Purification method for boron trichloride

A technology of boron trichloride and purification method, which is applied in the direction of boron halide compounds, etc., and can solve problems such as difficulty in meeting purification requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

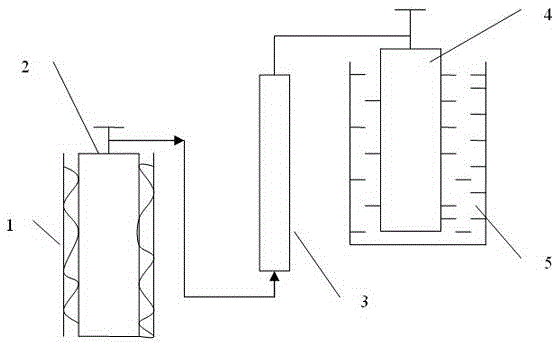

[0012] Heat the boron trichloride raw material steel cylinder 2 with a heating belt 1 at 35°C to between 25°C and 35°C to fully vaporize boron trichloride, control the flow rate of boron trichloride gas to 10L / min, pass through a diameter of 5cm, and a height of 50cm, boron carbide reaction layer 3 with a temperature of 850°C, the gas after the reaction is cooled by a -20°C low temperature box 5, and collected in a product bottle 4.

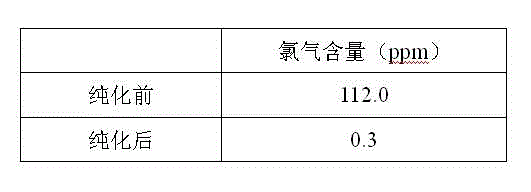

[0013] The chlorine content comparison before and after purification is as follows:

[0014]

Embodiment 2

[0016] Operating condition is the same as embodiment 1, and chlorine content before and after purification contrasts as follows:

[0017]

Embodiment 3

[0019] Operating condition is the same as embodiment 1, and chlorine content before and after purification contrasts as follows:

[0020]

[0021] In the above example, although the chlorine content in the boron trichloride before purification is different (increased by an order of magnitude), after passing through the boron carbide reaction layer under the same conditions, the chlorine impurity content can be reduced to below 1ppm, which fully proves the effectiveness of the present invention. sex.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com