seat switch device

A switch device, contact switch technology, applied in electrical switches, electrical components, circuits, etc., can solve the problems of increased detection error, damage to deformation ease, and increased error of detection pressure, so as to improve responsiveness and accuracy. , the overall compact effect of the device

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

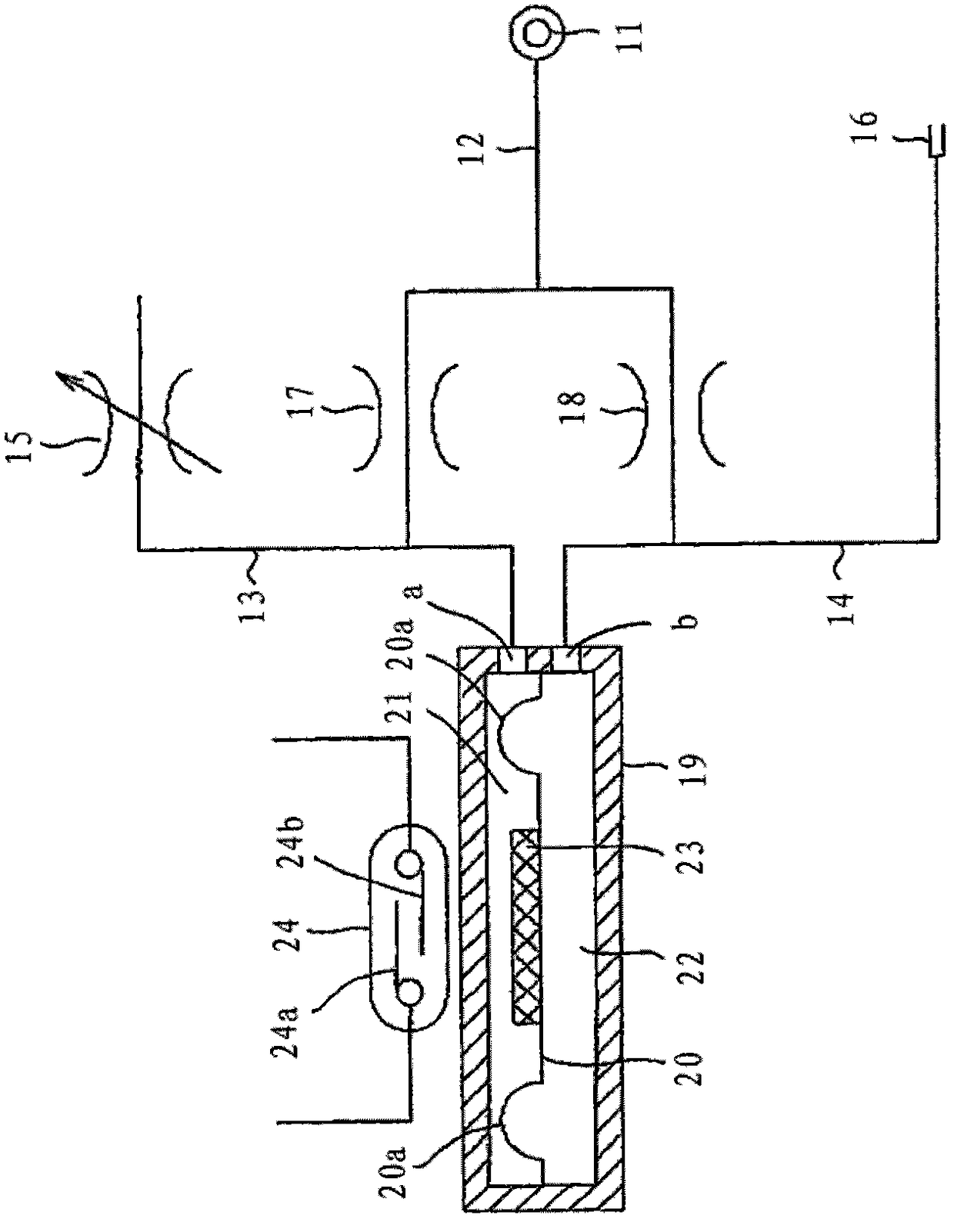

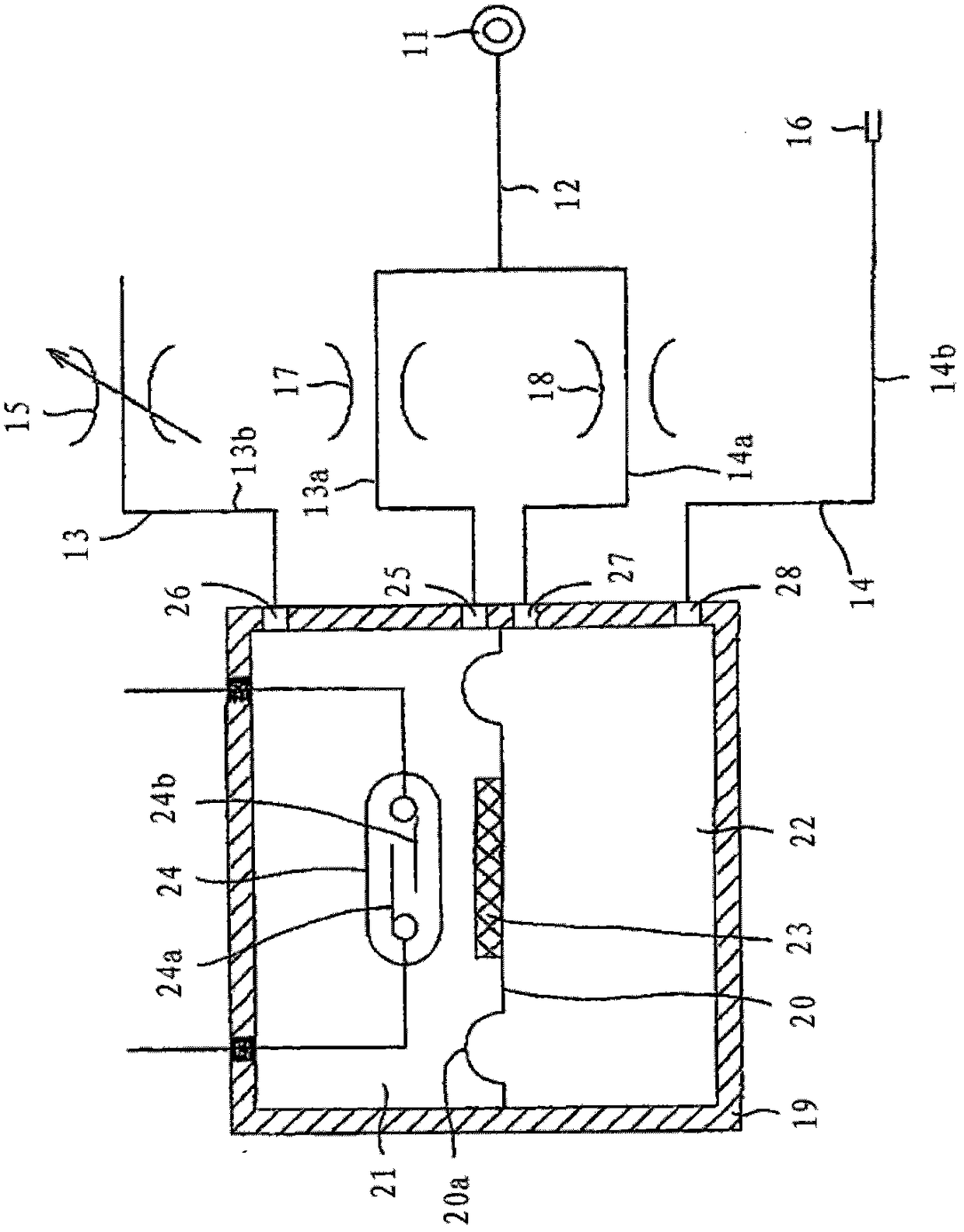

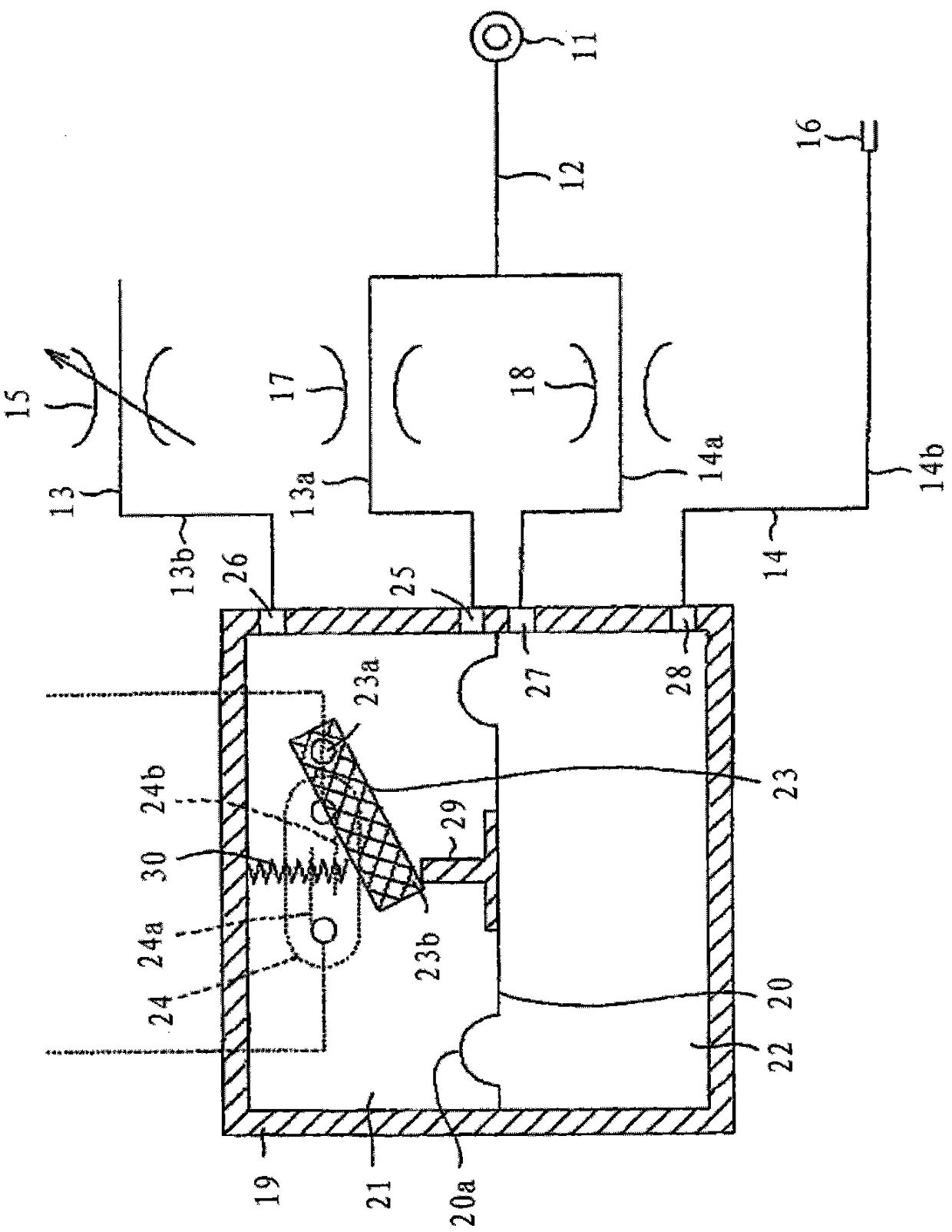

[0048] exist figure 1 In the illustrated first embodiment, the set pressure side passage 13 and the detection side passage 14 are connected in parallel to the pressure source 11 including a compressor or the like via the supply passage 12 . Furthermore, a set pressure regulator 15 comprising a variable orifice is connected to the set pressure side passage 13 , and a detection nozzle 16 is provided in the detection side passage 14 .

[0049] In addition, reference numeral 17 in the figure is an orifice provided in the set pressure side passage 13 , and 18 is an orifice provided in the detection side passage 14 .

[0050]On the other hand, a diaphragm 20 , which is a membrane member of the present invention, is installed in a case 19 that introduces the pressures of the set pressure side passage 13 and the detection side passage 14 , and the inside of the case 19 is divided into pressure chambers 21 and 22 . In addition, the mark 20a in a drawing is the fold part provided in t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com