Adaptive automatic sand mill

A sand mill, self-adaptive technology, applied in the field of sand mills, can solve the problems of inconsistent size, low production efficiency, and harm to workers' health.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 Embodiment

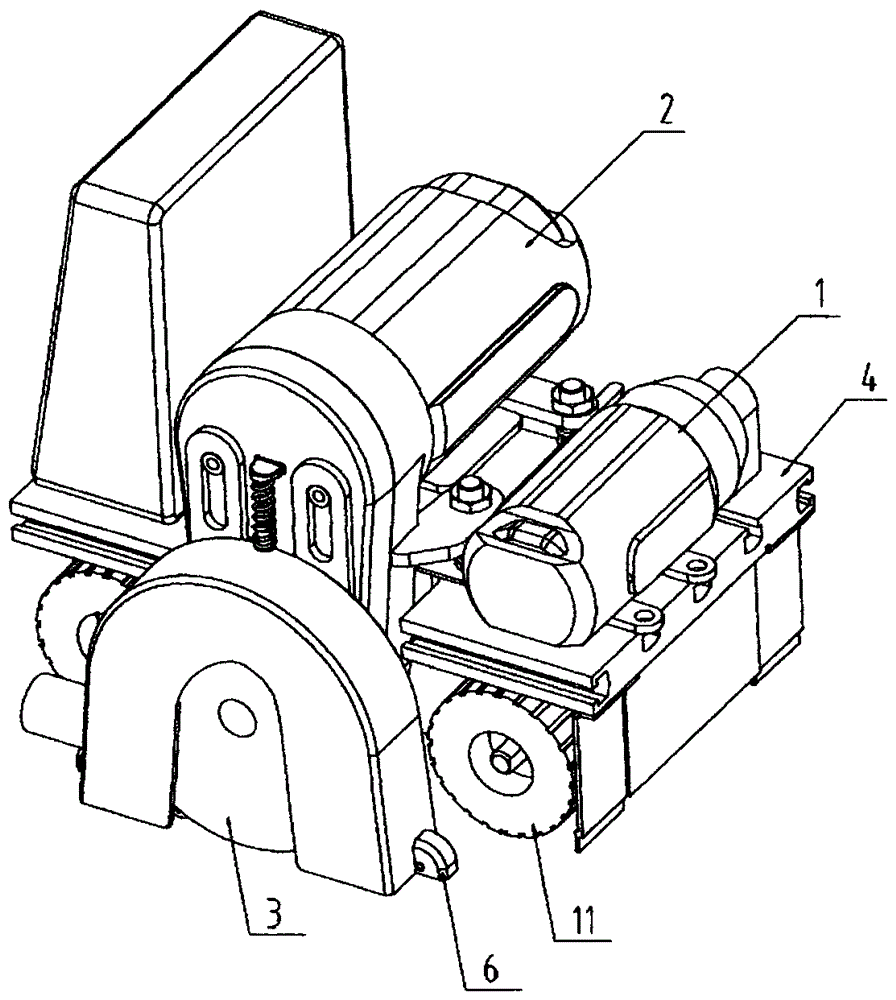

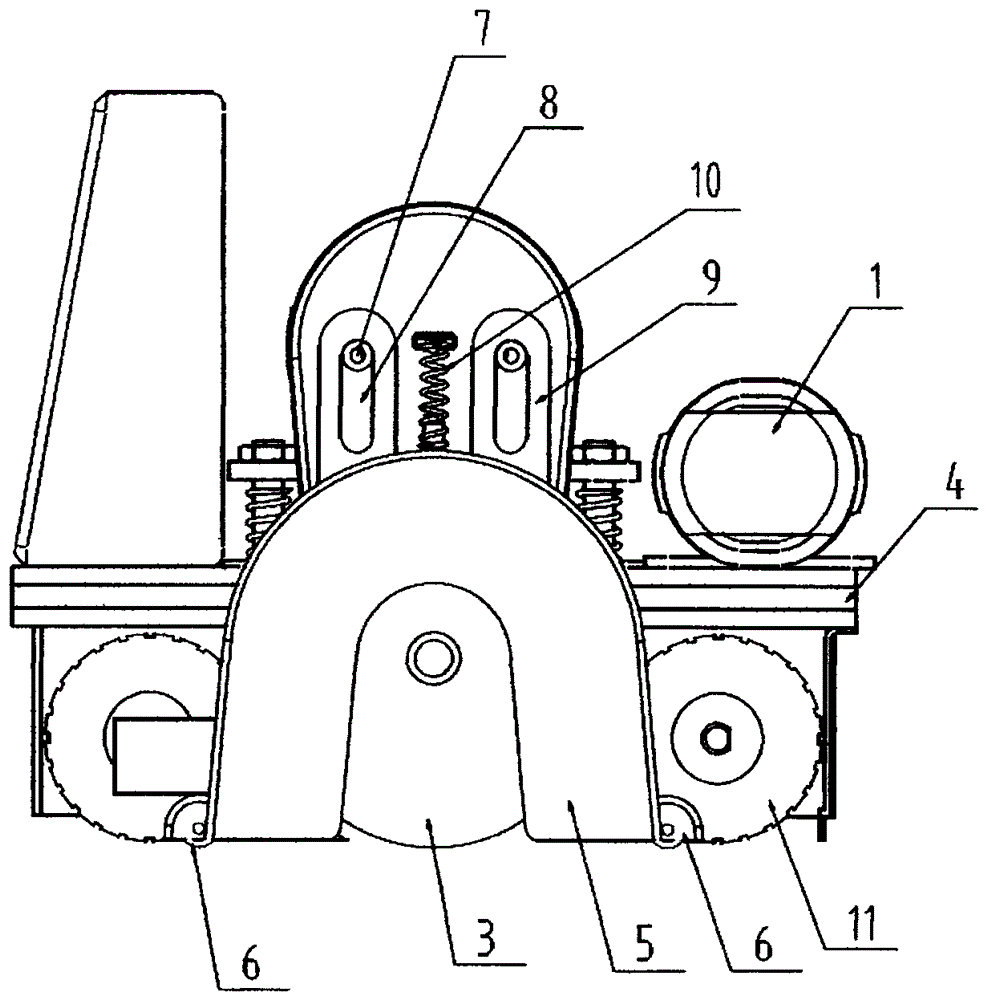

[0022] Such as figure 1 As shown, the self-adaptive automatic sand mill of the present invention includes a vehicle-mounted platform 4, a sanding system and a walking system arranged on the vehicle-mounted platform 4, and the walking system includes a 4 above the driving motor 1 and the wheels 11 arranged under the vehicle-mounted platform 4 driven by the driving motor 1 . The sanding system at least includes a sanding motor 2 and a grinding wheel 3, and the grinding wheel 3 is driven by the sanding motor 2 to rotate and perform sanding. In this preferred embodiment, the sanding system further includes a gear transmission system for connecting the sanding motor 2 and the grinding wheel 3 to transmit driving force, and the gear transmission system and the sanding motor share a shell. Of course, the grinding wheel 3 can also be directly driven by the grinding motor 2 .

[0023] The grinding wheel 3 is provided with a grinding wheel guard assembly, which includes a grinding whe...

no. 2 Embodiment

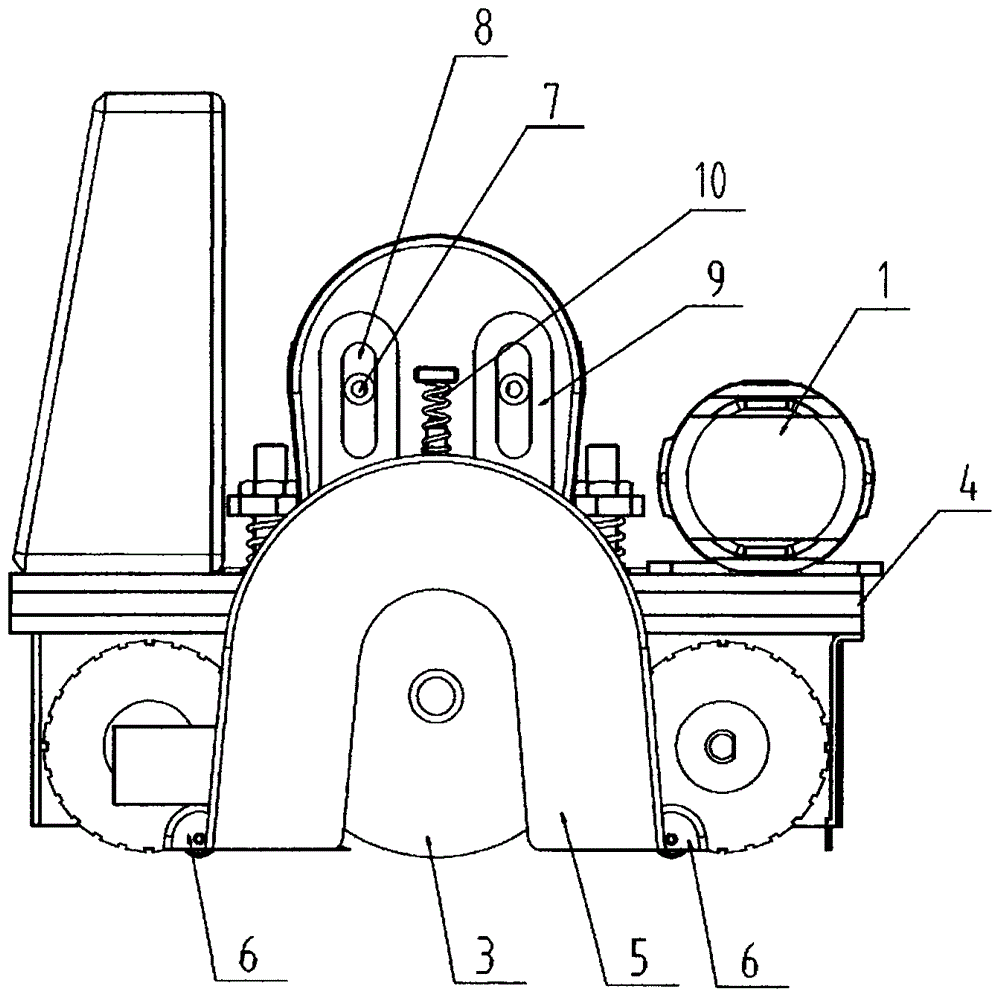

[0031] according to Figure 4 As shown, when a pulley 6 is provided at one end of the U-shaped arc profile of the grinding wheel guard 5, the grinding wheel guard 5 is pivotally arranged on the shell of the sanding motor 2 or the gear transmission system, between the two For example, a curved waist-shaped groove can be provided on the grinding wheel guard 5 to connect with the guide post on the sanding motor 2 (not shown in the figure).

[0032] When the sand mill was energized and started, the sand mill motor 2, the emery wheel guard assembly and the emery wheel moved downward as a whole, and the pulley 6 and the emery wheel 3 at the bottom of the emery wheel guard 5 contacted the surface to be sanded simultaneously. When the sand mill works for a period of time, the grinding wheel 3 is worn, the sand grinding system will continue to decline as a whole under the action of the lifting control system, and the surface to be sanded will exert a reaction force on the pulley 6, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com