A riveting jig for a sealed contactor with an elastic reed moving contact piece assembly

An elastic reed and sealing contact technology, applied in the direction of manufacturing tools, metal processing equipment, feeding devices, etc., can solve the problems of inability to guarantee dimensional accuracy, inability to rivet, and large safety hazards, so as to reduce work-related injuries and ensure riveting Quality and work efficiency improvement effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

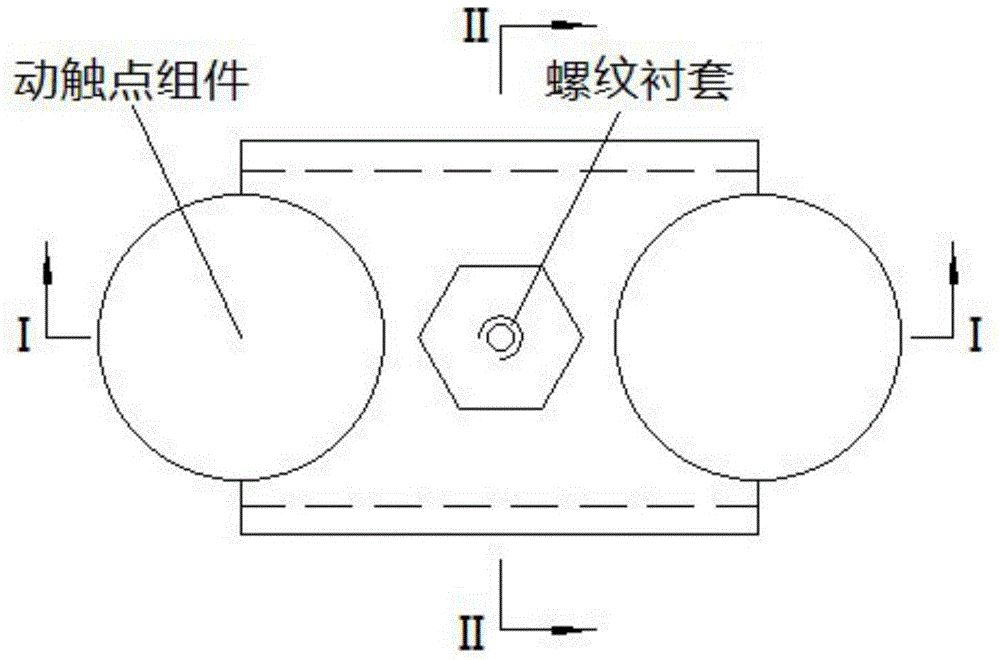

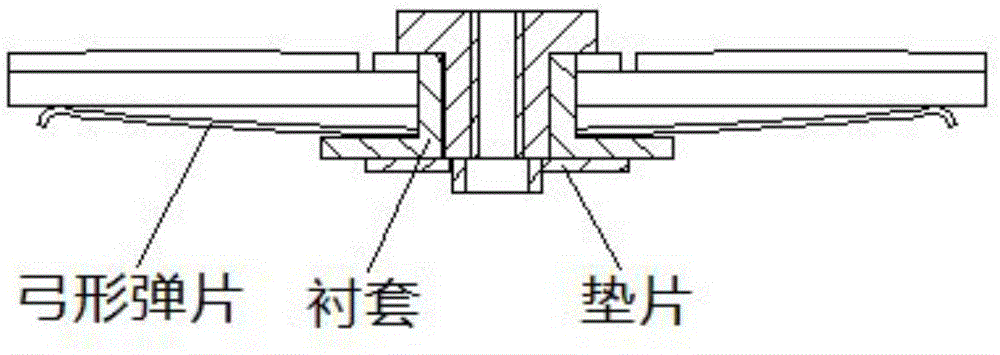

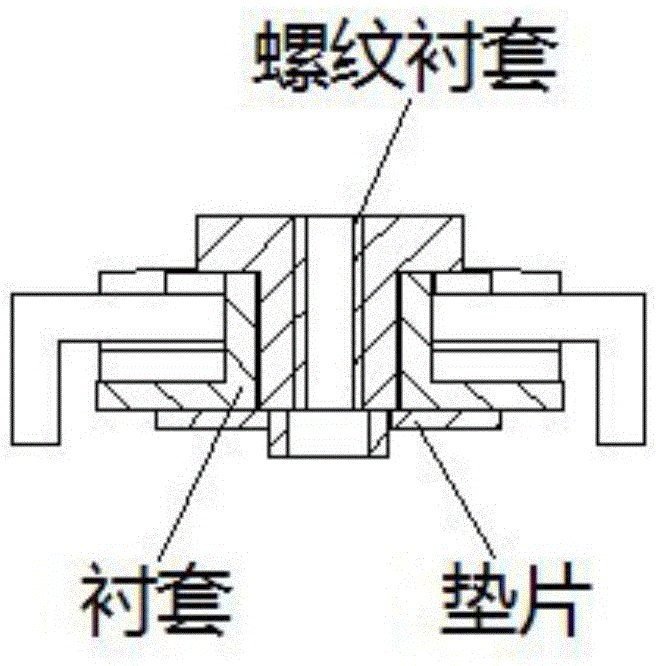

[0037] Embodiment: need riveting such as figure 1 , 2 When using the moving contact piece assembly with elastic reed shown in 3, first follow the Figure 1-3 Install the movable contact assembly, the threaded bushing, the bow-shaped shrapnel, the bushing and the gasket in place respectively, and then place the assembled workpiece 27 on the fixed seat 19 in the riveting jig provided by the present invention, and the position to be riveted is located at The bottom of the workpiece 27; at this time, the handle 24 is horizontal to the right, and the highest point of the top of the cam 12 is located on the left side. Under the action of the cam 12 and the pressure spring 17, the left end of the pressing plate 13 rises, that is, the pressing plate 13 revolves around the rotating shaft 15 on the support. Rotate clockwise on the plate 14 until the bottom surface of the right end of the pressing plate 13 contacts the top of the cam 12, as shown Figure 6 The state shown (the handle 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com