E1 vertical roll of plate strip rolling mill

A technology of vertical rolls and rolling mills, which is applied in the direction of rolls, metal rolling, metal rolling, etc., and can solve problems such as ineffective effects and increasing the quality of strips

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

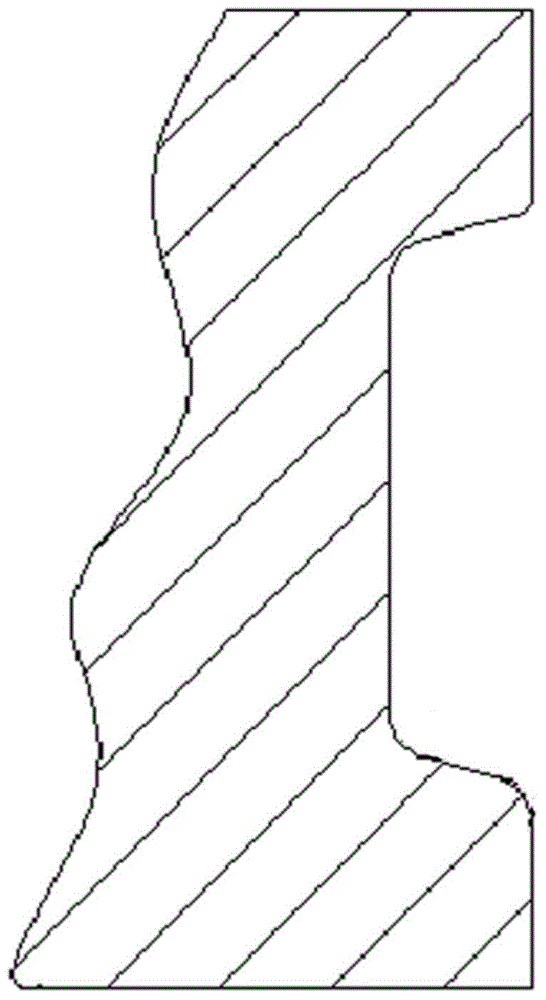

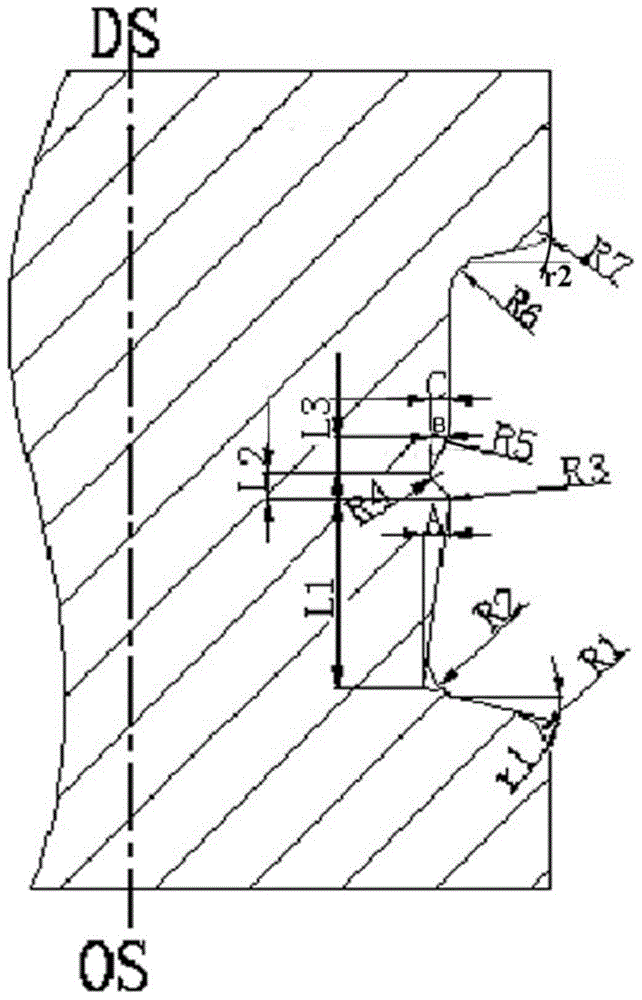

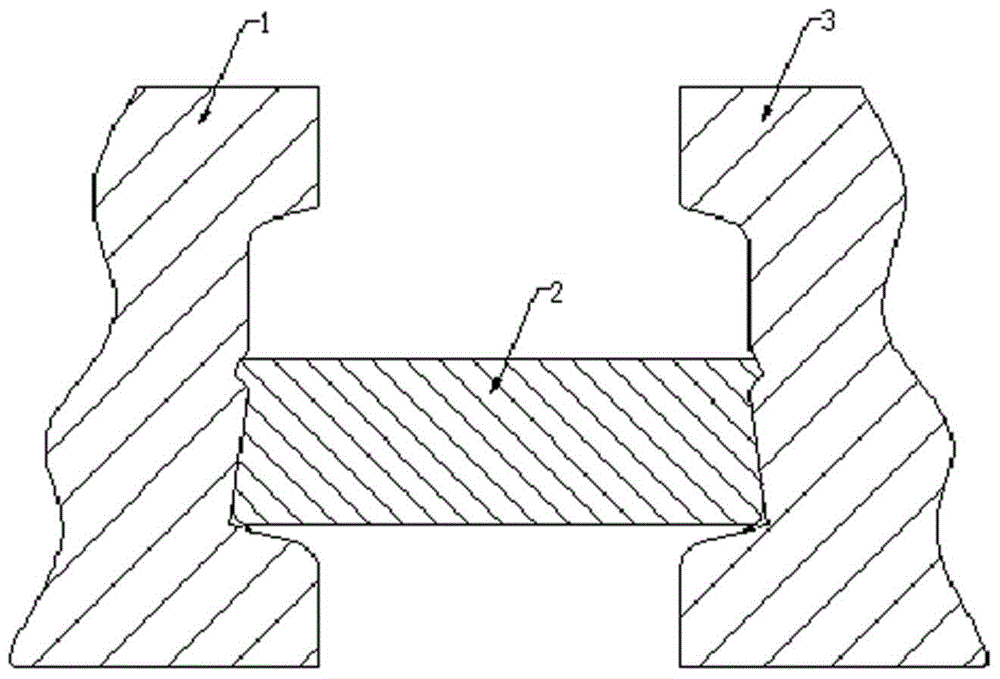

[0028] see figure 2 , a kind of plate and strip rolling mill E1 vertical roll provided by the embodiment of the present invention, the groove bottom of the vertical roll groove hole includes a groove and an inclined surface, the groove includes the upper slope of the groove and the lower slope of the groove, the upper slope of the groove and the lower slope of the groove There is a smooth transition between the lower inclined surfaces of the grooves, and a smooth transition between the inclined surfaces and the lower inclined surfaces of the grooves. The length of the central axis DS-OS of the vertical roller corresponding to the inclined surfaces is L1, and the length of L1 is greater than h. The thickness of a rough rolling flat roll stand in the second pass, L1+L2H.

[0029] The taper between the lower inclined surface of the groove and the central axis DS-OS of the vertical roller is B / L2, and the length of the central axis DS-OS of the vertical roller corresponding to th...

Embodiment 2

[0035] An E1 vertical roll of a strip mill provided by an embodiment of the present invention, the groove bottom of the vertical roll hole includes a groove and an inclined surface, the groove includes an upper slope and a lower slope, and the upper slope and the groove There is a smooth transition between the inclined surfaces of the grooves, and a smooth transition between the inclined surfaces and the lower inclined surfaces of the grooves. The length of the DS-OS part of the central axis of the vertical roller corresponding to the inclined surfaces is L1, and the length of L1 is greater than h. The thickness of a rough rolling flat roll stand in the second pass, L1+L2H.

[0036] The taper between the lower inclined surface of the groove and the central axis DS-OS of the vertical roller is B / L2, and the length of the central axis of the vertical roller corresponding to the lower inclined surface of the groove is L2; the upper inclined surface of the groove and the central ...

Embodiment 3

[0042] An E1 vertical roll of a strip mill provided by an embodiment of the present invention, the groove bottom of the vertical roll hole includes a groove and an inclined surface, the groove includes an upper slope and a lower slope, and the upper slope and the groove There is a smooth transition between the inclined surfaces of the grooves, and a smooth transition between the inclined surfaces and the lower inclined surfaces of the grooves. The length of the DS-OS part of the central axis of the vertical roller corresponding to the inclined surfaces is L1, and the length of L1 is greater than h. The thickness of a rough rolling flat roll stand in the second pass, L1+L2H.

[0043] The taper between the lower inclined surface of the groove and the central axis DS-OS of the vertical roller is B / L2, and the length of the central axis DS-OS of the vertical roller corresponding to the lower inclined surface of the groove is L2; the upper inclined surface of the groove and the ce...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com