Parallel running fault detection method for double machine sets

A technology for fault detection and operation failure, applied in the direction of motor generator testing, etc., can solve problems such as power supply failure and misjudgment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] A fault detection method in parallel operation of two sets, the specific steps are:

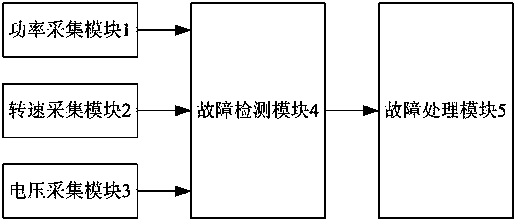

[0023] The first step is to build a fault detection system for parallel operation of two units

[0024] Fault detection system for parallel operation of two units, including: power acquisition module 1, speed acquisition module 2, voltage acquisition module 3, fault detection module 4, fault processing module 5; power acquisition module 1 is used to collect power parameters, and speed acquisition module 2 is used The parameters of the acquisition speed and the voltage acquisition module 3 are used to acquire the parameters of the voltage. The three modules are respectively connected to the fault detection module 4 with wires. The fault detection module 4 is used to detect whether there is a faulty unit and locate the faulty unit. The fault detection module 4 and The fault processing module 5 is connected by wires, and the fault processing module 5 is used to execute the processing sign...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com