Offshore oil well acidizing flowback fluid treatment process and treatment device

A technology for oil well acidification and offshore oilfields, which is applied in the direction of grease/oily substance/suspton removal devices, mining wastewater treatment, water/sewage multi-stage treatment, etc., and can solve the problem of thickening of the emulsified layer and yellowing of oily sewage at the outlet of the water phase , increased mud content, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

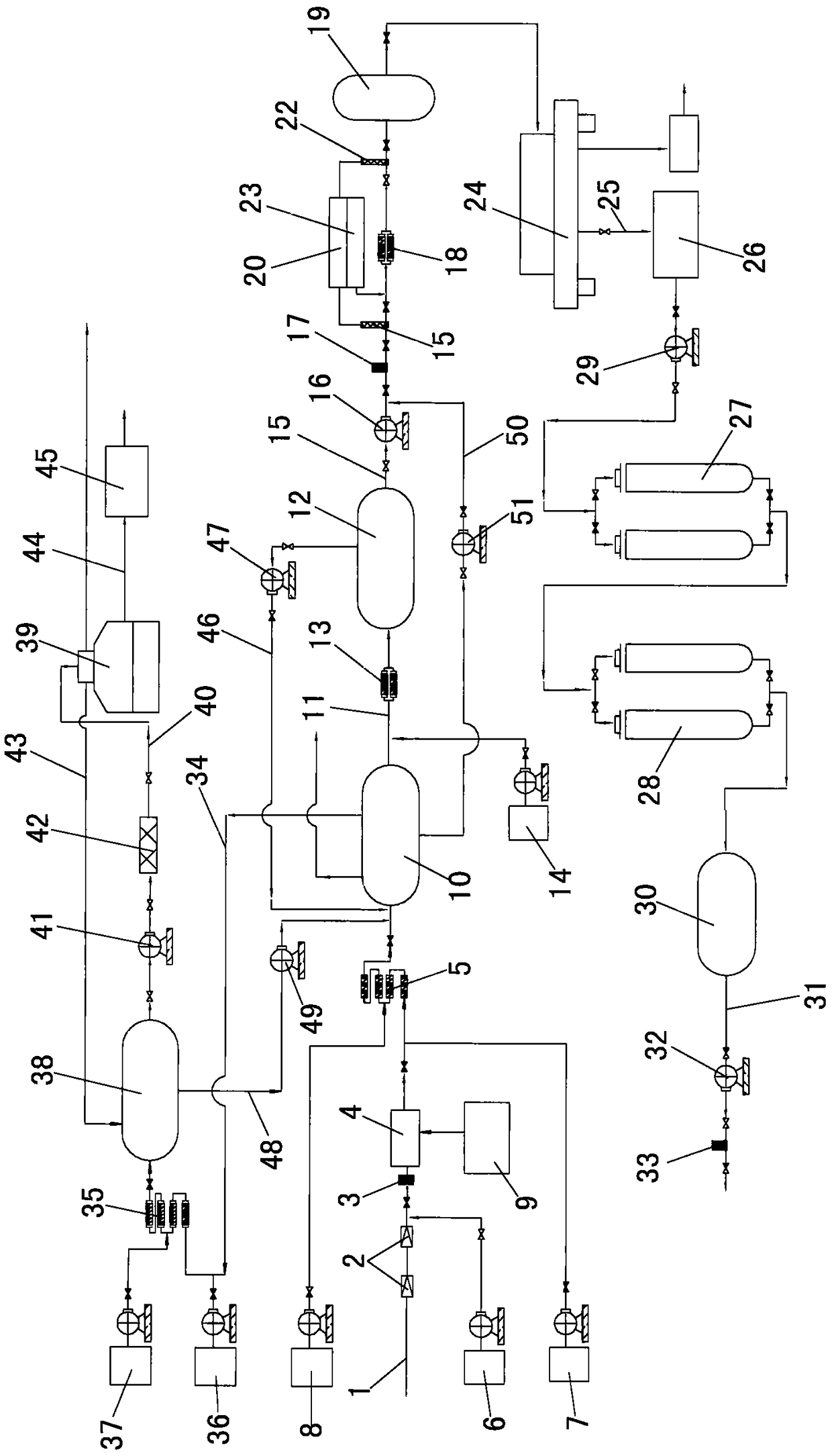

[0022] combine figure 1As shown, the offshore oil well acidizing flowback liquid treatment device of the present invention includes a liquid inlet manifold 1, and two pressure reducing valves 2, a first flow meter 3, and a heat exchanger 4 are arranged on the liquid inlet manifold 1 from front to back And the first pipeline mixer 5, the part between the pressure reducing valve 2 and the first flow meter 3 on the inlet manifold 1 communicates with the corrosion inhibitor dosing device 6 through the pipeline, and the corrosion inhibitor dosing device 6 A corrosion inhibitor is placed in the inlet manifold 1, and the part between the heat exchanger 4 and the first pipeline mixer 5 on the inlet manifold 1 communicates with the demulsifier dosing device 7 and the reverse phase demulsifier dosing device 8 through the pipeline, Wherein, a demulsifier is placed in the demulsifier dosing device 7 , and a reverse phase demulsifier is placed in the reverse phase demulsifier dosing device...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com