Wheat fine single-grain seeder suitable for individual development experiment

A kind of seeder and wheat technology, which is applied in the direction of single-seed seeder, seeder parts, interval quantitative sowing machinery, etc., can solve the problem that single-seed sowing cannot be effectively realized, and achieve the effect of ensuring the accuracy of single-seed sowing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0046] Embodiment 1: A sowing machine for fine single-grain sowing of wheat, suitable for the sowing process of wheat ontogeny experiments. The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

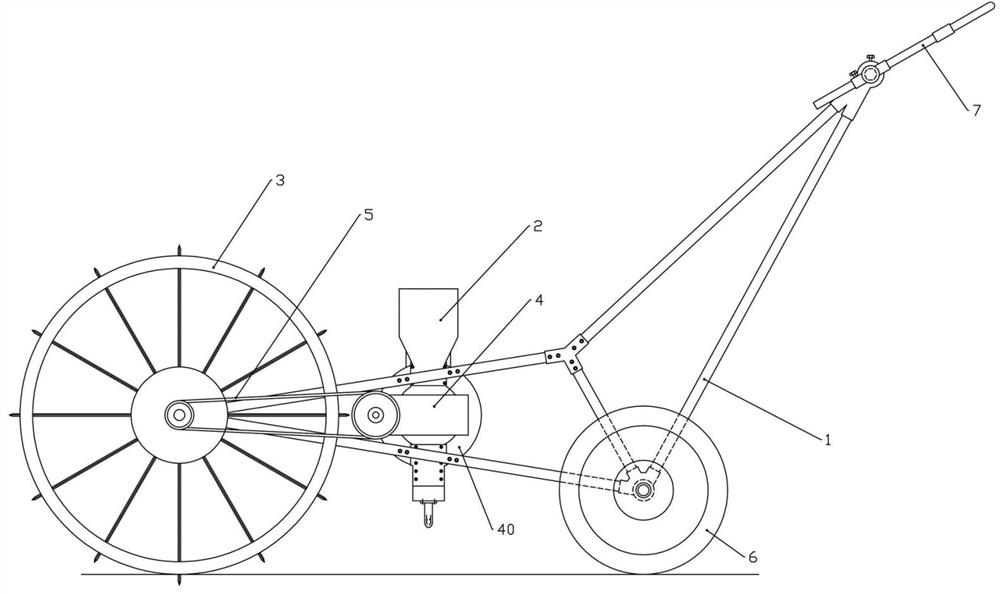

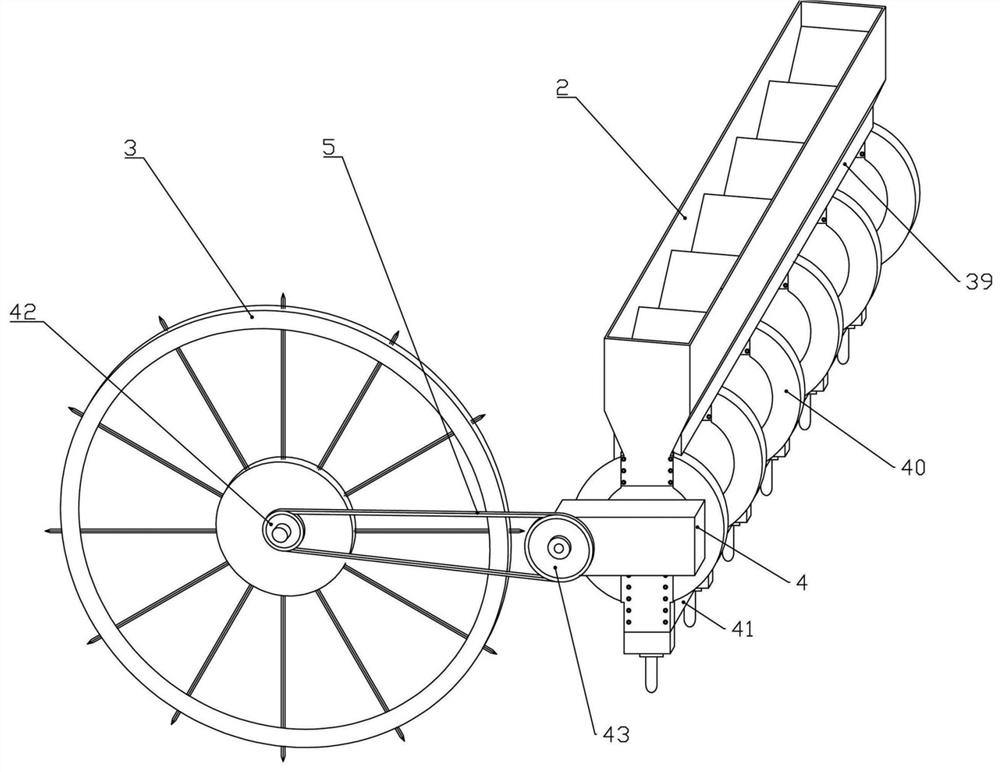

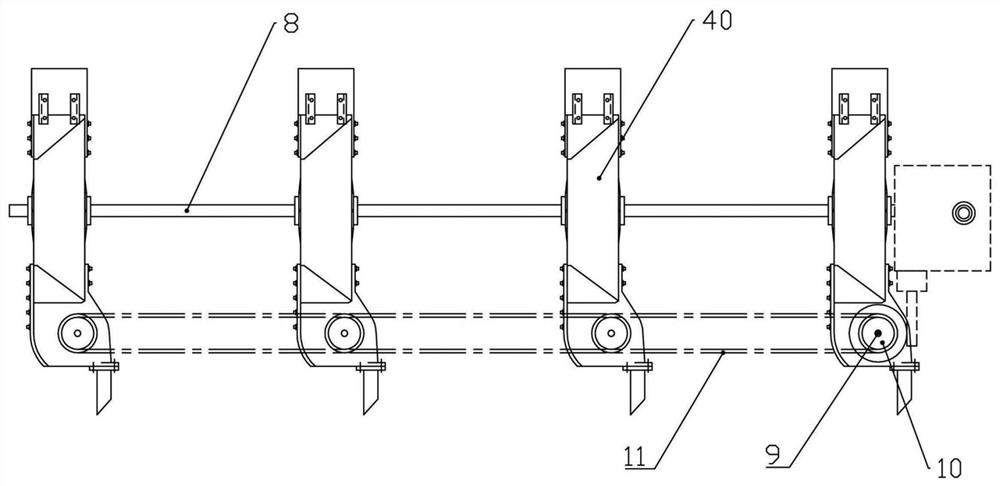

[0047] The seeder can be used as figure 1 As shown in the structure, it can be seen from the figure that the front side of the bracket extends forward and is provided with a front bushing, and a pair of ground wheels are installed, and the rear end of the bracket extends downwards, and a rear bushing is provided, and a pair of ground wheels are installed. follower wheel. A handle is installed on the upper part of the rear end of the support, and the seeder can be pushed to move forward after the handle is pushed. There are ground teeth on the periphery of the ground wheel. When the ground wheel walks along the trench (ditching in advance), the seeder is driven to work by the power output from the ground wheel and the tra...

Embodiment 2

[0064] Embodiment 2: On the basis of the implementation of Embodiment 1, an additional transmission can also be added to any output shaft of the gearbox, such as output shaft 1 or output shaft 2, or the gearbox or the corresponding transmission can be set to an adjustable speed ratio Speed change mechanism, this kind of speed change mechanism is often operated by humans to achieve output speed change adjustment. When the frustum turntable 17 is designed with wear-resistant transparent materials (or the observation window is partially installed on the frustum turntable 17 and a transparent wear-resistant layer is installed), the rotation of the frustum turntable 18 inside the frustum turntable 18 and the surplus quantity of material distribution can be observed through perspective , in order to manually adjust the speed ratio of each speed change mechanism.

Embodiment 3

[0065] Embodiment 3: On the basis of Embodiment 2, the gearbox or the extra transmission is changed into an automatic transmission mechanism, and is controlled by the controller, and a sensor for detecting the excess amount of the distribution is set in the area of the distribution mechanism of the conical frustum body, For example, a laser sensor probe or a contact sensor element is added to a certain section of the cone shell to continuously monitor the quantity of wheat grains lying on the sides in each passing trough. Sensors for detecting the accumulation of wheat grains can also be set in the distributor area, for example, a laser sensor probe or a contact sensing element is added in the inclined channel 46 to continuously monitor the number of lying wheat grains in each passing trough. .

[0066] The controller performs automatic speed change control on the corresponding speed change mechanism according to the corresponding detection data, or reminds people to perform...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com