Equipment fault warning and state monitoring method

A technology for equipment failure and status, applied in special data processing applications, instruments, electrical and digital data processing, etc., can solve problems such as difficulty in guaranteeing the integrity of prior knowledge, conflict resolution, poor generality, etc., to alleviate overfitting/underfitting The effect of fitting problems, improving accuracy, and strong adaptive ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0066] This embodiment takes the primary fan of unit 1# of a thermal power plant in the north as the monitoring object. The primary fan is an important auxiliary equipment of the power plant. It has a complex structure and many influencing factors. It is difficult to establish an accurate mathematical mechanism model, and it is prone to frequent failures. It conforms to the characteristics of the multivariate nonlinear system targeted by the present invention. Through the detailed elaboration of this embodiment, the implementation process of the present invention is further described.

[0067] The implementation steps of the fault warning and status monitoring of the primary fan equipment of a certain power plant in the embodiment of the present invention are as follows:

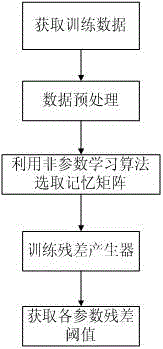

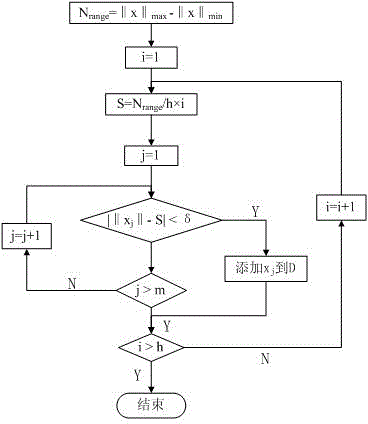

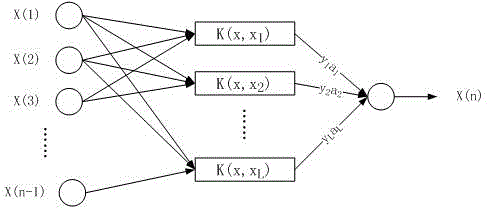

[0068] 1. Modeling process of equipment failure early warning and status detection system

[0069] (1) Obtain training data

[0070] There are 28 key parameters related to the safe operation of the prima...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com