A hybrid vacuum pump system

A water ring vacuum pump and vacuum pump technology, applied in the field of hybrid vacuum pump systems, can solve the problems of low vacuum degree of water ring vacuum pumps, low energy consumption of mechanical vacuum pumps, and poor application, and achieve good energy saving effect and shorten Effects of working time, ease of retrofit and implementation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

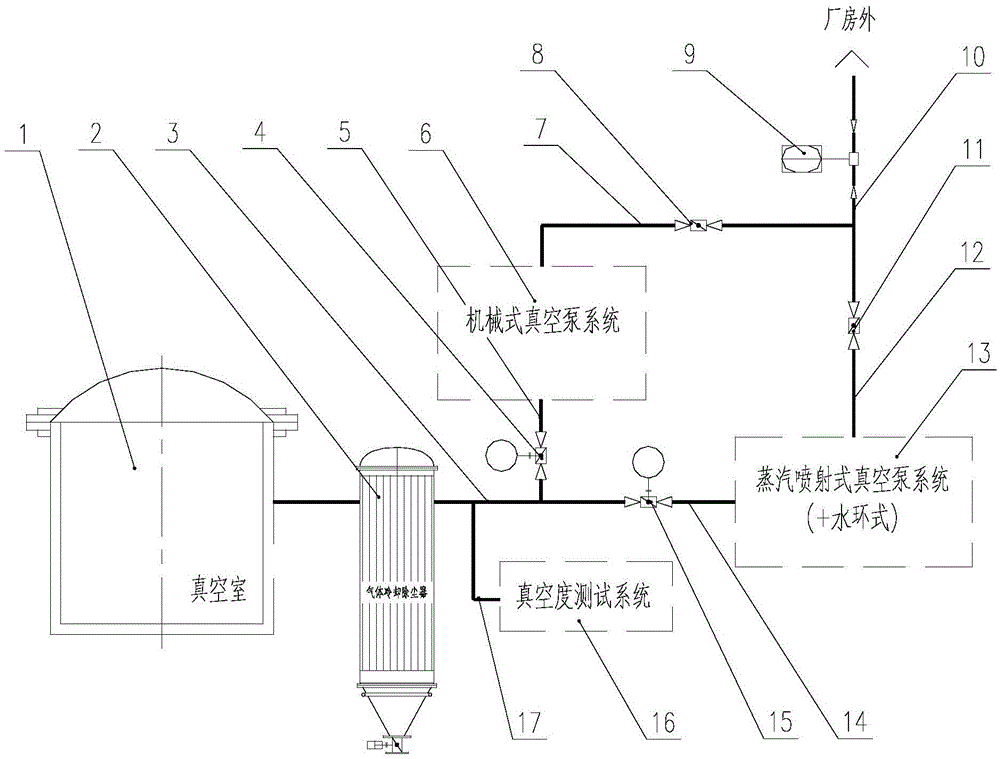

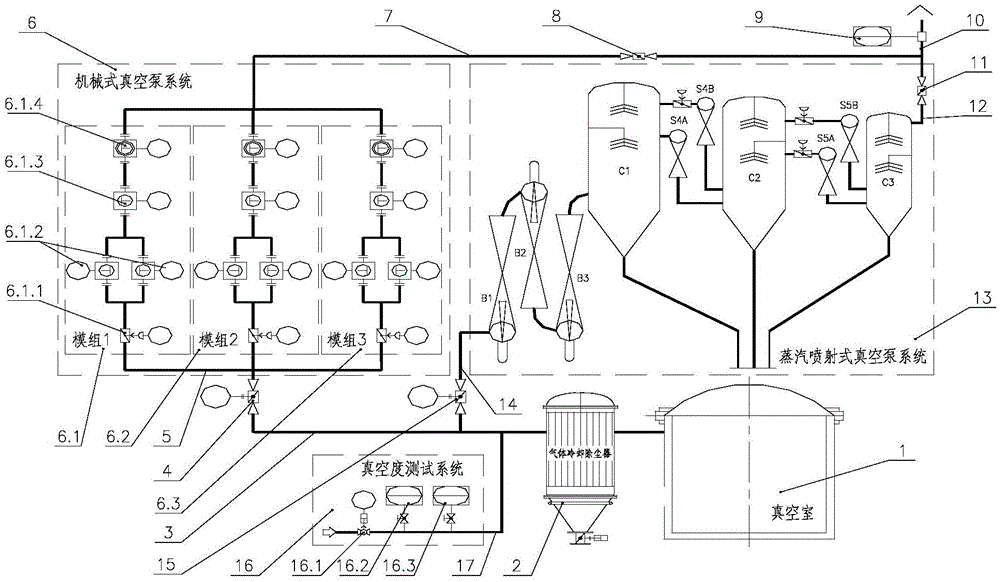

[0030] refer to figure 2 , a hybrid vacuum pump system, including a vacuum chamber 1, the vacuum chamber 1 is connected to the inlet of the gas cooling dust collector 2 through a first suction pipe 3, and the outlet of the gas cooling dust collector 2 is divided into two branches: one branch passes through the third The suction pipeline 14 is communicated with the steam jet type (+water ring type) vacuum pump system 13, and a second vacuum shut-off valve 15 is installed on this branch; the other branch is communicated with the mechanical vacuum pump system 6 through the second suction pipeline 5, A first vacuum shut-off valve 4 is installed on the branch. According to the different volume of the vacuum chamber 1 and the tonnage of the molten steel contained in the vacuum chamber 1, the pumping capacity of the steam jet vacuum pump system 13 is required to be different. In this embodiment, it is assumed that the steam jet vacuum pump system 13 is composed of five stages of ful...

Embodiment 2

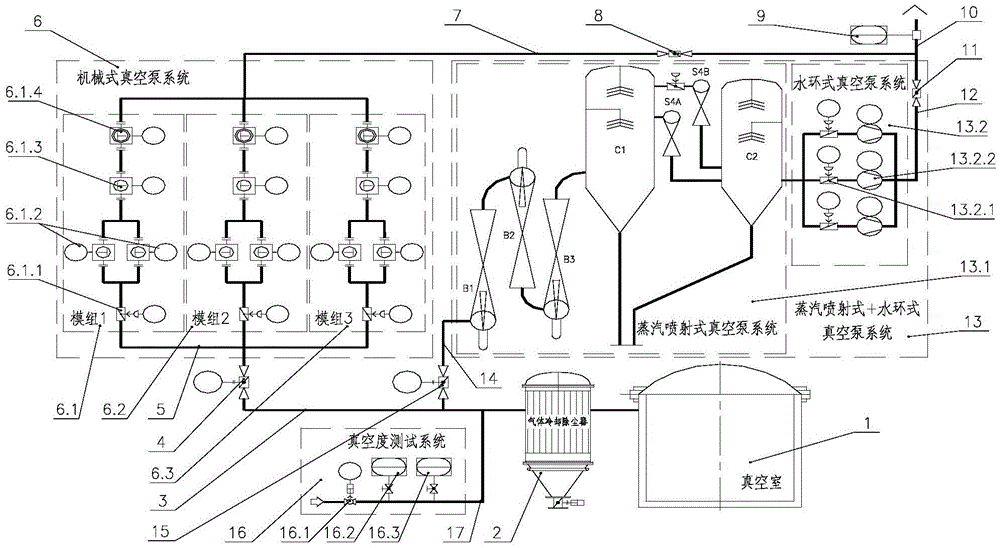

[0036] refer to image 3 , a hybrid vacuum pump system, including a vacuum chamber 1, the vacuum chamber 1 is connected to the inlet of a gas cooling dust collector 2 through a first suction pipe 3, and the outlet of the gas cooling dust collector 2 is divided into two branches: one branch passes through the third The air extraction pipeline 14 is communicated with the steam jet type (+water ring type) vacuum pump system 13, and a second vacuum shut-off valve 15 is installed on the branch; the other branch is communicated with the mechanical vacuum pump system 6 through the second air extraction pipeline 5, A first vacuum shut-off valve 4 is installed on the branch. According to the different volume of the vacuum chamber 1 and the tonnage of the molten steel contained in the vacuum chamber 1, the pumping capacity of the steam jet + water ring vacuum pump system 13 is required to be different. In this embodiment, it is assumed that the steam jet + water ring vacuum pump system ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com