thin heat pipe

一种薄型热管、管体的技术,应用在热管领域,能够解决薄型热管损坏、圆柱形热管难以设置、中央区域易产生凹陷等问题,达到增加强度的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

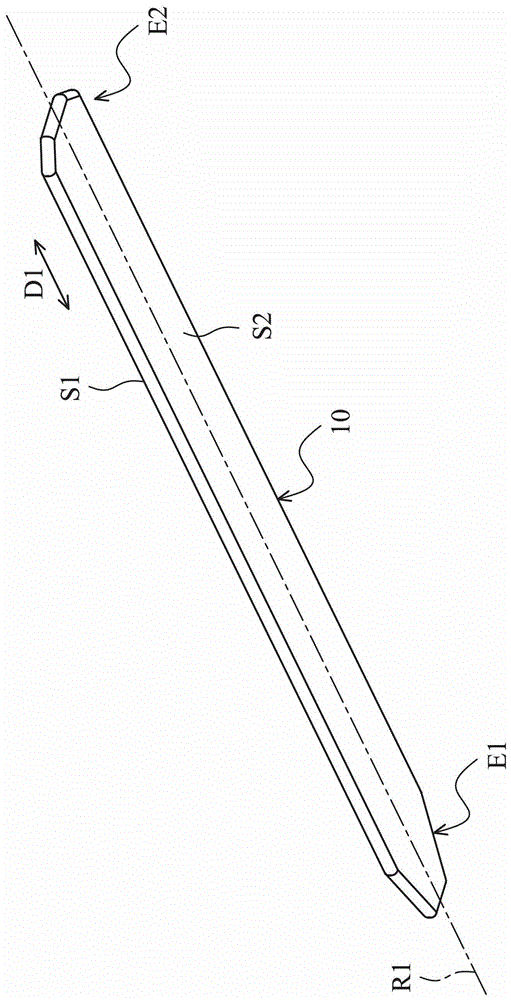

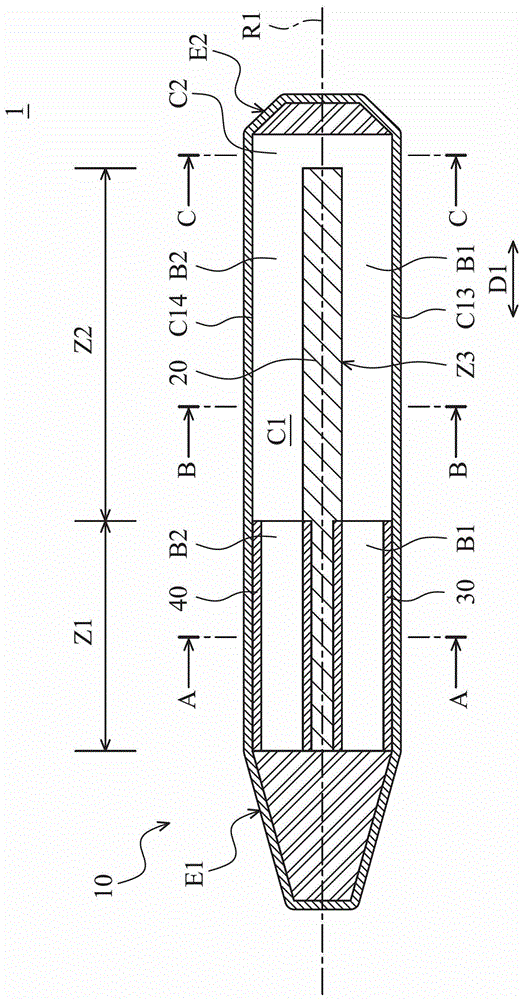

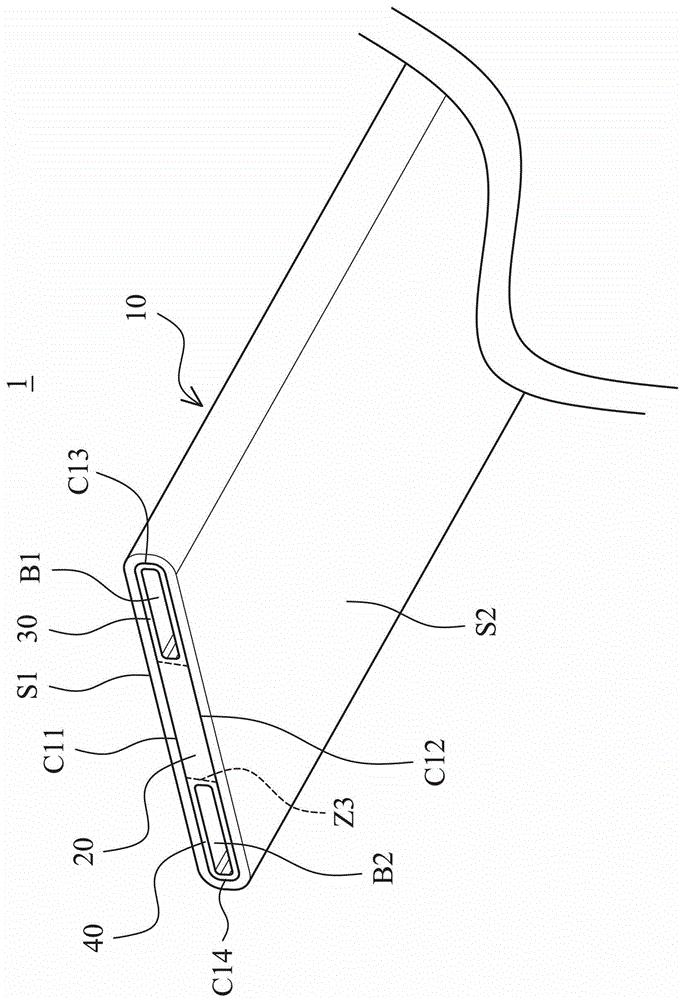

[0025] figure 1 It is a perspective view of the thin heat pipe 1 of the present invention, figure 2 It is a longitudinal sectional view of the thin heat pipe 1 of the present invention. The thin heat pipe 1 includes a pipe body 10 , a main capillary structure 20 , a first capillary structure 30 and a second capillary structure 40 . The tube body 10 is a flat sealing structure. The width of the pipe body 10 may be three times, four times, or more than five times the thickness of the pipe body 10 . The tube body 10 may have a first outer plane S1 and a second outer plane S2, and the first outer plane S1 is parallel to the second outer plane S2. The tube body 10 may include heat-conducting materials such as metal, and extends along an extending path R1. In this embodiment, the extension path R1 is a straight line and extends along an extension direction D1. In another embodiment, the extending path R1 may include a straight section and / or a curved section.

[0026] The tub...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com