Substrate with built-in electronic components

A technology for electronic components and built-in substrates, which is applied in the field of built-in substrates for electronic components, and can solve problems such as the influence of component functions and cracks

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 Embodiment approach ( pic 1

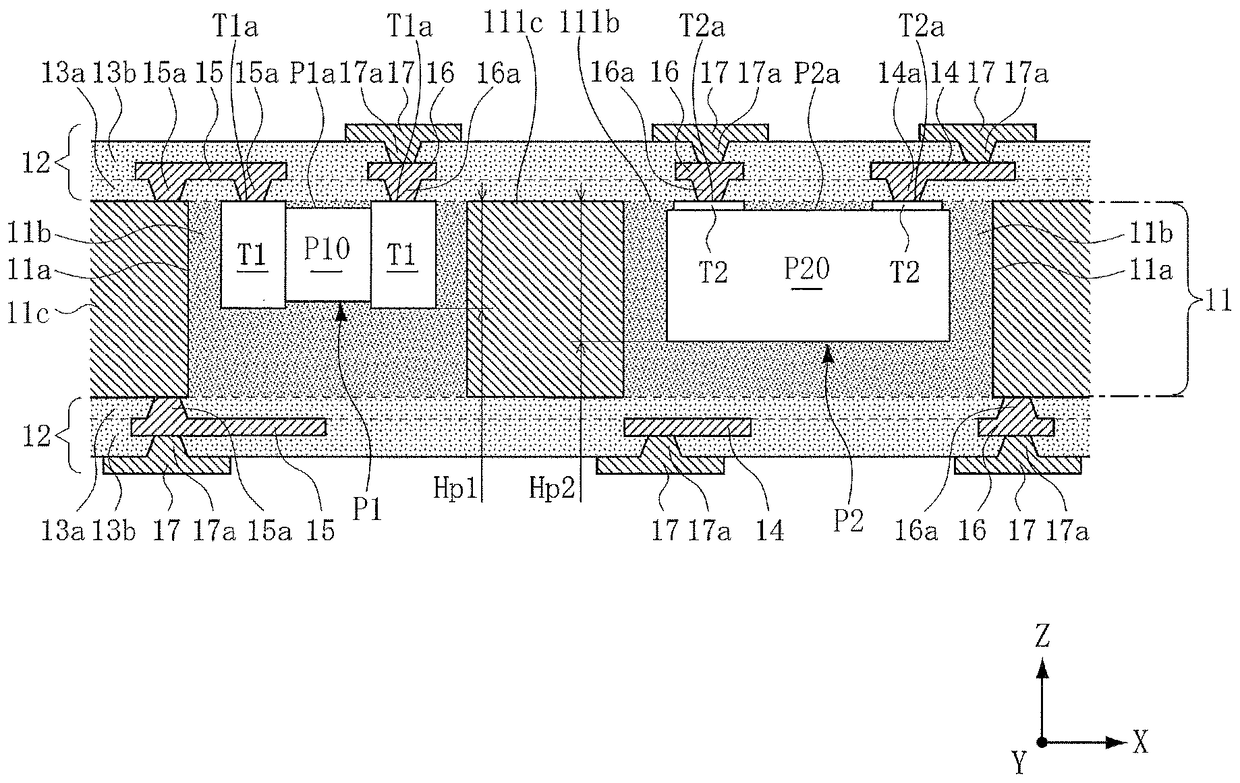

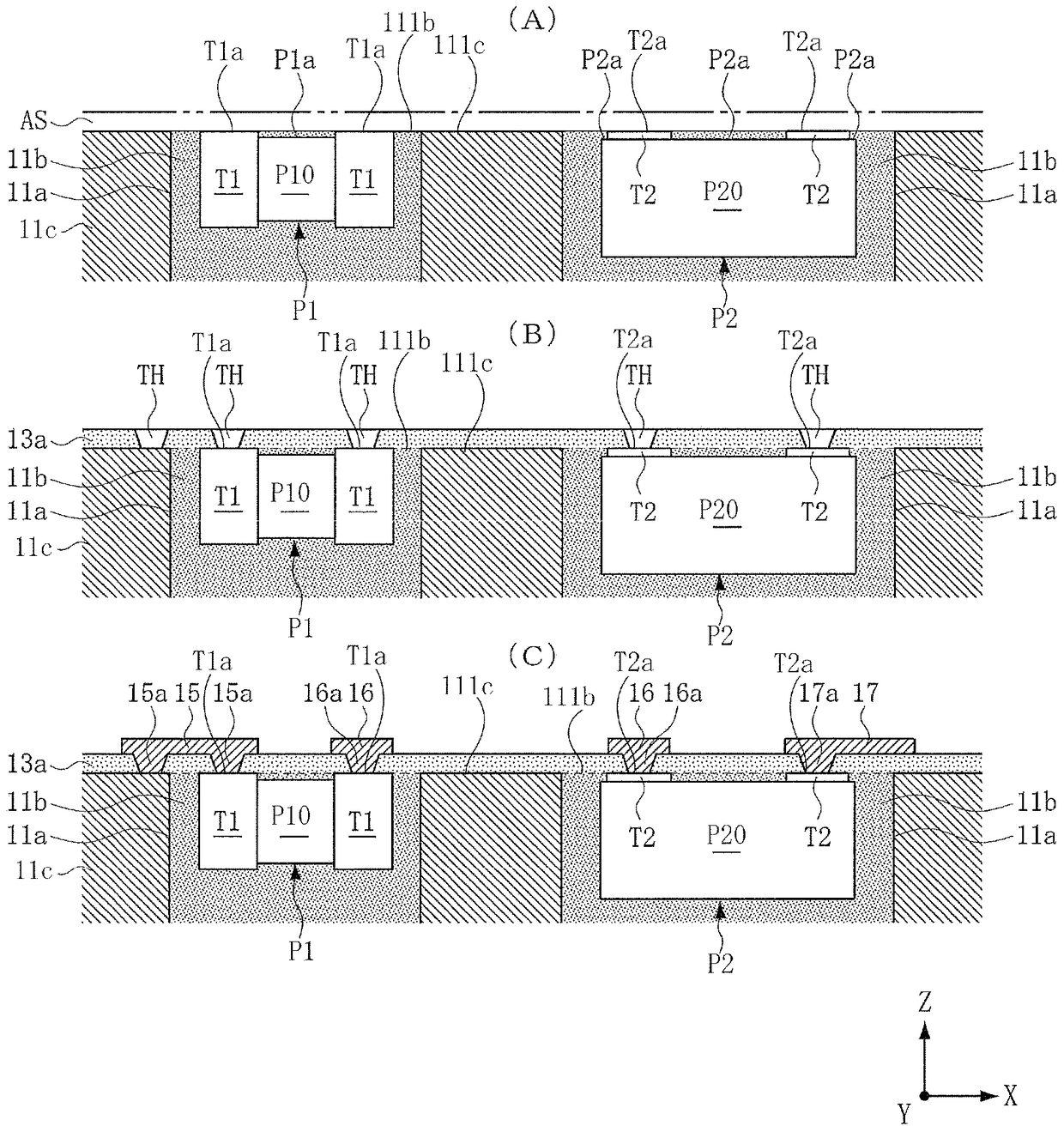

[0041] [The first embodiment ( figure 1 and figure 2 )]

[0042] figure 1 It is a vertical cross-sectional view of the electronic component built-in substrate according to this embodiment. in addition, Figure 1 ~ Figure 3 The X-axis direction, Y-axis direction, and Z-axis direction in the graph represent three vertical (coordinate) axis directions, the X-axis direction and the Y-axis direction represent the horizontal direction, and the Z-axis direction represents the thickness direction (up-down direction).

[0043] First, explain figure 1The basic structure of the substrate with built-in electronic components is shown. The electronic component built-in substrate has: a component storage layer 11; The build-up layers 12 are respectively provided on the other surface (lower surface) perpendicular to the (thickness direction).

[0044] The component housing layer 11 has two electronic components P1 and P2, an insulating covering part 11b, and a base material 11c. The ...

no. 2 Embodiment approach ( pic 3)

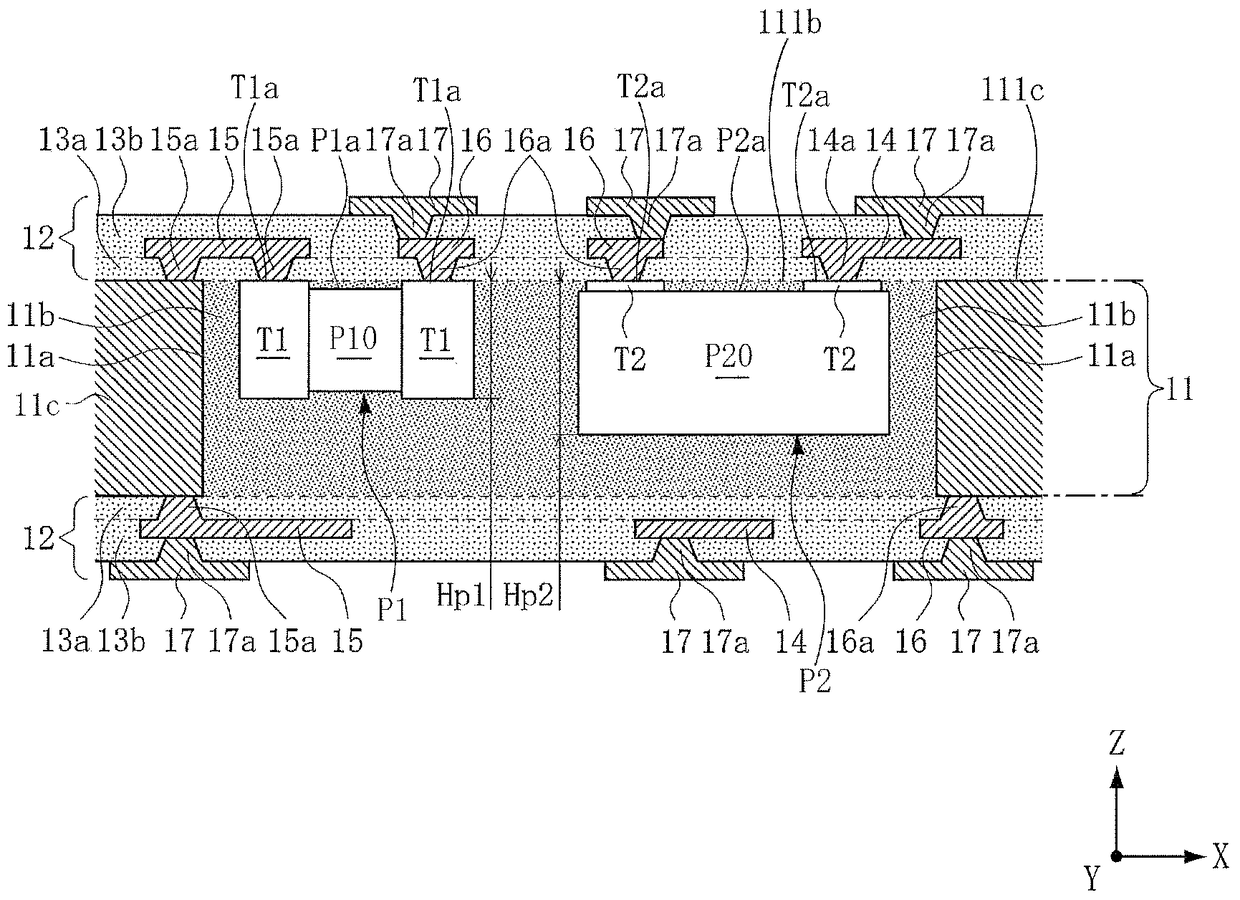

[0080] image 3 The electronic components shown are built into the substrate and figure 1 The shown electronic component built-in substrate differs in structure in that the component housing layer includes a plurality of electronic components accommodated in one cavity portion 11a. In addition, similarly to the first embodiment, the covering portion 11b and the electronic components P1, P2 are accommodated in the cavity portion 11a, and the covering portion 11b is filled with the two electronic components P1, P2 and the cavity portion. 11a between the gaps between the way and set. In addition, in the step of forming the component housing layer of the substrate with built-in electronic components (component placement step), in addition to inserting the two electronic components P1 and P2 into one cavity portion 11a and then filling the uncoated portion 11b, Except for the difference of the hardened material, the other processes are the same as those described above.

[0081]...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com