A cooling device and a refrigerator

A technology of a heat sink and a refrigerator, applied in the field of heat dissipation, can solve the problems of low refrigeration efficiency of semiconductors, and achieve the effect of reducing internal space restrictions and improving stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

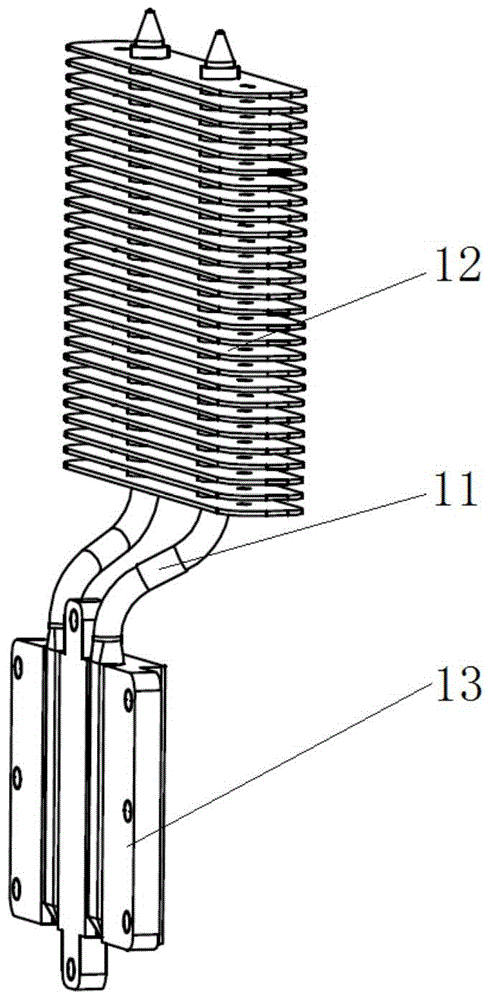

[0044] This embodiment provides a heat dissipation device for dissipating heat from the hot end of the semiconductor cooling fin. Specifically, the heat dissipation device includes a heat pipe and a radiator. Among them, the heat pipe has an evaporation section (such as figure 2 Evaporation section 211, evaporation section 212) and condensation section in. Wherein, there are at least two evaporating sections, and a condensing section is arranged between any two adjacent evaporating sections. The radiator is arranged on the condensing section of the heat pipe, and is used to radiate heat to the gaseous working medium in the condensing section to liquefy it.

[0045] Wherein, there are three heat pipes, and the evaporation section of the heat pipe is used to connect the hot end of the semiconductor cooling sheet (that is, different evaporation sections are connected with different semiconductor cooling sheet hot ends, or different evaporation sections are connected with differe...

Embodiment 2

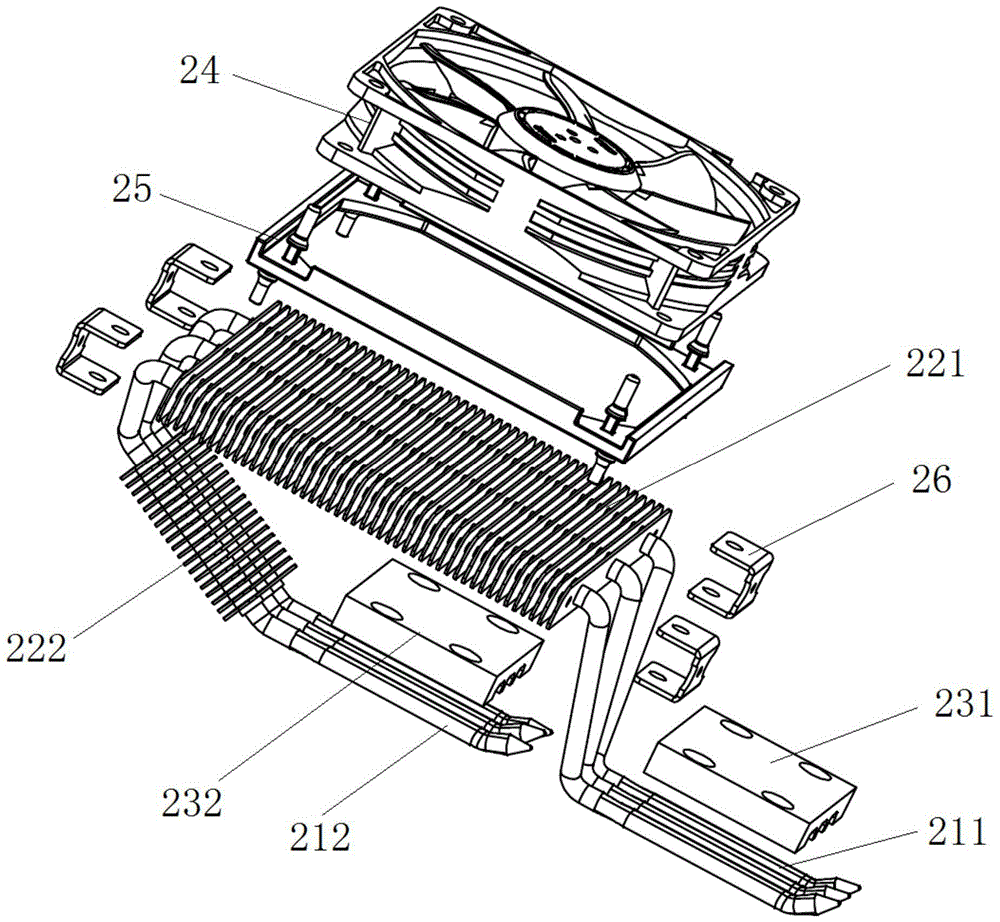

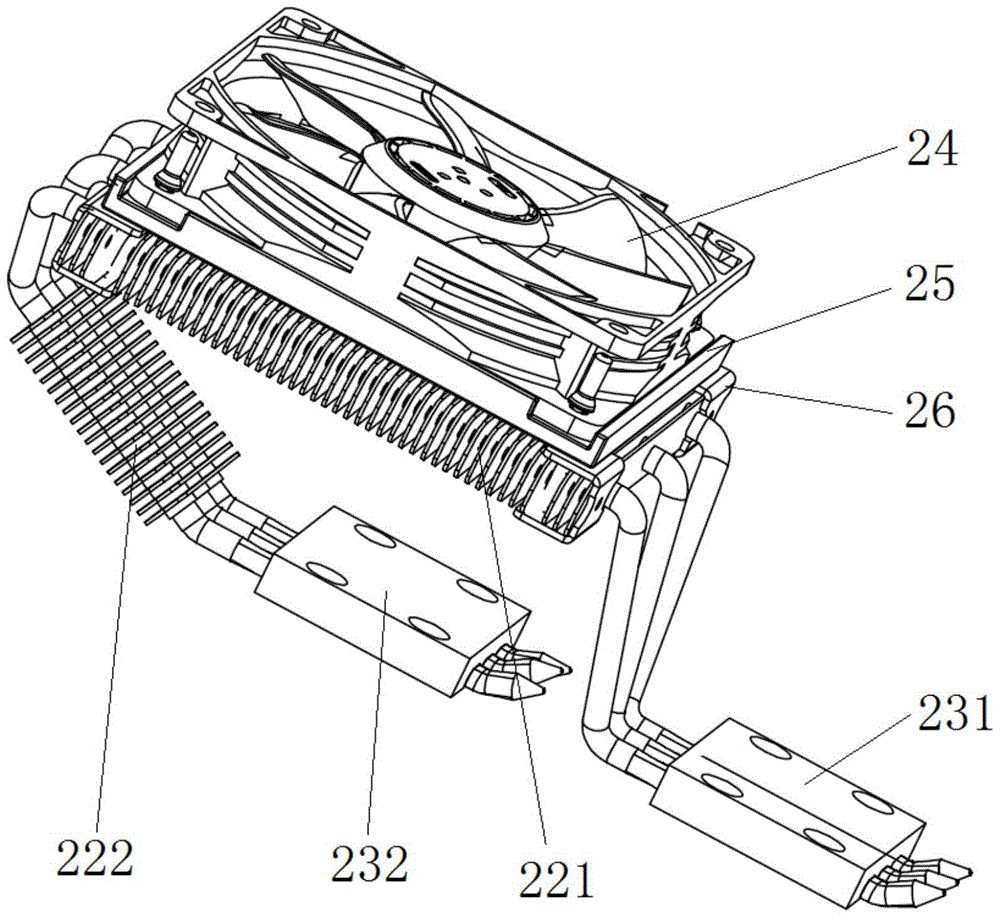

[0049] Such as figure 2 , image 3 and Figure 4 As shown, this embodiment provides a heat dissipation device for dissipating heat from the hot end of the semiconductor cooling fin. Compared with the previous embodiment, there are two evaporation sections on the heat pipe in this embodiment, one of which is the first The evaporation section 211, and the other is the second evaporation section 212. The first evaporating section 211 is located at one end of the heat pipe, the second evaporating section 212 is located at the other end of the heat pipe, and the condensing section is located between the first evaporating section 211 and the second evaporating section 212 . The radiator is set on the condensation section of the heat pipe (see figure 2 The cooling fin assembly 221, the cooling fin assembly 222 and the fan 24).

[0050] In this embodiment, the first evaporating section 211 and the second evaporating section 212 of the heat pipe are used to connect the hot end of...

Embodiment 3

[0053] Such as figure 2 , image 3 and Figure 4 As shown, this embodiment provides a heat dissipation device. Compared with Embodiment 2, the condensation section of the heat pipe in this embodiment includes a first condensation section and a second condensation section; wherein, the first condensation section and the second condensation section are in the form of The first setting angle β, where 0°<β≦90°; the second condensation section is located between the first condensation section and the second evaporation section 212 .

[0054] In this embodiment, the heat dissipation efficiency of the heat sink is further improved by dividing the condensation section into a first condensation section and a second condensation section, so that the first condensation section and the second condensation section cooperate to condense the gaseous working medium inside the heat pipe. Specifically, the second condensation section mainly condenses the gaseous working medium evaporated in ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com