Chopper based infrared imagery heterogeneity correction method

A non-uniformity correction, infrared image technology, applied in image enhancement, image data processing, instruments, etc., can solve the problem of impossible installation of photoelectric angle measurement and positioning code disc, small size of infrared detector, automatic identification of high temperature images, background image Automatic discrimination, low temperature image automatic discrimination and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] Examples of the present invention will be described below in conjunction with the accompanying drawings. The embodiments described here are only used to illustrate and explain the present invention, and are not intended to limit the present invention.

[0032] A kind of chopper-based infrared image non-uniformity correction method of the present invention, specific implementation steps are as follows:

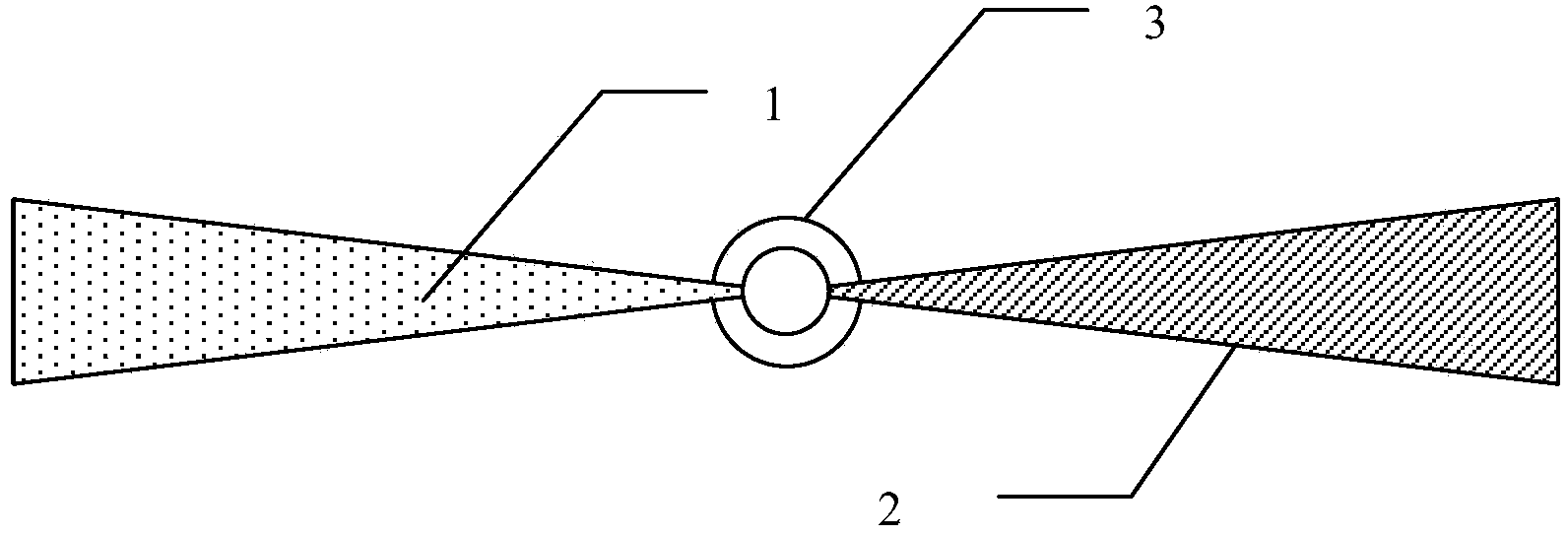

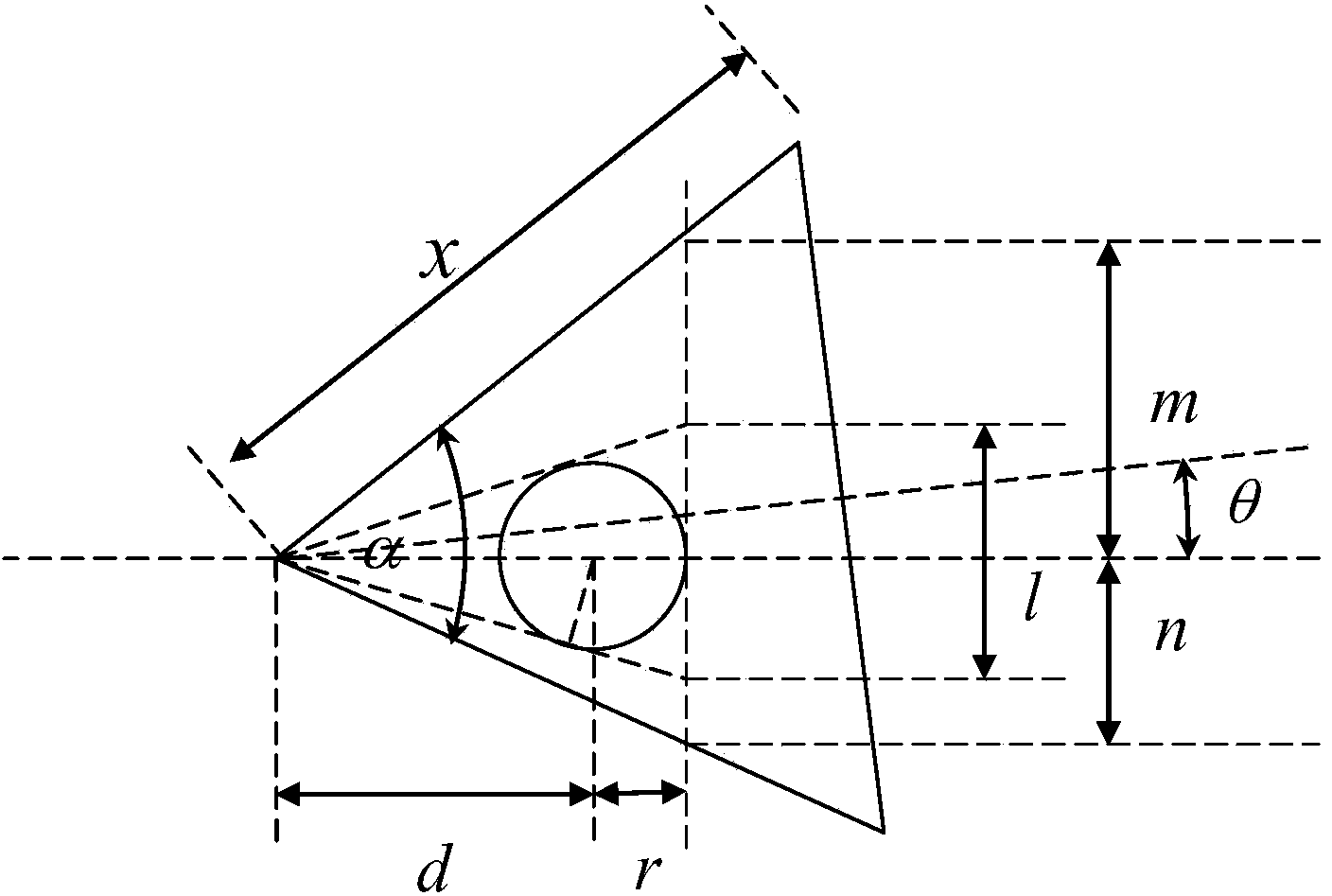

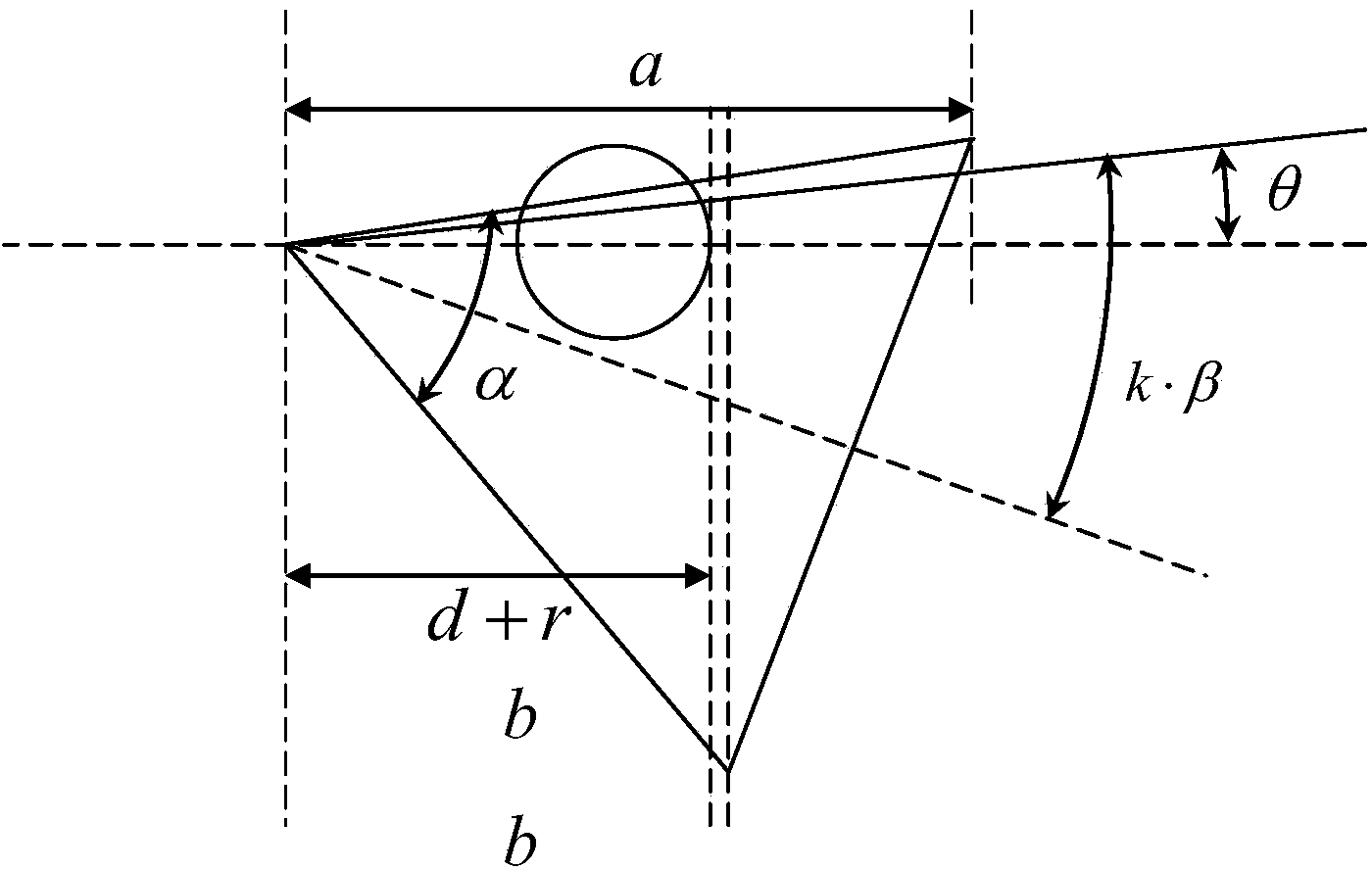

[0033] Step 1. Design the structural scheme of the chopper shielding sheet with dual temperature characteristics:

[0034] Choppers with dual temperature characteristics (see figure 1 ) mainly includes a connector 3, a gray body shielding sheet 2, and a diffuse reflection shielding sheet 1; wherein the connector 3 is connected with the gray body shielding sheet 2 and the diffuse reflection shielding sheet 1, and drives the gray body shielding sheet 2 and the diffuse reflection shielding sheet 1 to rotate , the gray body shading sheet 2 is a fan-shaped structure, the sur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com