Discharging machine

A cutting machine and unloading technology, applied in the direction of conveyor objects, transportation and packaging, can solve the problems of low efficiency, complex structure, waste of manpower and material resources, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

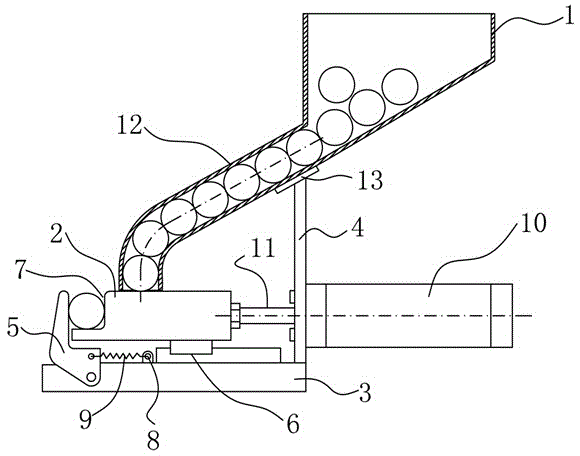

[0014] like figure 1 As shown, a blanking machine described in the embodiment of the present invention is mainly used in the blanking work in the steel ball production line, and mainly includes a main body, a material bin 1 for holding steel balls, a blanking mechanism 2 and a clamping The claw 5, the main body includes a mounting plate 3 and a support plate 4 perpendicular to the mounting plate 3, the unloading mechanism 2 is located on the mounting plate 3 and is connected with the mounting plate 3 through a linear guide rail 6, and one side of the unloading mechanism 2 is provided with The gap 7, the clamping claw 5 is hinged with the mounting plate 3 and forms an accommodation space with the gap 7 of the blanking mechanism 2, and a connecting ear seat 8 is arranged between the clamping claw 5 and the linear guide rail 6, and the clamping claw 5 is connected to the Springs are connected between the lugs 8, and the other side of the blanking mechanism 2 is connected with the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com