Device and methodpreventing drying in pipe

A stirring device and pipeline technology, which is applied in the field of grouting structural components, can solve the problems of less grouting pipe grout, poor sealing quality of the furnace cover, and insufficient grouting, etc., and achieves low equipment investment, convenient operation, and low cost Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

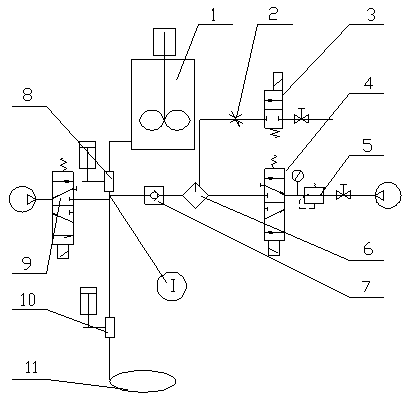

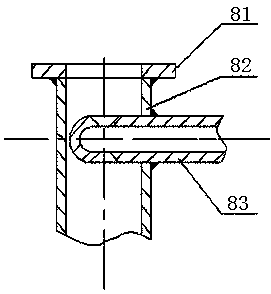

[0019] Embodiment 1: see Figure 1-Figure 3 , a device for preventing dryness in a pipe, the device includes an automatic grouting system and a control valve, the automatic grouting system includes a stirring device 1, a grouting ball valve 8, a grouting pneumatic reversing valve 9, and a grouting ball valve 10 And an annular grouting ring 11, the control valve includes a throttle valve 2, an electromagnetic water valve 3, a pneumatic reversing valve 4, a pressure reducing valve 5, a lubricator 6 and a one-way valve 7, and the stirring device passes through the pipeline Connect the grouting ball valve 8, the grouting ball valve 8 is connected to the grouting ball valve 10 and the annular grouting ring 11 through the pipeline, the one-way valve is sequentially connected to the throttle valve and the electromagnetic water valve through the lubricator, and the other way is sequentially Connect the pneumatic reversing valve and the pressure reducing valve. The lower flange 81, the...

Embodiment 2

[0020] Example 2: see Figure 1-Figure 4 , to prevent the method of drying in the tube, the method is as follows,

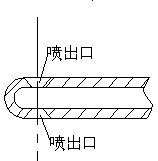

[0021] Step 1: Install the equipment, install the equipment needed to prevent the dry-out device in the coke oven automatic grouting pipeline into the automatic grouting equipment, install the nozzle pipe with a spray angle under the ball valve for discharging grout, and align the nozzle under the ball valve and the pipe ;

[0022] Step 2: Clean and add water. After the coal stoker returns to the waiting position after adding coal, the electromagnetic water valve is energized, and the water in the water tank enters the lubricator through the electromagnetic water valve and the throttle valve. When the water level in the lubricator reaches 2 / 3-1 / 2, the electromagnetic water valve powers off and stops adding water, and the appropriate amount of water is determined by the verification of the cleaning effect;

[0023] Step 3: Cleaning and purging, after the water i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com