Broken rotor bar detection based on current signature analysis of an electric machine

A rotor bar, electrical signal technology, used in motor generator testing, motor control, measuring electricity, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] Reference will now be made in detail hereinafter to exemplary embodiments of the invention, examples of which are illustrated in the accompanying drawings. Wherever possible, the same reference numbers are used throughout the drawings to refer to the same or like parts.

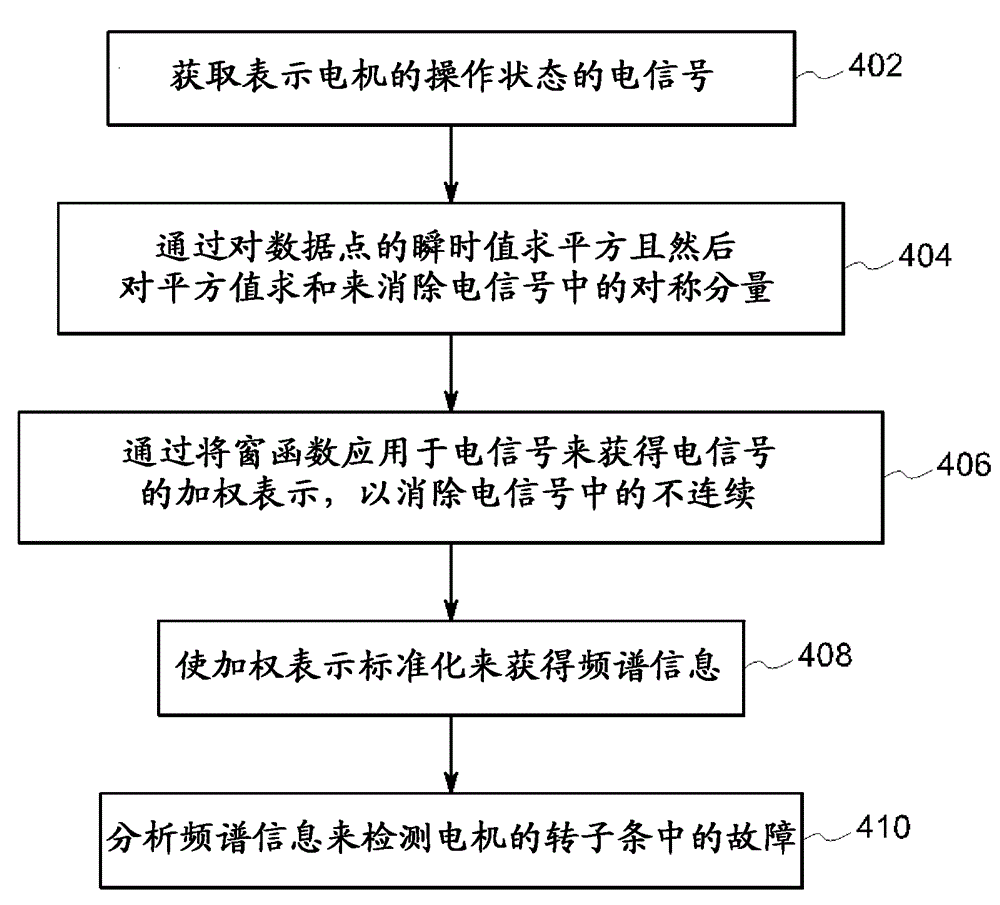

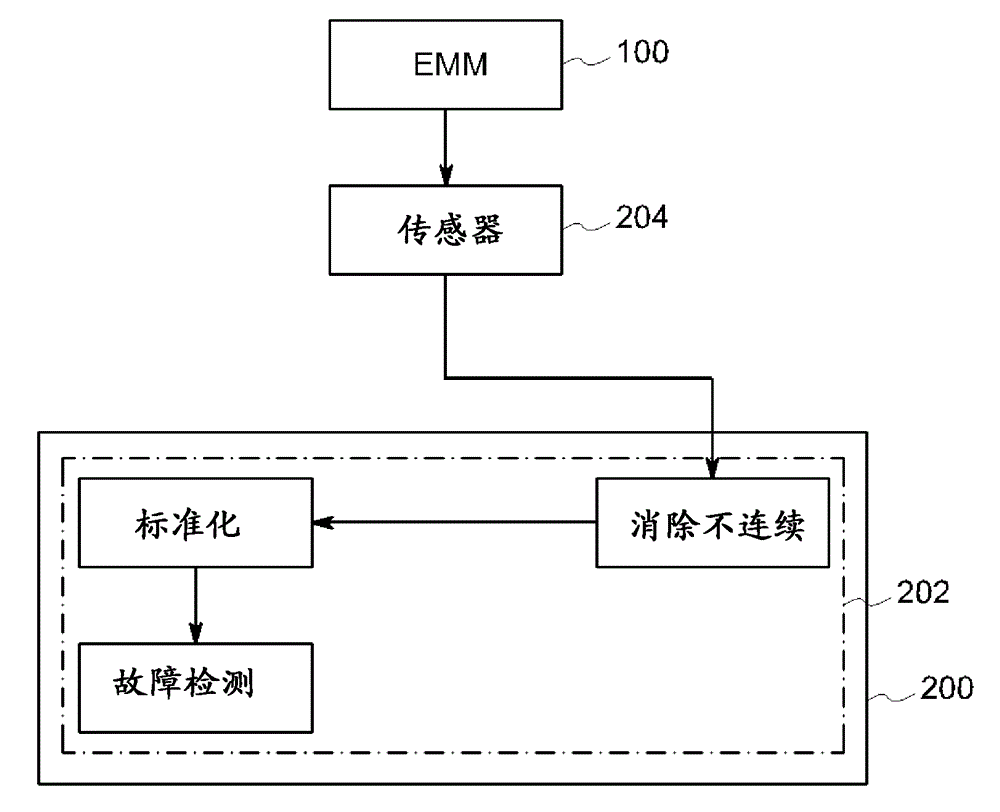

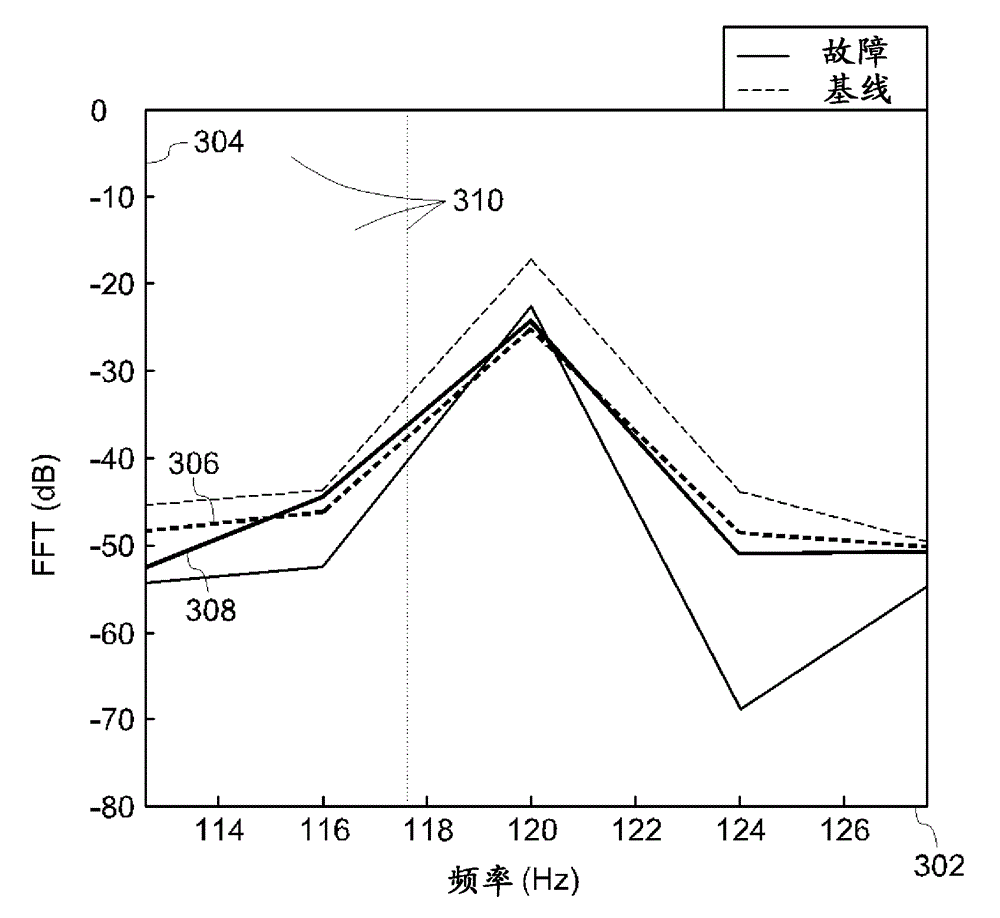

[0029] A spectral analysis based technique for high sensitivity detection of rotor broken bar faults in electromechanical machines (EMMs) is described herein. This technique provides for differentiating the condition of a faulty EMM rotor bar from a normal or acceptable condition based on a possibly subtle change in the magnitude of the electrical signature received from the EMM. The main components in electrical signals received from typical electromechanical machines are power fundamental and harmonics, eccentricity harmonics, slot harmonics, saturation harmonics, and other components from unknown sources, including environmental noise. Since such principal components exist both before and after the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com