A Calculation Method of Homography Matrix h for Single Line Array Camera

A technology of homography matrix and calculation method, applied in calculation, image data processing, instrument, etc., can solve the problems of increased system complexity, difficult speed setting, deformation, etc., to achieve the effect of simple system and less restrictive conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] In order to better understand the technical solutions of the present invention, the implementation manners of the present invention will be described in detail below in conjunction with the accompanying drawings.

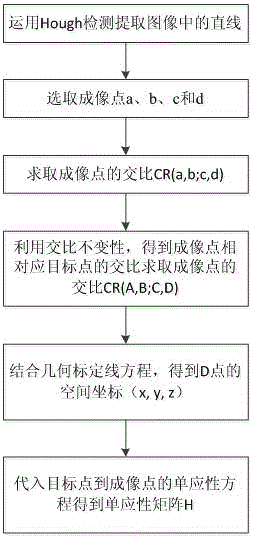

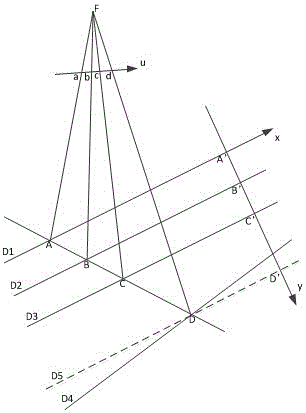

[0035] Such as figure 1 As shown, the present invention first performs Hough operation on the obtained image to obtain the straight line in the image, and selects the target point to calculate the cross ratio. According to the characteristics of the single line array camera imaging system, the cross-ratio of the target point is obtained by combining the invariance of the cross-ratio. Use the equation of the calibration line in the calibration plate to obtain the coordinates of point D.

[0036] The concrete implementation of the present invention is as follows:

[0037] 1. Use the Hough algorithm to extract the lines in the image captured by the single-line array camera, take a line in the image plane, and intersect this line with the captured 4-line calibr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com