Steel wire online surface treatment device

A surface treatment device and steel wire technology, applied in the direction of grinding/polishing safety devices, grinding machines, grinding machine parts, etc., can solve the problems of air pollution, water pollution, grinding debris, etc., to ensure the removal effect , Guarantee the effect of work and the effect of consistency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

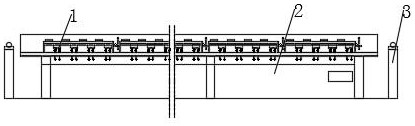

[0036] see Figure 1-5 , the present invention provides a technical solution: a steel wire online surface treatment device, including a friction removal part 1, a water washing cleaning part 2 and a wire tensioning part 3, and the friction removal part 1 includes several groups arranged along the axis of the steel wire to be processed Friction block 103, the surface of friction block 103 is provided with grooves for steel wires to penetrate along the length direction, and the back of friction block 103 is provided with a force applying mechanism that can push friction block 103 to apply constant pressure to steel wires, and the friction of different orientations outside the steel wires to be processed Blocks 103 are arranged at intervals;

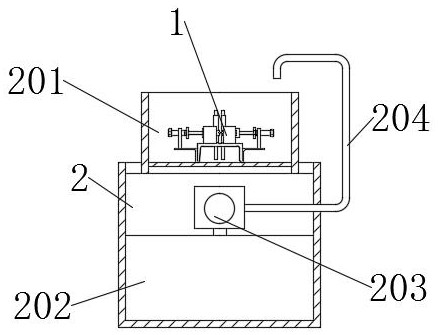

[0037] The washing and cleaning part 2 includes a circulating water flow supply mechanism capable of acting on the working position of the friction block 103;

[0038] The pay-off tension section 3 is arranged at both ends of the washing a...

Embodiment 2

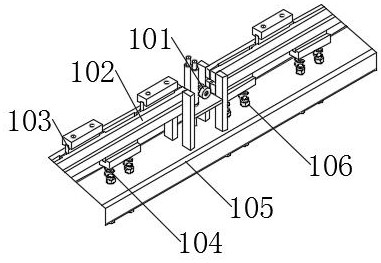

[0050] see Figure 6-8 , the present invention provides a technical solution: the sliding direction of the friction block 103 is vertical, several groups of friction blocks 103 are arranged in parallel in the transverse section of the friction removal part 1, and the guide frame 102 is divided into several sections along the steel wire feeding direction. The joint guide frame 102 is arranged with two groups of friction blocks 103 facing oppositely, and the top of the friction blocks 103 at the upper end is fixedly provided with a counterweight, and the same lower supporting plate 107 is fixed under the friction blocks 103 at the lower side in the same transverse section, and the lower A lifting plate is arranged below the supporting plate 107, an adjusting bolt 106 for adjusting the distance is arranged between the lifting plate and the base plate 105, and an elastic member 104 is arranged vertically between the lifting plate and the lower supporting plate 107;

[0051] Throug...

Embodiment 3

[0053] see Figure 9-11 , the present invention provides a technical solution: the sliding direction of the friction block 103 is horizontal, the tail end of the friction block 103 is provided with a fixing clip, the tail end of the fixing clip is provided with a guide post along the sliding direction of the friction block 103, and the outer sliding setting of the guide post is limited. Position plate, an adjusting bolt 106 for adjusting the gap is arranged between the limit plate and the guide frame 102, and an elastic member 104 is arranged outside the guide column between the limit plate and the fixing clip;

[0054] Different from the friction block 103 arranged in the vertical direction, the friction block 103 arranged horizontally is convenient to adjust the centering degree of the inner threaded steel wire, and the adjustment method on both sides is the same, and avoids the positive pressure exerted by the friction block 103 on the surface of the steel wire by its own we...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com