Stage pressurization air supply system

A technology of air supply system and pressurization system, which is applied to liquid variable volume machinery, pump devices, machines/engines, etc., can solve problems such as energy waste, and achieve the effect of improving energy utilization efficiency and high energy utilization efficiency.

Inactive Publication Date: 2014-10-29

WUXI GL TUBRO COMPRESSOR

View PDF5 Cites 12 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

However, this way of stepping down the

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Login to View More

Login to View More PUM

Login to View More

Login to View More Abstract

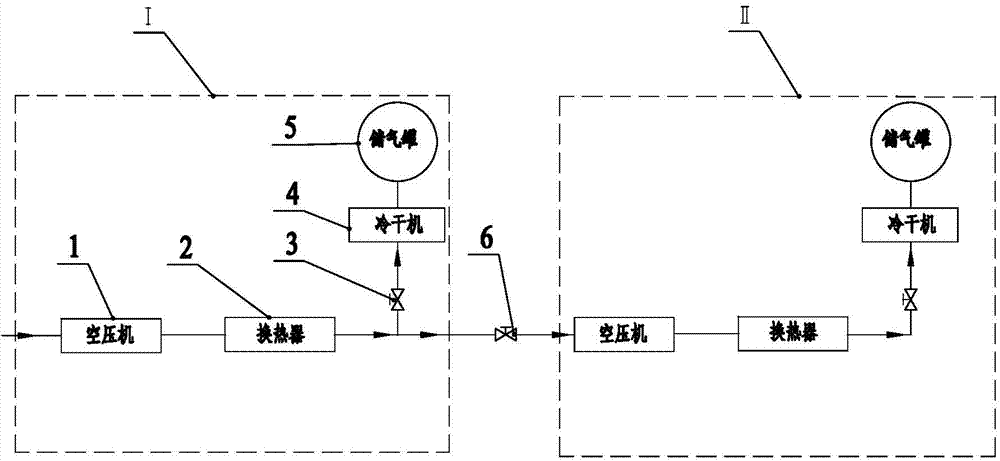

The invention relates to a stage pressurization air supply system. The stage pressurization air supply system is characterized by comprising pressurization subsystems of two or more stages. Each pressurization subsystem comprises an air compressor, a heat exchanger, a dryer, a gate valve and an air storage tank. Air is sucked through the inlets of the air compressors, the outlets of the air compressors are connected with the inlets of the heat exchangers through pipelines, the outlets of the heat exchangers are connected with the inlets of the dryers through pipelines and the gate valves, and the outlets of the dryers are connected with the air storage tanks through pipelines. The inlet of the air compressor of the pressurization subsystem of the first stage is connected with the air and used for sucking into natural air. The inlets of the pressurization subsystems of the second stage and the subsequent stages are respectively connected to a pipeline behind the corresponding gate valve of the pressurization subsystem of the corresponding former stage through pipelines and the series-connected gate valves. The stage pressurization air supply system is high in utilization efficiency of the energy resources. Pressurization is carried out stage by stage through the pressurization subsystems of two or more stages, and therefore different pressure requirements can be met. Unnecessary energy source waste in the air supply process is avoided. Compared with a traditional pressure reduction scheme, the utilization efficiency of the energy resources is greatly improved.

Description

technical field [0001] The invention relates to an air supply system, in particular to a novel staged pressurized air supply system, which belongs to the field of energy utilization. Background technique [0002] Air compressor stations are widely used in industrial production. It is responsible for providing air source for all pneumatic components (including various pneumatic valves). Therefore, the operation of the air compressor station directly affects the production process. In use, the needs of each link are different, and the gas consumption and gas pressure are very different. [0003] In the prior art, according to different pressure requirements, the air supply of general air compressor stations directly outputs the highest pressure, and then reduces the pressure through the pressure reducing valve to reduce the pressure to the pressure required by various pneumatic components. However, this way of depressurizing gas supply means huge waste of energy. Contents...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): F04B41/02F04B41/06

Inventor 龚一方冯晨远王青

Owner WUXI GL TUBRO COMPRESSOR

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Patsnap Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com