A kind of method of extracting sennoside A in rhubarb tangut

A technology of sennoside and rhubarb, applied in chemical instruments and methods, preparation of sugar derivatives, sugar derivatives, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

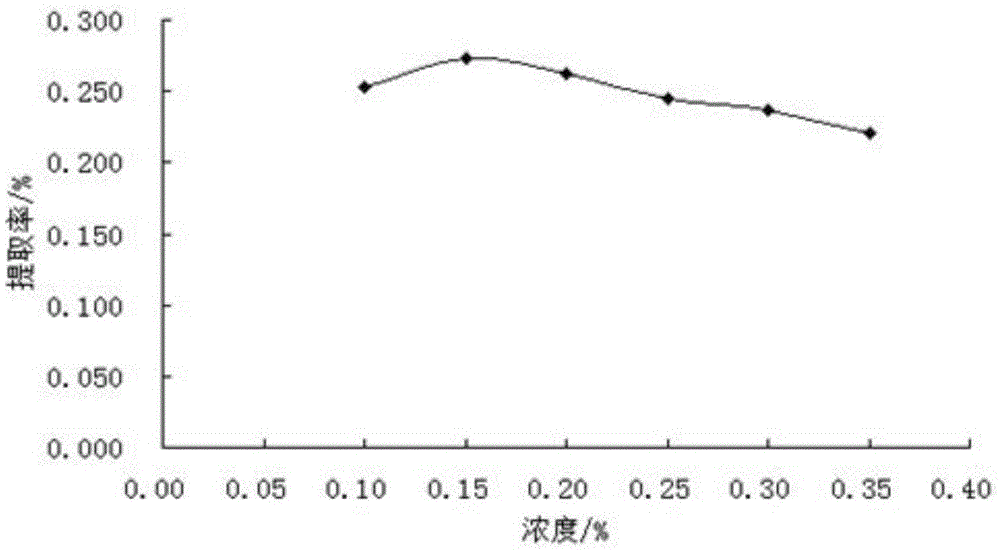

[0022] Example 1NaHCO 3 Effect of Solution Concentration on Extraction Rate of Sennoside A

[0023] Weigh 6 parts of Tangut rhubarb powder, each 0.25g, add 50mL of NaHCO with mass percent concentration of 0.1%, 0.15%, 0.2%, 0.25%, 0.3%, and 0.35% respectively 3 solution, weighed, recorded the weight, then ultrasonicated for 40min under the same conditions, allowed to cool, and each NaHCO 3 The solution is made up to weight. Filtration, sample injection, record the chromatogram, and calculate the extraction rate of sennoside A as figure 1 ,From figure 1 It can be seen that with NaHCO 3 With the increase of solution concentration, the obtained sennoside A also increases, when NaHCO 3 When the concentration of the solution reaches 0.15%, the extraction rate is the highest, and then with NaHCO 3 As the concentration of the solution continued to increase, the extraction rate decreased gradually.

Embodiment 2

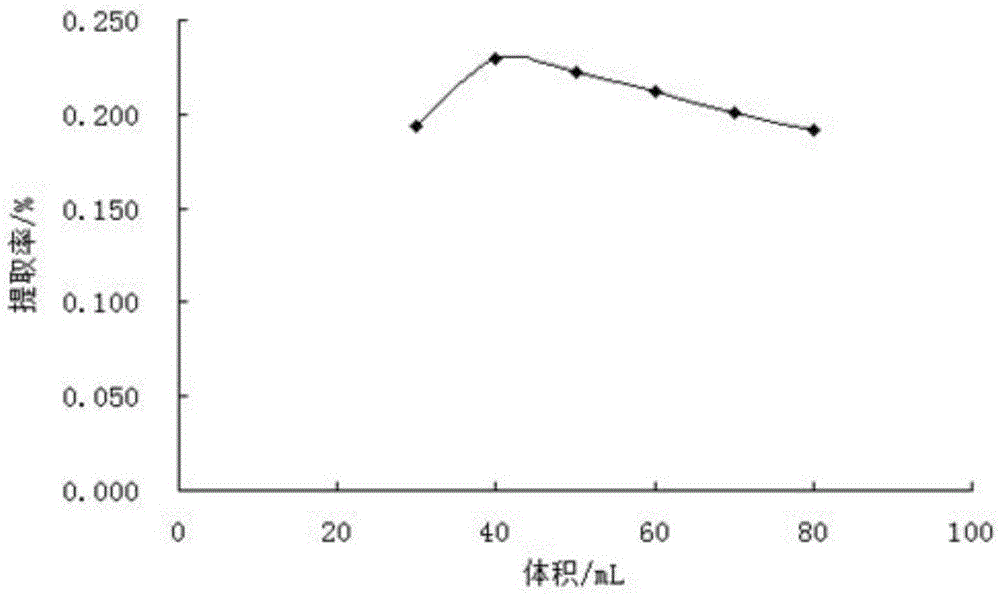

[0024] Example 2NaHCO 3 The Effect of Solution Volume on the Extraction Rate of Sennoside A

[0025] Take by weighing 6 parts of Tangut rhubarb powder, every part of 0.25g, put into the NaHCO that is equipped with mass percentage concentration and be 0.1%. 3 Put the solutions in 30mL, 40mL, 50mL, 60mL, 70mL, 80mL conical flasks, weigh them, sonicate for 40min under the same conditions, let cool, and use each NaHCO 3 The solution is made up to weight. Filtration, sample injection, record the chromatogram, and calculate the extraction rate of sennoside A as figure 2 ,Depend on figure 2 It can be seen that with NaHCO 3 As the volume of the solution increases, the obtained sennoside A also increases. When NaHCO 3 The extraction rate was the highest when the solution volume reached 40mL, and then with NaHCO 3 As the volume of the solution continued to increase, the extraction rate decreased gradually.

Embodiment 3

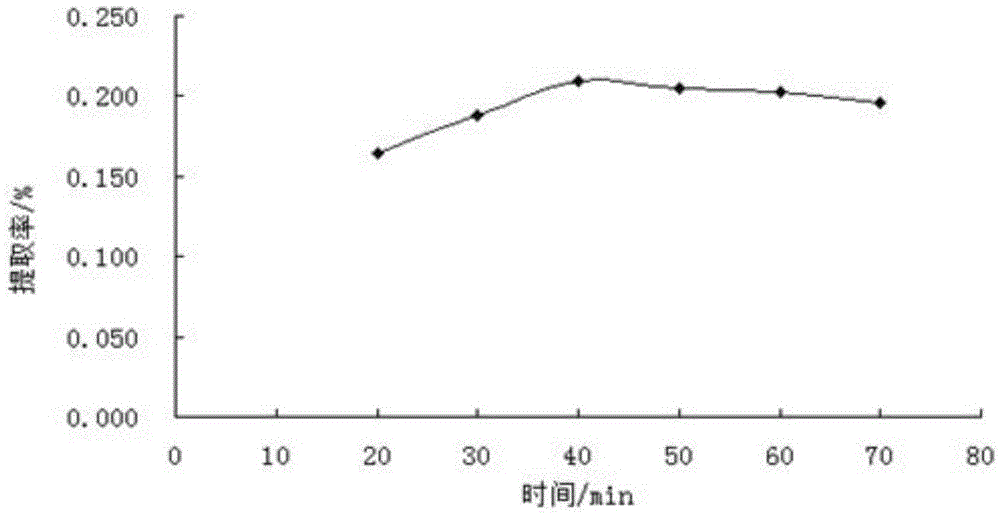

[0026] The influence of embodiment 3 ultrasonic extraction time on sennoside A extraction rate

[0027] Weigh 6 parts of Tangut rhubarb powder, each 0.25g, put into 50mL of NaHCO with a mass percentage concentration of 0.1%. 3 Put the solution in an Erlenmeyer flask, weigh it, and ultrasonicate it for 20, 30, 40, 50, 60, and 70 minutes under the same conditions, let it cool, and use each NaHCO 3 The solution is made up to weight. Filtration, sample injection, record the chromatogram, and calculate the extraction rate of sennoside A as image 3 ,Depend on image 3 It can be seen that as the ultrasonic extraction time increases, the obtained sennoside A also increases, and the extraction rate is the highest when the ultrasonic extraction time reaches 40 min, and then gradually decreases as the ultrasonic extraction time continues to increase.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com