Liquid recycling bin

A liquid recovery and box technology, which is applied in cleaning equipment, household appliances, applications, etc., can solve the problems of limiting the use range of hard surface liquid recovery devices, and achieve the effect of improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

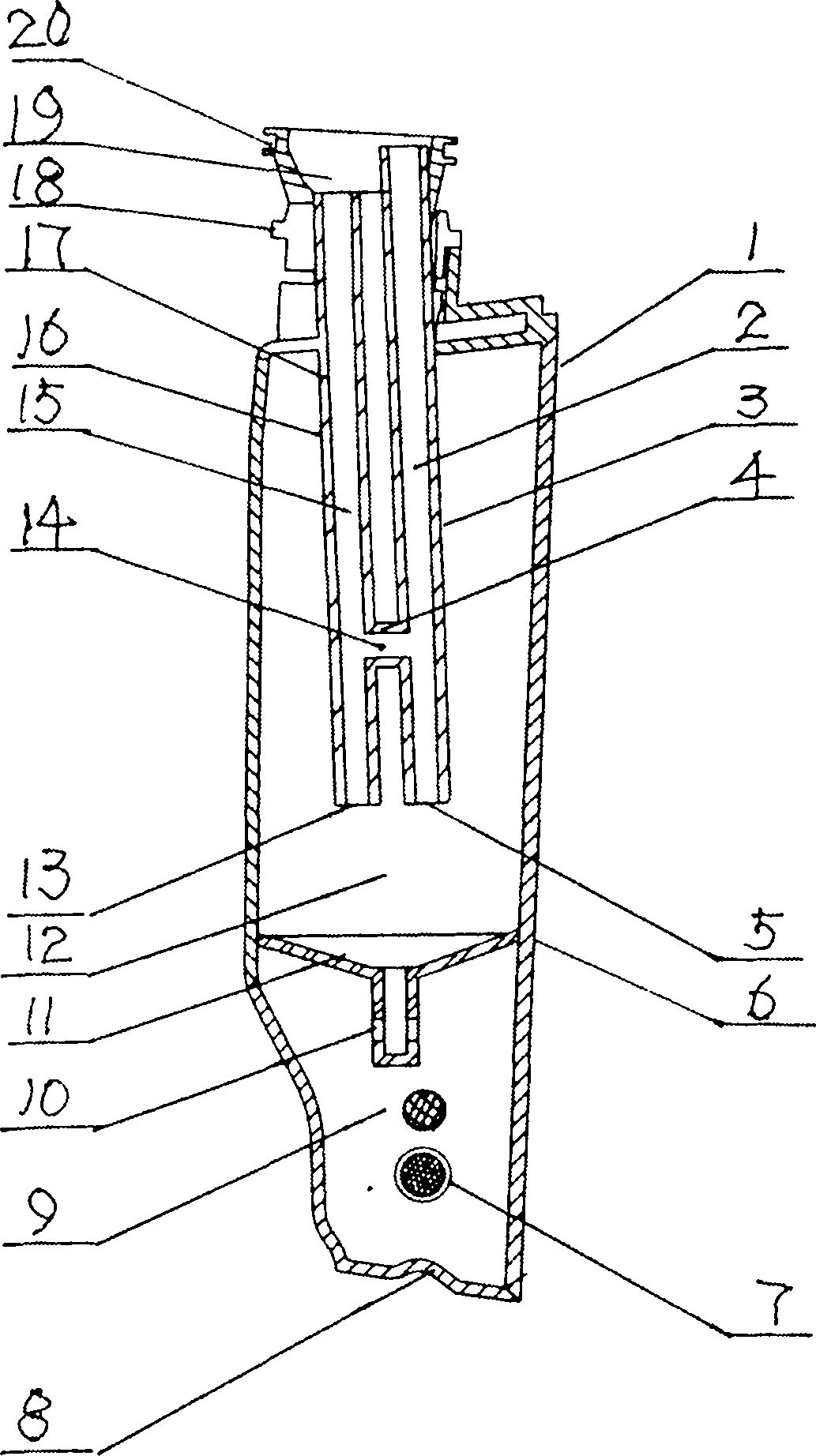

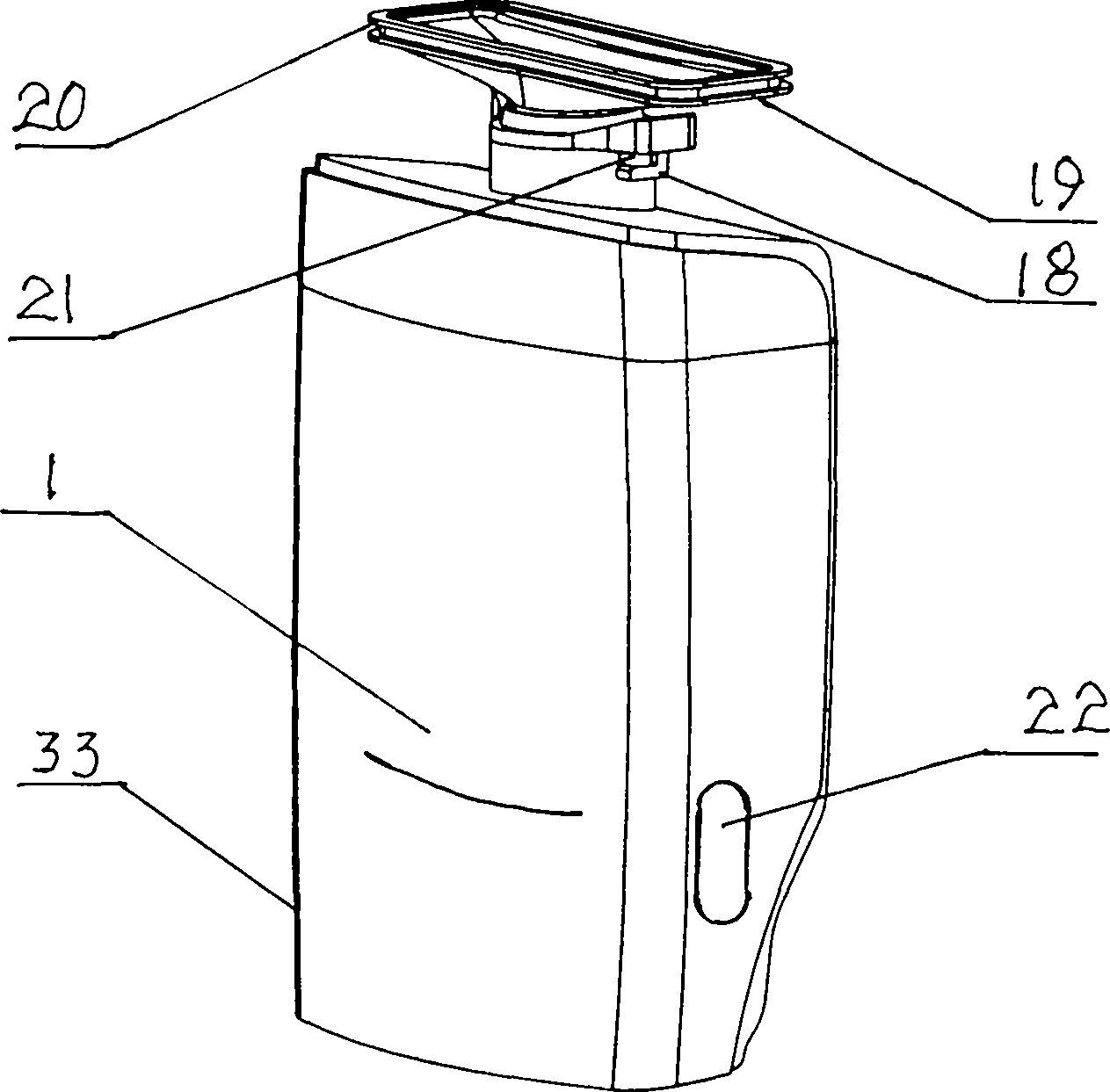

[0017] see figure 1 , figure 2 , image 3 and Figure 4 A kind of liquid recovery box 1, described liquid recovery box 1 is made up of diversion device 17, casing 33 and water storage area funnel 11; The water collecting port fixing ring 18 on the body 33 is rotated and clamped, and the water storage area funnel 11 is installed in the middle and lower part of the liquid recovery tank 1, thereby forming a water storage area 9 between the water storage area funnel 11 and the bottom of the liquid recovery tank 1.

[0018] -The diverter device 11 is a double straight pipe with a water collecting port 19 at one end and a horizontally connecting conduit 4 in the middle. Stoma13.

[0019] - The water leakage hole 10 of the funnel 11 in the water storage area is in the shape of a straight cylinder with a side wall drainage vent.

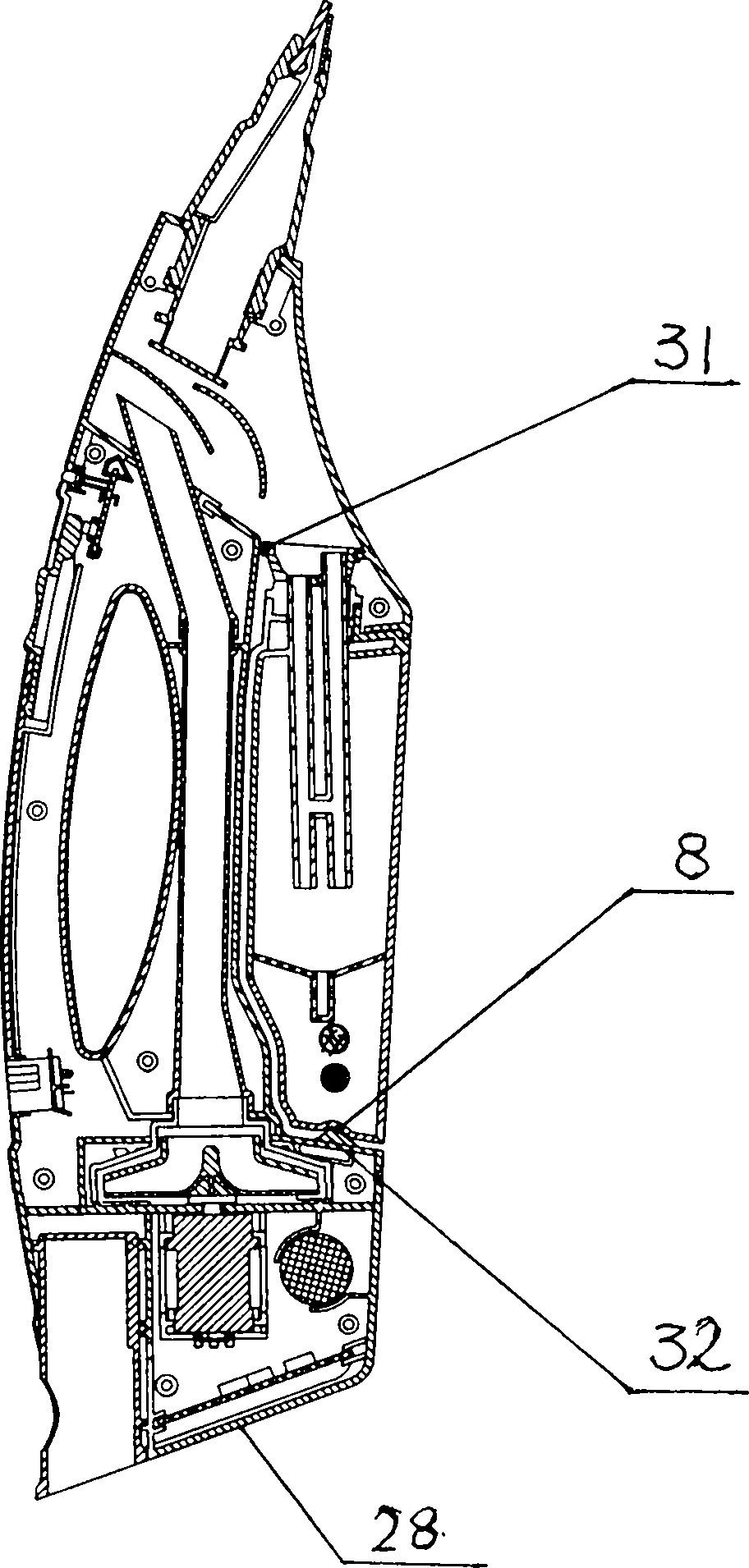

[0020] see image 3 The liquid recovery box 1 is fixedly connected with the water-collection clamp position 31 on the multi-purpose liquid recovery d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com