Hollow wooden column hydraulic rounding machine

A technology of wooden columns and circular knitting machines, applied to wood processing equipment, manufacturing tools, etc., can solve the problems of no processing method and no application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

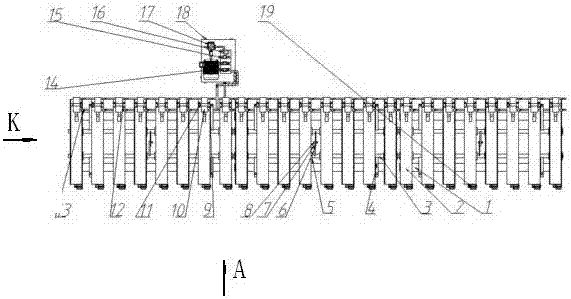

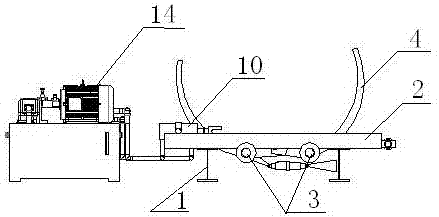

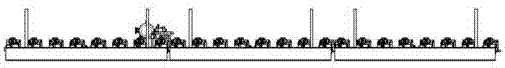

[0007] A preferred embodiment of the present invention, as shown in the figure, the support 2 is placed above the bottom beam 1, the hydraulic cylinder 10 and the belt tensioner 19 are respectively placed at both ends of the support, the hollow wooden column to be spliced is placed on it, and the bottom beam 1 is made of I-shaped steel, located below the bracket 2, two round pipes 3 are installed on the inner sides of the two bottom beams 1, the upper part of the ring-shaped baffle 5 is fixed on the bracket, and the inner sides of the two bottom beams 1 are installed. There are two round pipes 3 passing through the block, the round pipes 3 mainly play a transmission role, one end of the arm hydraulic cylinder 8 is fixed on the side wall of the bottom beam through the fixing frame 9, and the other end is fixed on the round pipe through the fixing frame 9 , through the movement of the hydraulic cylinder to drive the round pipe to rotate; one end of the movable support frame 6 a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com