Novel electric stapler

A stapler and electric technology, applied in the direction of nail staple tools, manufacturing tools, etc., can solve the problems of reducing work efficiency, time-consuming and labor-intensive, and the use of power plugs is not very convenient, so as to improve work efficiency, avoid calculation, structure, etc. simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

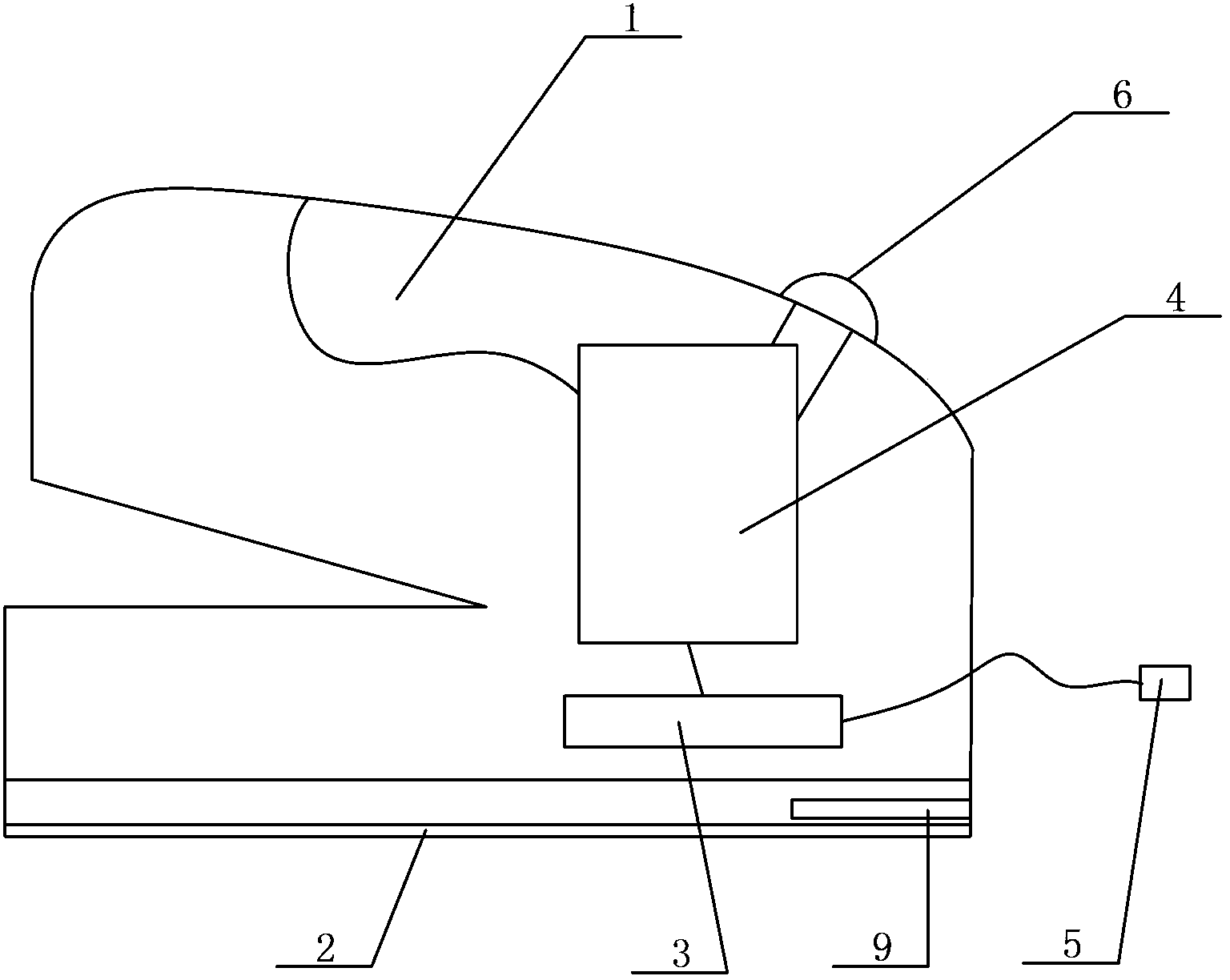

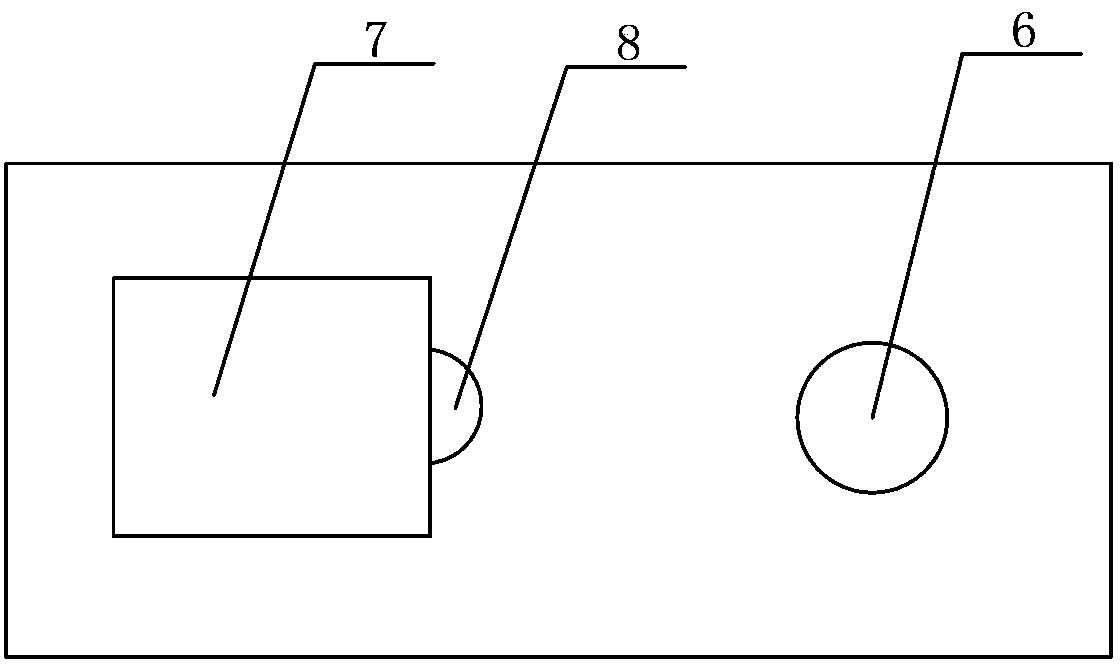

[0011] Reference figure 1 with figure 2 , This specific implementation adopts the following technical solutions: it includes stapler body 1, anti-skid layer 2, battery 3, drive mechanism 4, USB interface 5, switch 6, display screen 7, reset button 8; stapler body 1 There is a non-slip layer 2 on the bottom of the stapler body 1, a battery 3 and a driving mechanism 4 are provided in the stapler body 1, the driving mechanism 4 is connected to the battery 3, the battery 3 is connected to the USB interface 5, and the driving mechanism 4 is connected to the upper part of the stapler body 1. The switch 6 is connected, and the stapler body 1 is provided with a display screen 7 and a reset button 8. The reset button 8 is connected with the display screen 7, and the display screen 7 is connected with the driving mechanism 4.

[0012] The bottom of the stapler body 1 is provided with a pull-out nail removing device 9.

[0013] During the operation of this embodiment, the battery 3 is charg...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com