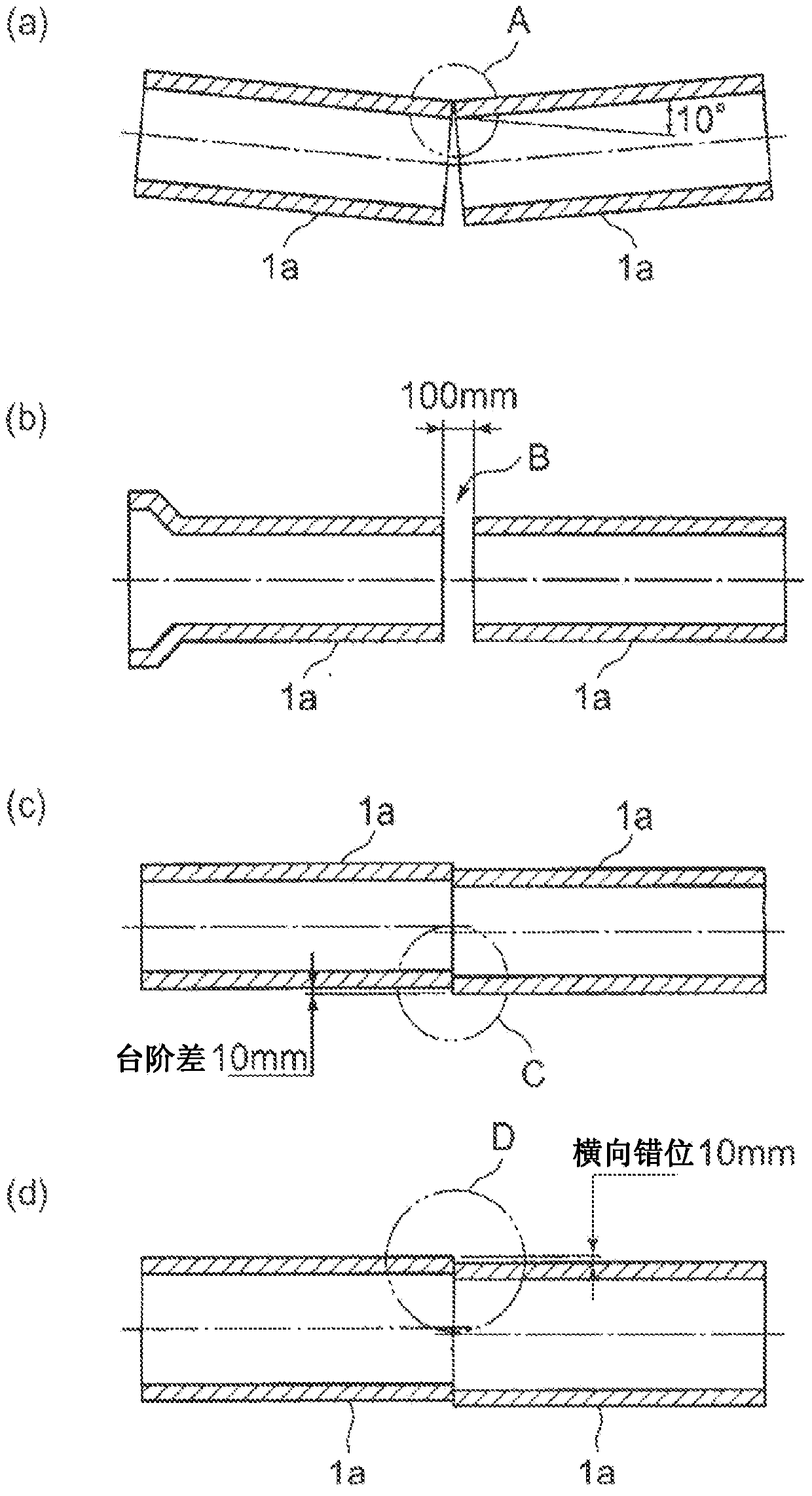

[0063] figure 1 It shows a deteriorating piped drainage channel to which the repairing pipe introduction method of the present invention is applied.

[0064] figure 1 Among them, the drainage channel 1 is formed by connecting a plurality of concrete drainage pipes 1 a and burying them in soil. One end of the drain passage 1 is connected to, for example, a lower opening 2 a provided at a lower portion of the upstream manhole 2 . The other end of the drain passage 1 is connected to a lower opening 3 a provided at a lower portion of the downstream manhole 3 .

[0065] When repairing the above-mentioned drainage channel 1, the inspection of the drainage channel 1 is carried out first.

[0066] Specifically, a high-pressure cleaning vehicle is placed, and the inside of the drainage channel 1 to be repaired is cle...

Deformed example 1

[0157] In Modification 1, the diagnosis process and the excavation process are performed before the simulation introduction process of the first embodiment.

[0158] In the diagnosis step, a diagnostic tool, which will be described later, is passed through the drainage channel 1 in order to detect a narrow portion in the drainage channel 1 . In addition, in the diagnostic process, it is preferable to insert a camera from behind the diagnostic tool, and to operate while checking the passing state of the diagnostic tool.

[0159] In the excavation step, an excavator is inserted into a narrow portion in the drain passage 1 detected in the diagnosis step, and the inner wall of the drain passage 1 is cut to expand the narrow portion.

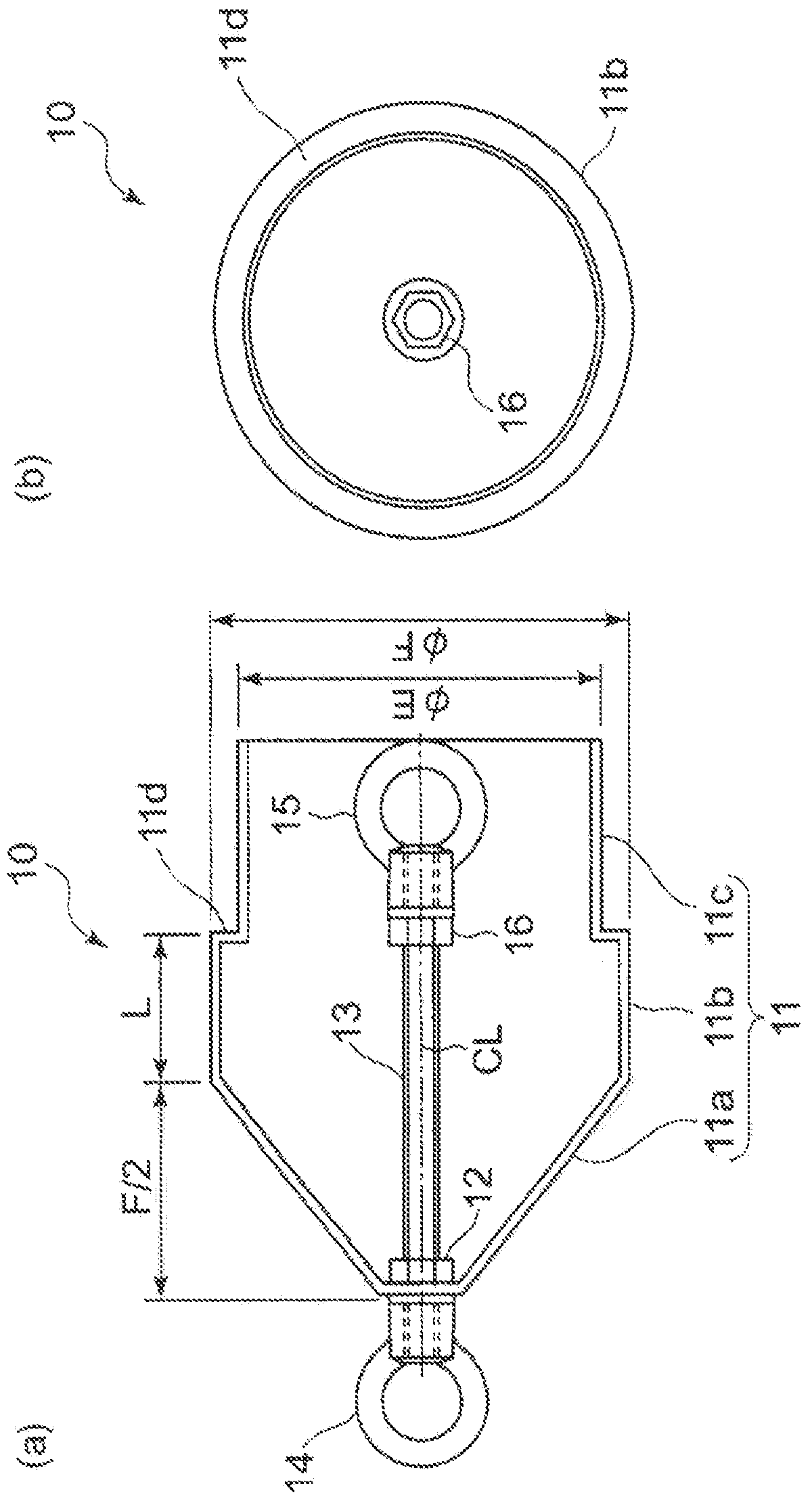

[0160] [1]Diagnostic tool

[0161] Figure 11 It is an external view of a diagnostic tool 60 according to Modification 1. FIG. Figure 11 Among them, the diagnostic tool 60 of Modification 1 has a tool body 61 made of a metal member made of iron o...

Embodiment approach 2

[0187] [1] Inspection of drainage channels

[0188] Figure 13 It represents a deteriorating piped drainage channel to which the pipeline repair method of the present invention is applied.

[0189] Figure 13 Among them, the drainage channel 201 is formed by connecting a plurality of concrete drainage pipes 201a and burying them in soil. One end of the drain passage 201 is connected to, for example, a lower opening 202 a provided below the most upstream manhole 202 . The other end of the drain passage 201 is connected to a lower opening 203a provided below the manhole 203 on the downstream side.

[0190] When repairing the above-mentioned drainage channel 201, the inspection of the drainage channel 201 is performed first.

[0191] Specifically, a high-pressure cleaning vehicle is arranged near the manhole 203 on the downstream side, and the inside of the drainage channel 201 is cleaned with high-pressure water (cleaning step).

[0192] Next, a self-propelled camera (not s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com