Product fixing and welding jig

A technology for welding fixtures and products, applied in welding equipment, auxiliary welding equipment, welding/cutting auxiliary equipment, etc., can solve the problems of easy loosening and incomplete fixation, and achieve the effect of not easy loosening, simple structure and accurate positioning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] Specific embodiments of the present invention will be further described in detail below.

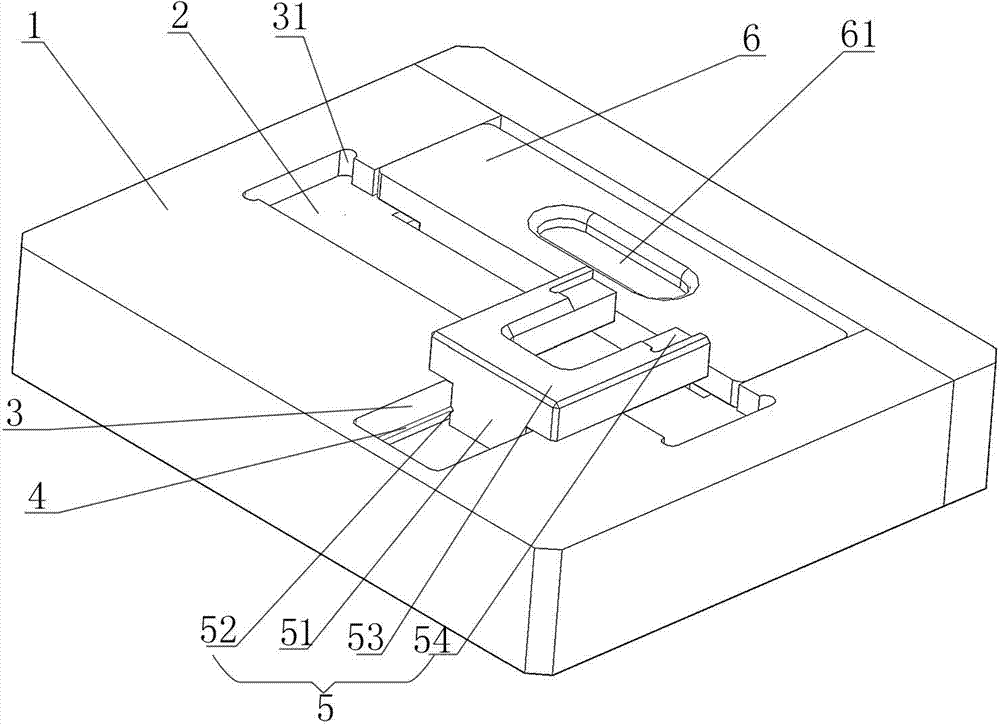

[0014] like figure 1 As shown, the product fixed welding jig of the present invention includes a jig main body 1, the jig main body 1 is a rectangular block, and the top surface of the jig main body 1 is provided with a strip-shaped second bar for placing the main body of the weldment. A groove 2, the four corners of the first groove 2 are respectively provided with semicircular notches 31, the first groove 2 side is provided with the second groove 3 perpendicular to the first groove 2, the second groove 3 two Slide rails 4 are respectively provided on the sides, and a sliding positioning fixture 5 is connected to the second groove 3 through the slide rails 4 .

[0015] The lower part of the sliding positioning fixture 5 includes a connecting block 51, the two sides of the connecting block 51 are provided with chute 52 corresponding to the slide rail 4, the sliding positioning fi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com