The construction method of manual excavation pile

A technology of artificial digging piles and construction methods, which is applied to sheet pile walls, foundation structure engineering, construction, etc., can solve the problems of small resistance, large bending moment, interference, etc., to increase passive earth pressure, expand contact area, reduce Effect of diameter and burial depth

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] The present invention will be described in further detail below through specific implementation examples and in conjunction with the accompanying drawings.

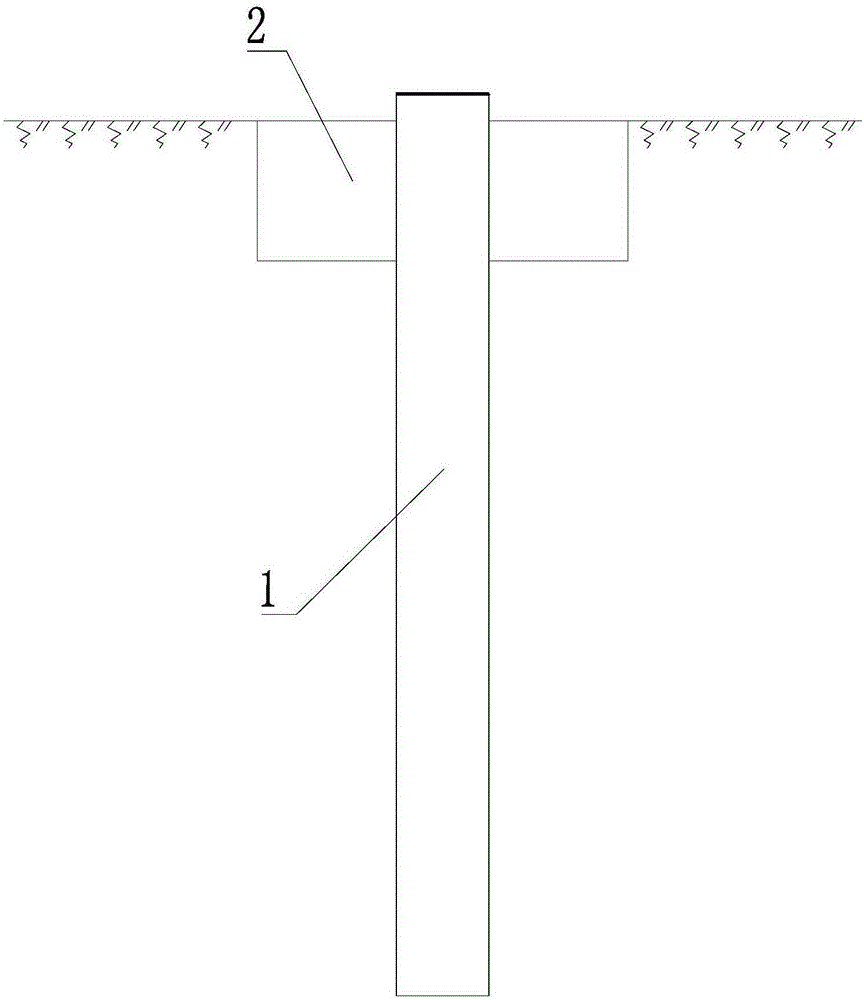

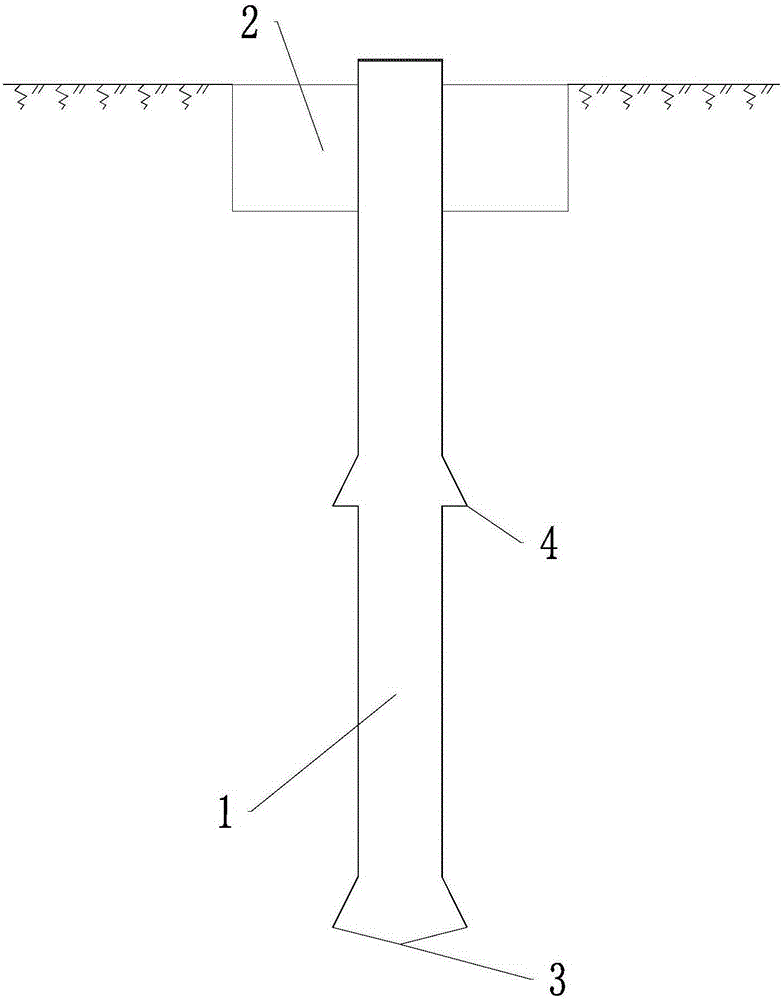

[0040] figure 1 It is the manual hole-digging pile provided by the first embodiment of the present invention, such as figure 1 As shown, the artificial hole-digging pile provided by the first embodiment of the present invention includes a main body 1 and a wing plate 2, the main body 1 is a cylinder including two ends and a side wall, and one end of the main body 1 is provided with two identical rectangular wings Plate 2, the rectangular wing plate 2 is arranged on the side wall of the main body 1, the top surface of the wing plate 2 is flush with the end surface of the main body 1, and the wing plate 2 extends along the axis direction of the main body 1.

[0041] The wing plate 2 is arranged at one end of the main body 1, and two identical wing plates 2 are arranged at one end of the main body 1. The top surface ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com