Workpiece straightening machine and its straightening method

A technology for straightening machines and workpieces, which is applied in shaft and workpiece straightening machines and the field of straightening, which can solve problems such as over-bending, insufficient bending of workpieces, unsatisfactory control of bending amount and pressure head stroke, etc., so as to avoid insufficient bending , Reduce precision control requirements, improve the effect of production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

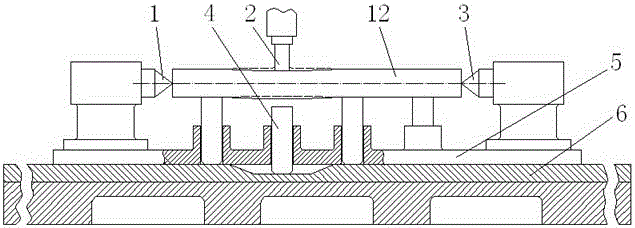

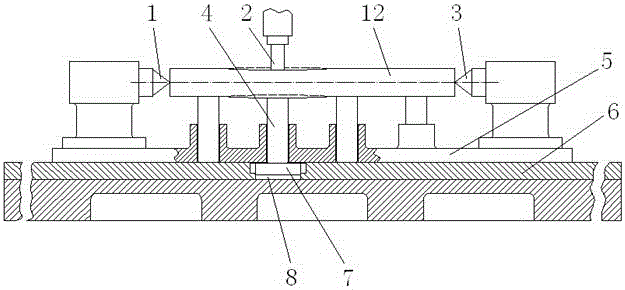

[0021] Such as figure 2 As shown, the workpiece straightening machine includes a follower thimble 1, a pressure head 2, a driving thimble 3, a pressure supporting pillar 4, a working slide 5, a pressure bearing plate 6, a pressure measuring component and a bending amount control device. The follow-up thimble 1, the pressure supporting pillar 4 and the driving thimble 3 are set on the working slide 5 and can move together with the working slide 5 (that is, they can move left and right), while the pressure head 2 and the pressure bearing plate 6 are opposite to the working slide 5 still. The working slide table 5 is arranged on the pressure bearing plate 6 and is slidably engaged with the pressure bearing plate 6 .

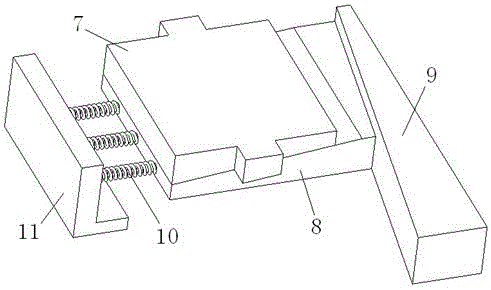

[0022] The structure of the bending amount control device is as follows: image 3 As shown, the bending amount contro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com