Control method for light field in holographic printing technology and its system

A printing technology and a control method technology, which are applied in the field of spatial periodic lattice position control method and system thereof, can solve the problems of unstable light field phase exposure effect, inability to form periodic pattern exposure map, increase in feature size, etc., and achieve high stability flexibility and controllability, reducing system complexity, reducing the effect of width

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The present invention will be further described below in conjunction with the accompanying drawings.

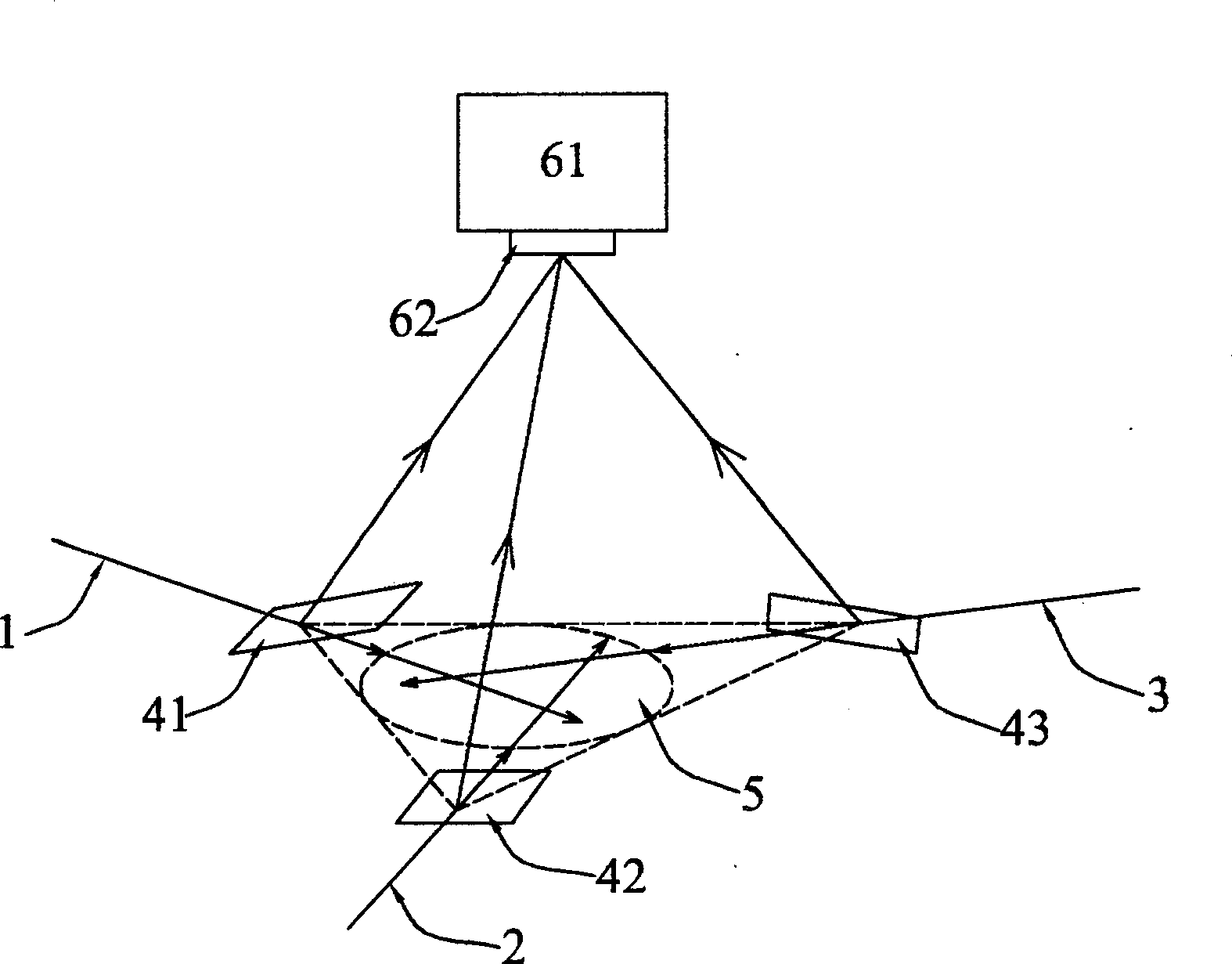

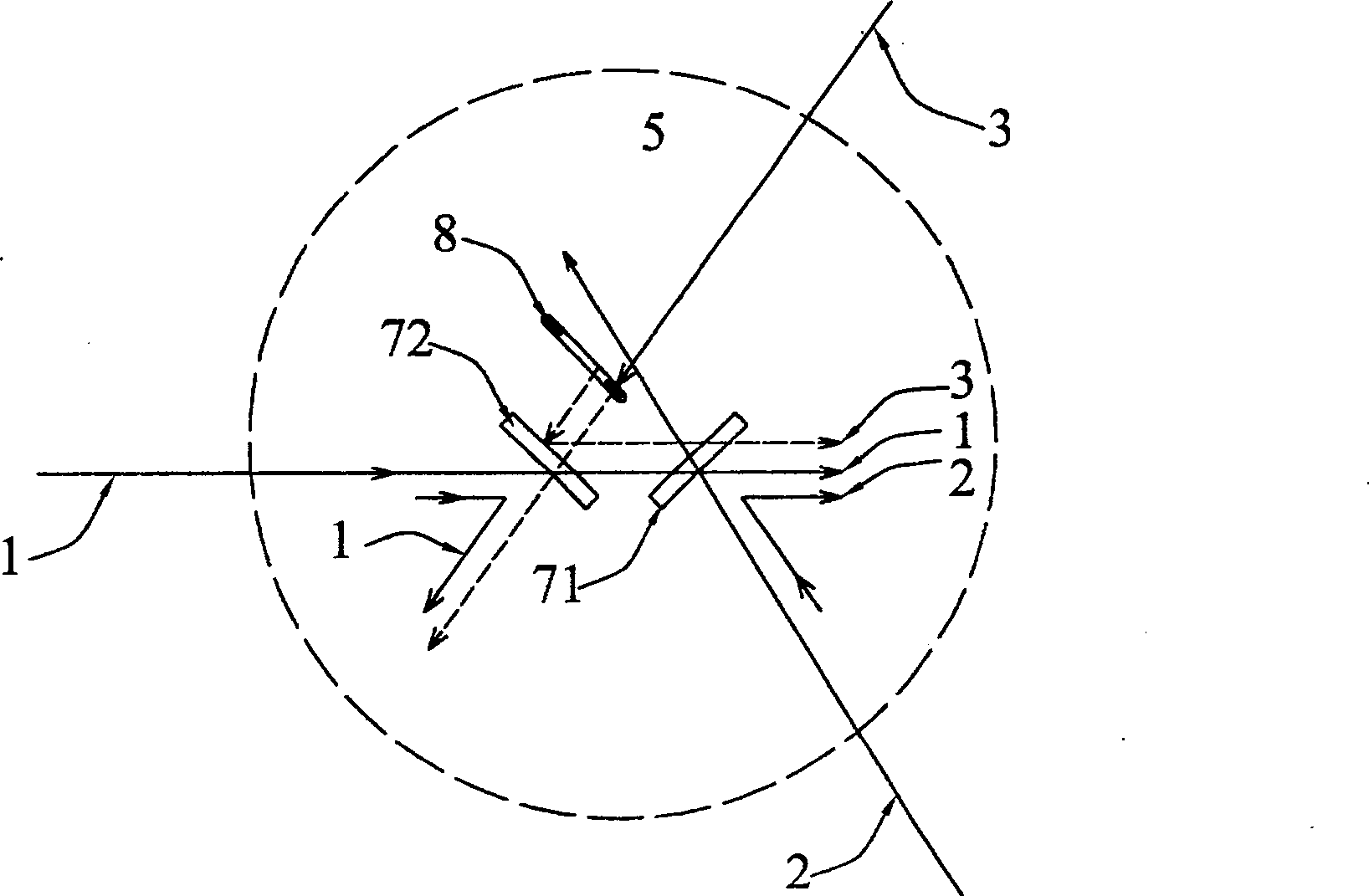

[0039] Take the holographic printing light field formed by three beams of light as an example to illustrate the present invention, the light path diagram of the light field is as follows figure 1 As shown, the three incident He-Ne lasers 1, 2 and 3 are reflected to the CCD61 by three half-mirrors 41, 42 and 43, and the three beams are not collinearly intersected, forming spatial interference at the intersection point The grid can be observed by CCD61. The present invention adopts the method of adding ccd61 to microscope 62 to recombine and amplify the light in microscope 62 and observe with ccd61, so that the effect of control can be observed conveniently and directly in real time. The three beams of light 1, 2 and 3 passing through the half-mirrors 41, 42 and 43 intersect on a plane, such as area 5 in the figure, and area 5 is the plane for realizing system control. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com