Locking mechanism for preventing interlink impact inertia accidental vehicle door opening

An inertial, door technology, applied in the direction of locks, building locks, handle connections, etc. in the event of an accident, which can solve problems such as accidental opening of the door, inability to ensure that the handle fits the door, causing accidents, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

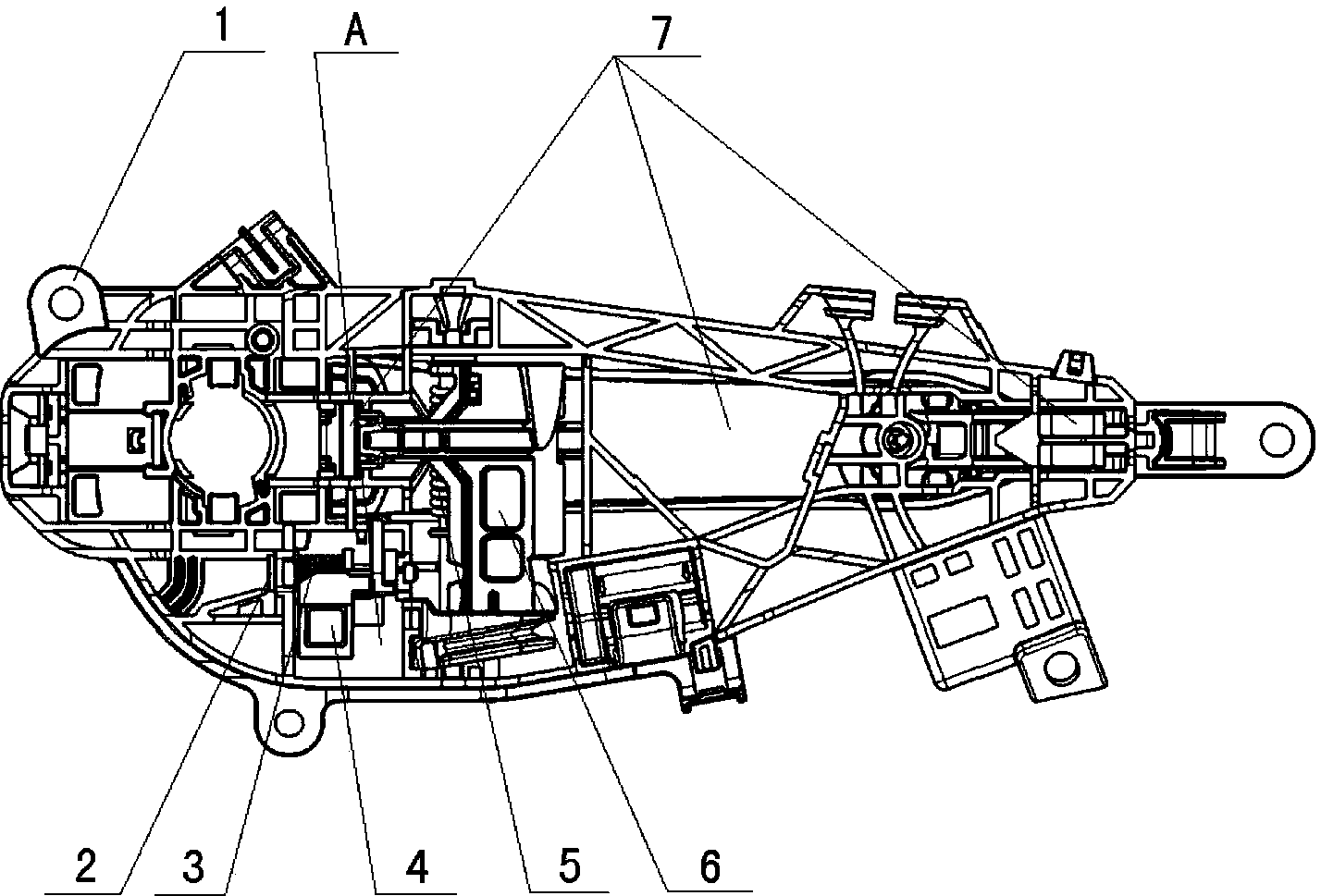

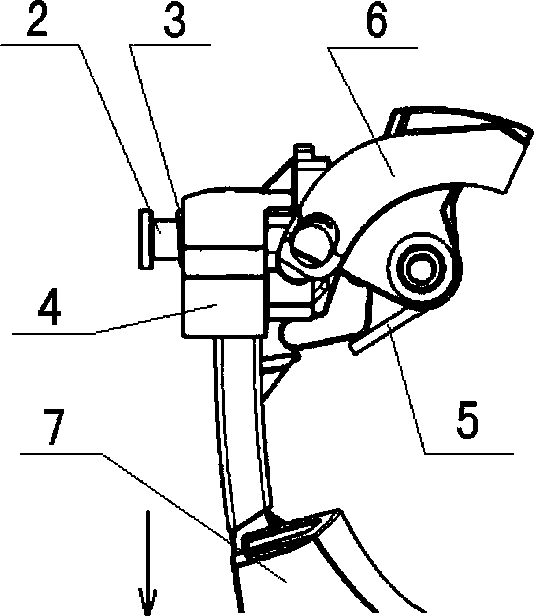

[0024] A locking mechanism for preventing serial impact and inertial accidental door opening, comprising a base 1, a rotating shaft 2, a locking return torsion spring 3, an inertia locking block 4, a balance return torsion spring 5, a balance weight 6 and a handle body 7 ,Such as figure 1 As shown, the specific structure is:

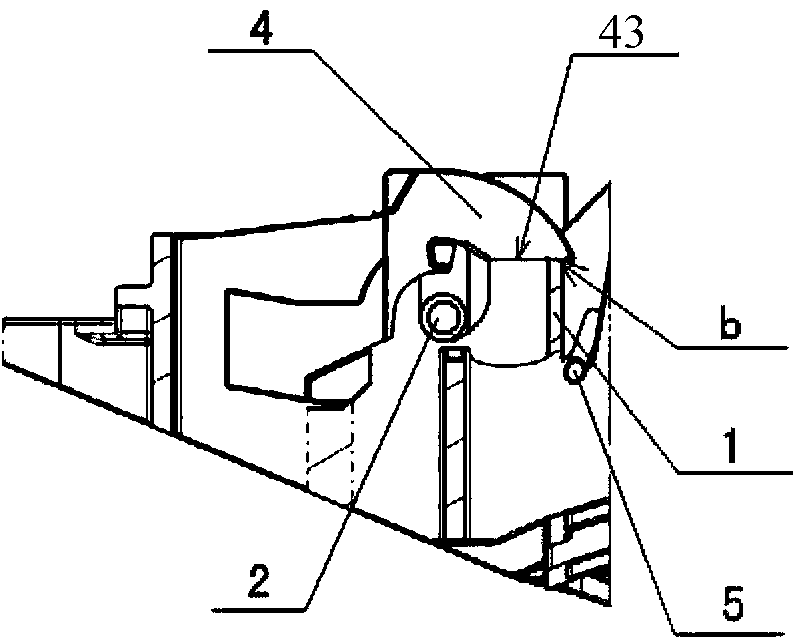

[0025] There is a locking block groove on the base 1, and the locking block groove is as figure 1 As shown in middle A, the rotating shaft 2 is covered with a locking return torsion spring 3, and the two ends of the rotating shaft 2 pass through the two ends of the inertia locking block 4 respectively, and then are respectively embedded on the inner walls of the locking block groove on both sides. The two ends of the non-return torsion spring 3 are against the locking block groove and the inertia locking block 4 respectively;

[0026] Inertia lock block 4 as Figure 6 As shown, it is composed of a lock block 41, a lock wheel 42 and a lock claw 43, the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com