Novel oil drum

A new type of technology for oil drums, which is applied in the direction of containers, caps, and lids to close containers tightly. It can solve problems such as oil leakage, environmental pollution, and damage to the barrel body, and achieve improved compression resistance, convenient use, and extended service life. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

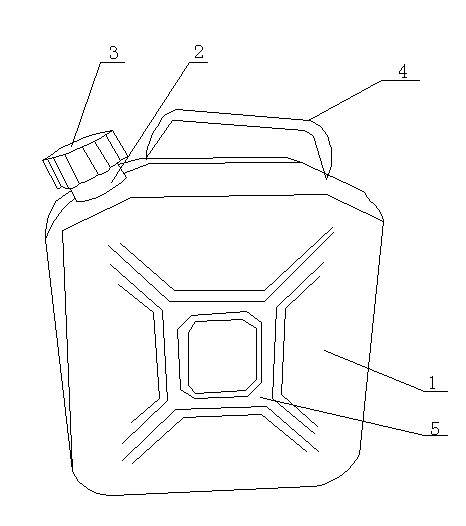

[0020] Such as figure 1 As shown, a novel oil drum includes a barrel body 1, an oil nozzle 2, an oil nozzle cover 3, and a handle 4 is arranged on the top of the barrel body 1. Barrel body 1 side wall and bottom are provided with reinforcing rib 5 respectively, and reinforcing rib 5 is formed by the polygonal shape that is sunken in the oil drum around, and the vertex of polygon is provided with the extension line sunken in the oil drum. Polygons are either squares or rectangles.

[0021] The barrel body 1 is a split structure, the barrel body 1 is composed of left and right symmetrical barrel walls, and the left and right symmetrical barrel walls are welded and connected.

[0022] The width of the barrel wall decreases successively from top to bottom.

[0023] The depth in the middle of the barrel wall is higher than the depth at both ends of the barrel wall.

[0024] The cross section of the handle 4 is V-shaped.

[0025] A protrusion is provided on the outer peripheral ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com