Device for producing rubber gasket

A technology of rubber gasket and driving device, applied in metal processing and other directions, can solve the problem of incapability of mass production, and achieve the effects of convenient operation, high speed and strong practicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

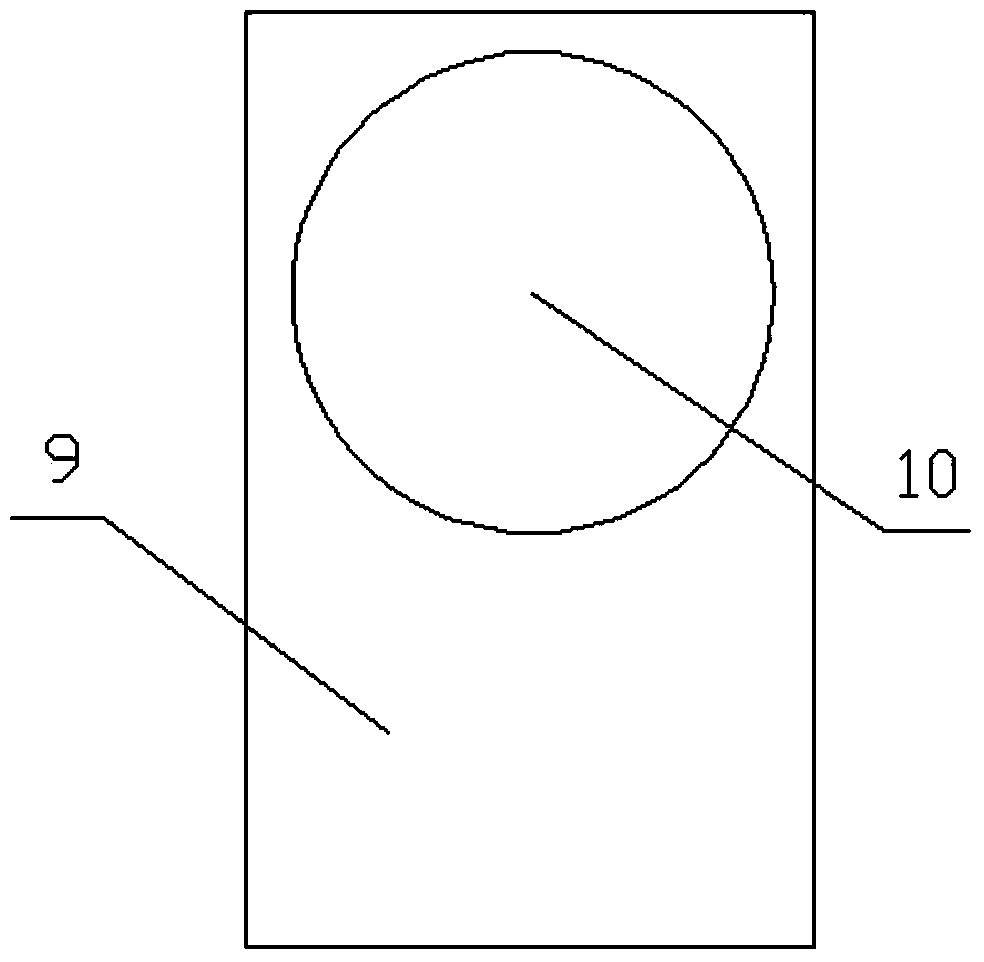

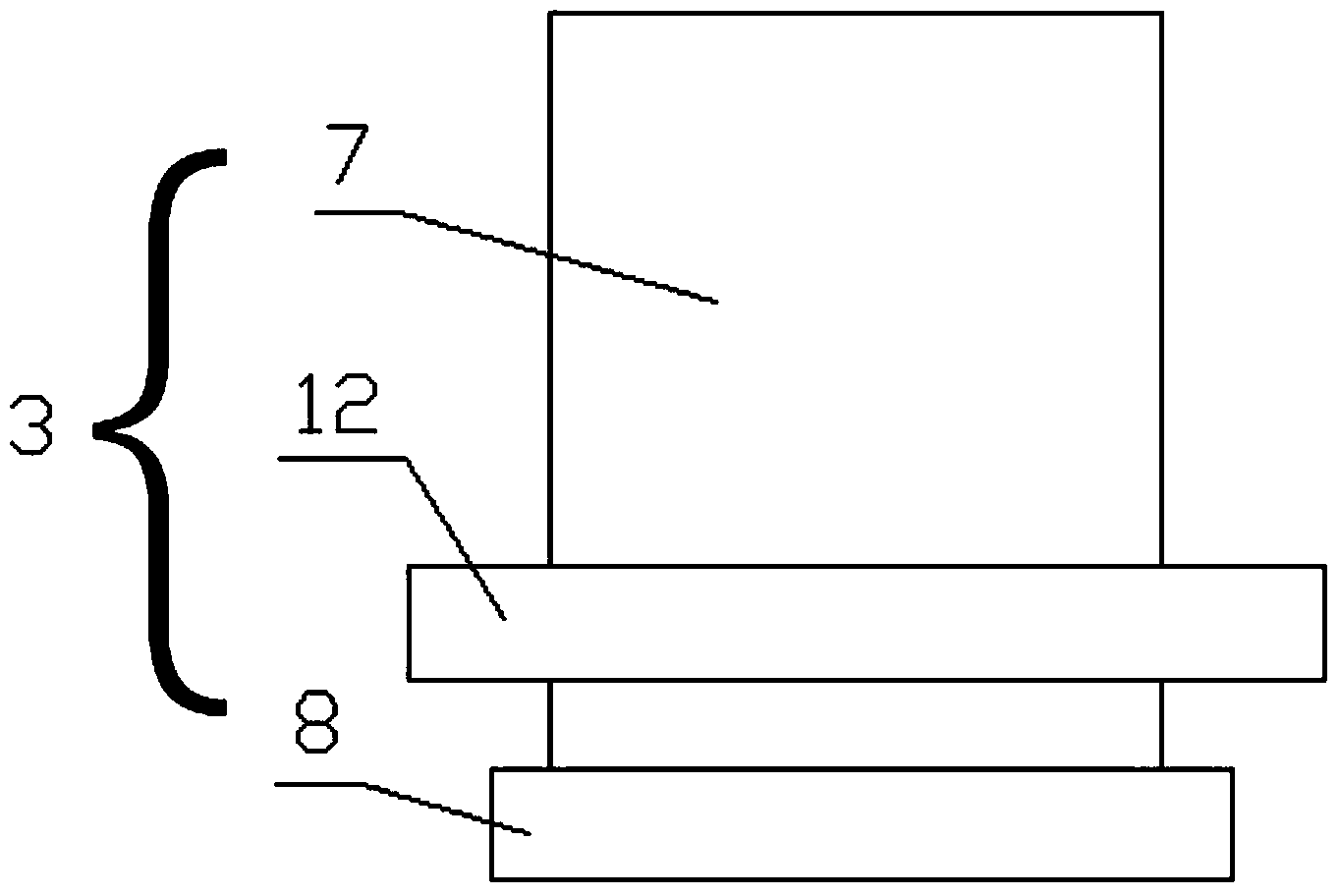

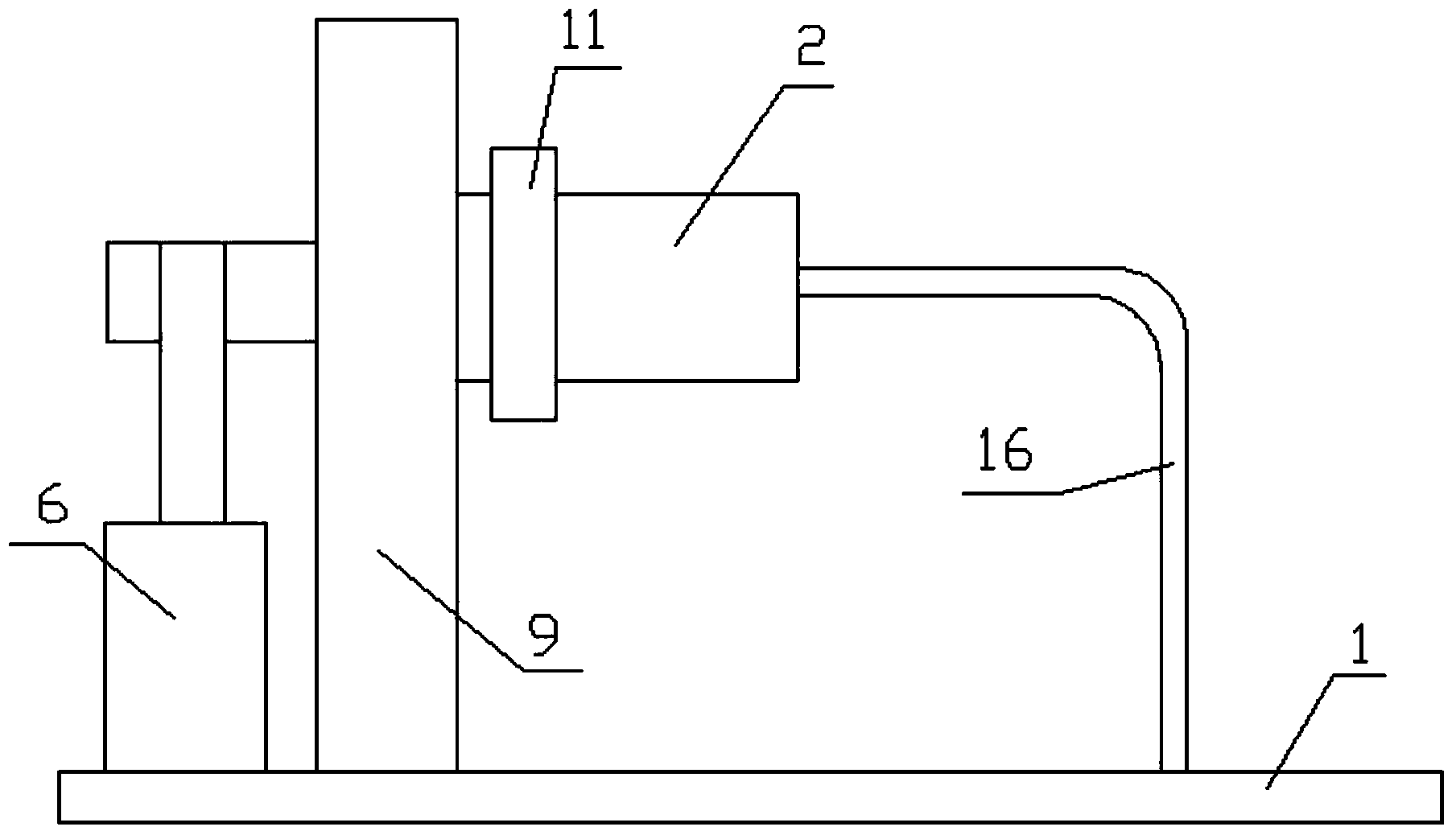

[0029] Combine figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 : A device for producing rubber gaskets, involving rubber gaskets 17, including worktable 1, fixed shaft 2, discharge ring 3, cylinder 4, cutting knife 5, driving device 6, baffle 9, connecting rod 13, sliding block 14 , The chute 15, the "7" type receiving rod 16, the fixed shaft 2, the cylinder 4 are all set on the worktable 1, the driving device 6 is drivingly connected with one end of the fixed shaft 2, and the discharge ring 3 includes an annular cylinder 7, The outer side of one end of the ring cylinder 7 is provided with a first flange 8. The inner diameter of the ring cylinder 7 is not less than the diameter of the fixed shaft 2, the outer diameter of the ring cylinder 7 is not greater than the inner diameter of the rubber gasket 17, the cutting knife 5 and the cylinder 4 The output end is connected, and the cutting knife 5 is placed on one side of the fixed shaft 2.

[0030] Put the vulcanized cylindr...

Embodiment 2

[0042] Combine figure 1 , figure 2 , image 3 , Figure 4 , Image 6 : A device for producing rubber gaskets, involving rubber gaskets 17, including worktables 1, 2 fixed shafts 2, 2 discharge rings 3, 2 cylinders 4, 2 cutting knives 5, driving device 6, baffle 9 , Connecting rod 13, sliding block 14, sliding groove 15, "7" type receiving rod 16, fixed shaft 2 and air cylinder 4 are both set on the worktable 1, and the driving device 6 is connected to one end of the fixed shaft 2 for discharging. The ring 3 includes an annular cylinder 7. The outer side of one end of the annular cylinder 7 is provided with a first flange 8. The inner diameter of the annular cylinder 7 is not less than the diameter of the fixed shaft 2, and the outer diameter of the annular cylinder 7 is not greater than that of the rubber gasket 17. Inside diameter, the cutting knife 5 is connected to the output end of the air cylinder 4, and the cutting knife 5 is placed on one side of the fixed shaft 2.

[004...

Embodiment 3

[0056] Combine figure 1 , figure 2 , image 3 , Figure 4 , Figure 7 , Figure 8 : A device for producing rubber gaskets, involving rubber gasket 17, including worktable 1, fixed shaft 2, discharge ring 3, cylinder 4, 6 cutting knives 5, driving device 6, baffle 9, "7" type connection The feed rod 16, the fixed shaft 2, and the air cylinder 4 are all set on the worktable 1. The drive device 6 is in transmission connection with one end of the fixed shaft 2. The discharge ring 3 includes an annular cylinder 7, and the outer side of one end of the annular cylinder 7 is provided with a A flange 8, the inner diameter of the annular cylinder 7 is not less than the diameter of the fixed shaft 2, the outer diameter of the annular cylinder 7 is not greater than the inner diameter of the rubber gasket 17, the cutting knife 5 is connected with the output end of the cylinder 4, and the cutting knife 5 is placed Fix one side of shaft 2.

[0057] Put the vulcanized cylindrical ring on the a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com