A dyeing vat heat preservation device

A technology of a heat preservation device and a dyeing vat, which is applied in the field of dyeing vats, can solve the problems affecting the dyeing effect of dyeing machines, discomfort in the production environment of employees, and increase in workshop temperature, and achieve the effects of improving the working environment, reducing the heating time, and shortening the consumption time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

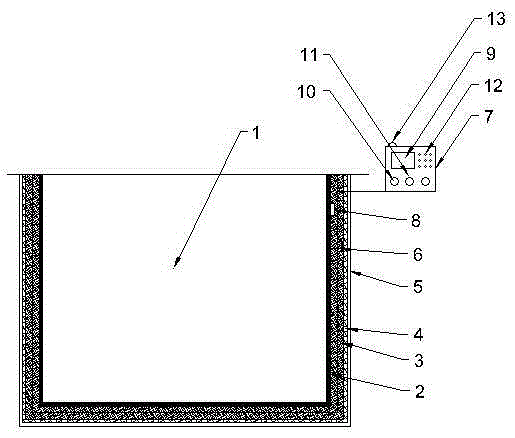

[0009] Below in conjunction with all accompanying drawings the present invention will be further described, and preferred embodiment of the present invention is: see appended figure 1 , the heat preservation device for the dyeing vat described in this embodiment includes a dyeing vat 1, an insulating coating 2, a ceramic fiber felt layer 3, a fireproof and high temperature resistant layer 4, and a stainless steel surface layer 5, wherein the outer surface of the dyeing vat 1 is coated with an insulating coating 2. The outer side of the thermal insulation coating 2 is covered with a ceramic fiber felt layer 3, and the ceramic fiber felt layer 3 is provided with an electric heating belt 6; Covered with an asbestos insulation layer, the outer surface of the asbestos insulation layer is coated with a heat insulation coating; the outside of the heat insulation coating is provided with a stainless steel surface layer 5; the electric heating belt 6 is distributed in the ceramic fiber ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap