Machining device and machining method

A technology for equipment and workpieces, applied in metal processing equipment, grinding/polishing equipment, manufacturing tools, etc., can solve problems such as changes in pressing force at the workpiece, and achieve the effect of reducing weight, simplifying installation, and improving operating characteristics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] A preferred embodiment of the present invention is described below with reference to the accompanying drawings. Other variants mentioned in this context of specific individual features can each be individually combined with one another in order to form new embodiments.

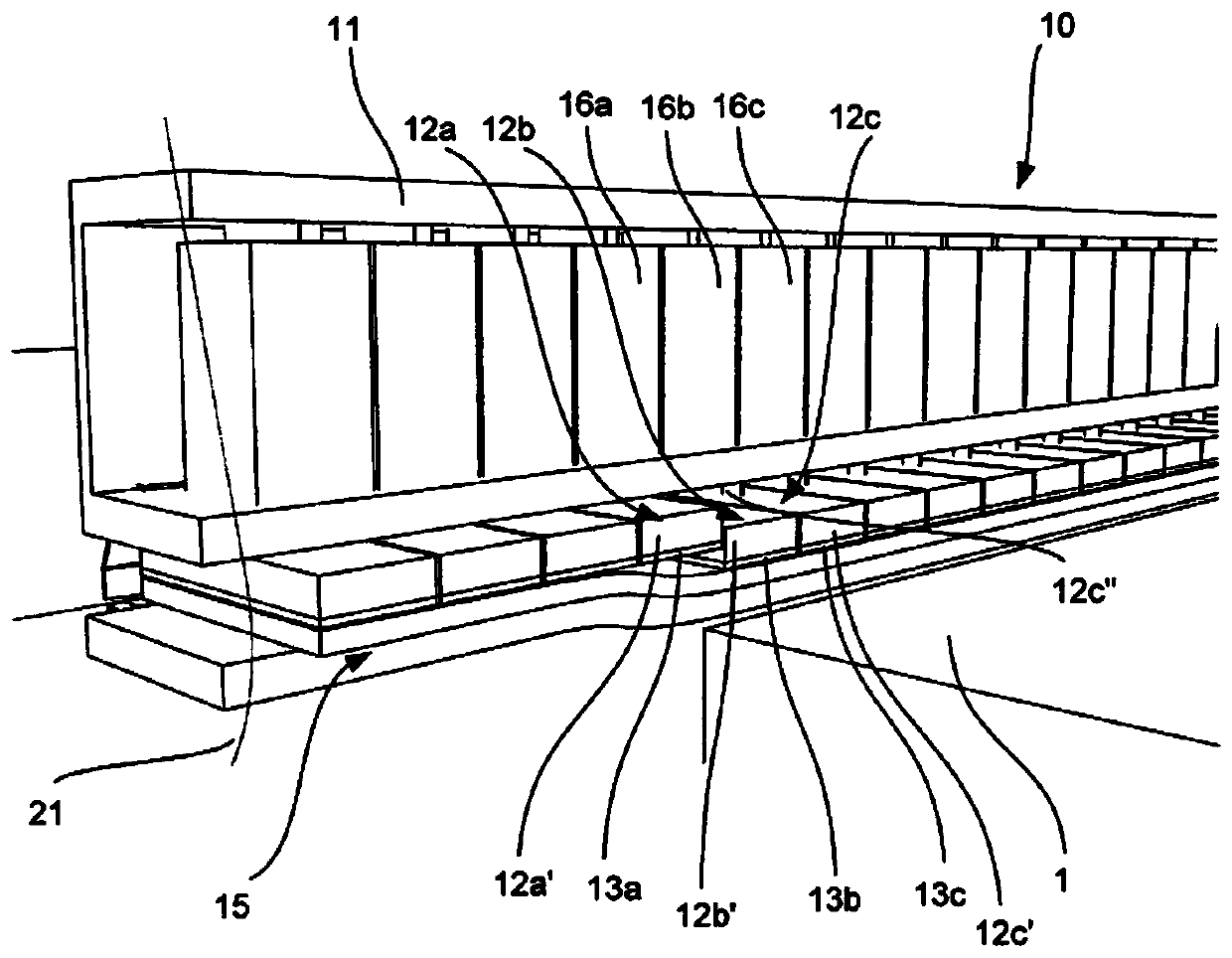

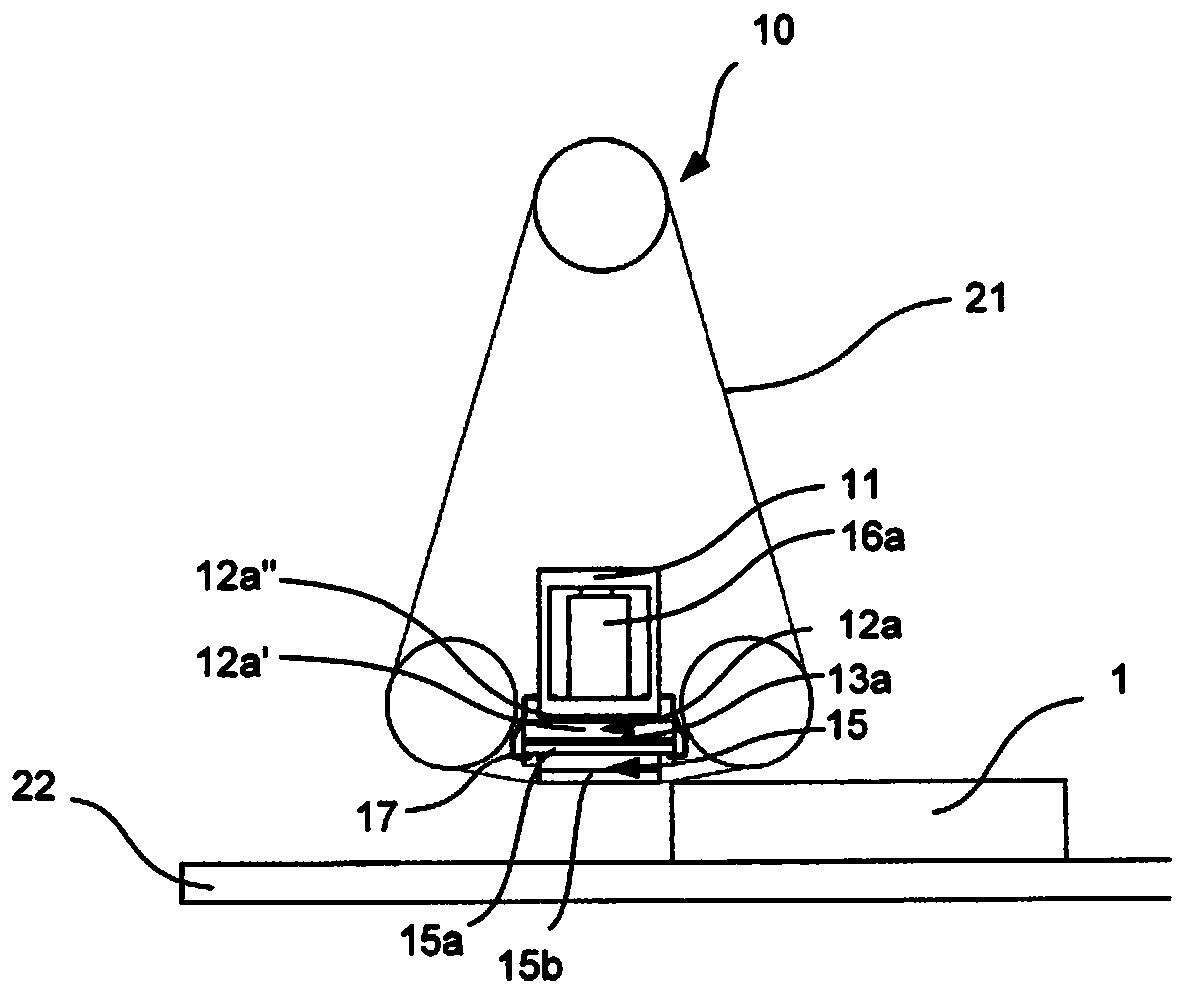

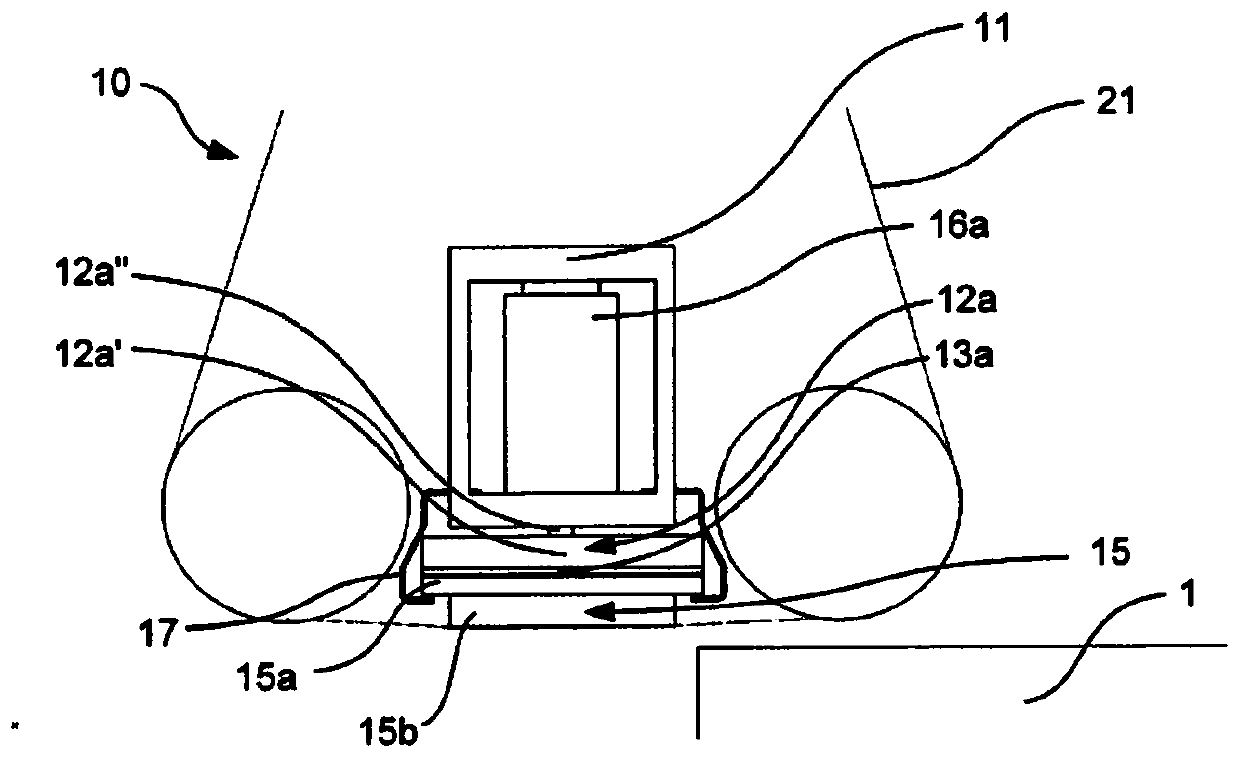

[0044] figure 1 A detailed view of the device 10 is shown, which in the embodiment explained here is a sanding unit of a wide-band sander. A perspective view of a broadband sander capable of accommodating multiple sanding units is depicted in Figure 3. It can be seen that the device 10 can also be used in a belt sander.

[0045] The device 10 comprises a carrier element 11 which is figure 1 -Extends above the machine tool not shown in detail in -2. The carrier element 11 is in the belt sander image 3 It extends within the housing shown in and transversely to the conveying path of the workpiece. In particular, the workpieces 1 can be moved by means of a preferably circumferential conveyor belt 22 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com