Support plate for flat membrane member

A support plate and flat membrane technology, applied in membrane technology, semi-permeable membrane separation, chemical instruments and methods, etc., can solve the problems of strengthening the side sealing, reducing the thickness of the support plate, reducing membrane pollution, etc., and reducing installation and production. cost, increase the difficulty of sealing, and improve the effect of processing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

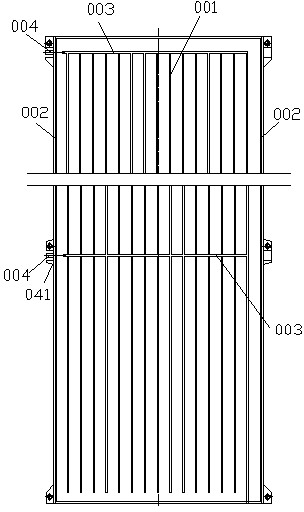

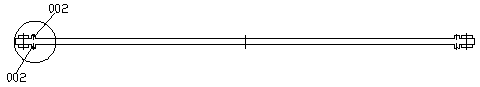

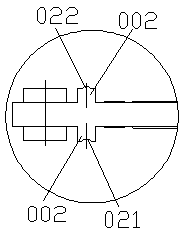

[0016] The support plate for the flat membrane element includes a plastic thin plate with alternate longitudinal diversion grooves 001 on the front and back sides. The support plate is symmetrically provided with vertical strip-shaped bosses 002 on the front and back sides along the longitudinal edge, and the bosses 002 on the front and back sides are provided with There are grooves 021 or flanges 022 that can be matched with each other, and there are two horizontal diversion grooves 003 from the width to the outermost longitudinal diversion groove 001 in the longitudinal middle area on both sides of the support plate, and the water nozzle connecting the transverse diversion groove 003 004. The vertical strip bosses 002 on both sides of the support plate are arranged in the same position. The height of the vertical strip bosses 002 on both sides of the support plate is 1 / 2 of the minimum distance between two adjacent pieces. The vertical strip bosses 002 on both sides of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com