Cutter head structure of ultrathin glass transverse-cutting machine

An ultra-thin glass, cross-cutting machine technology, applied in glass cutting devices, glass production, glass manufacturing equipment, etc., to achieve the effect of reducing broken boards, high pressure regulation accuracy, and increasing knife drop buffer

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

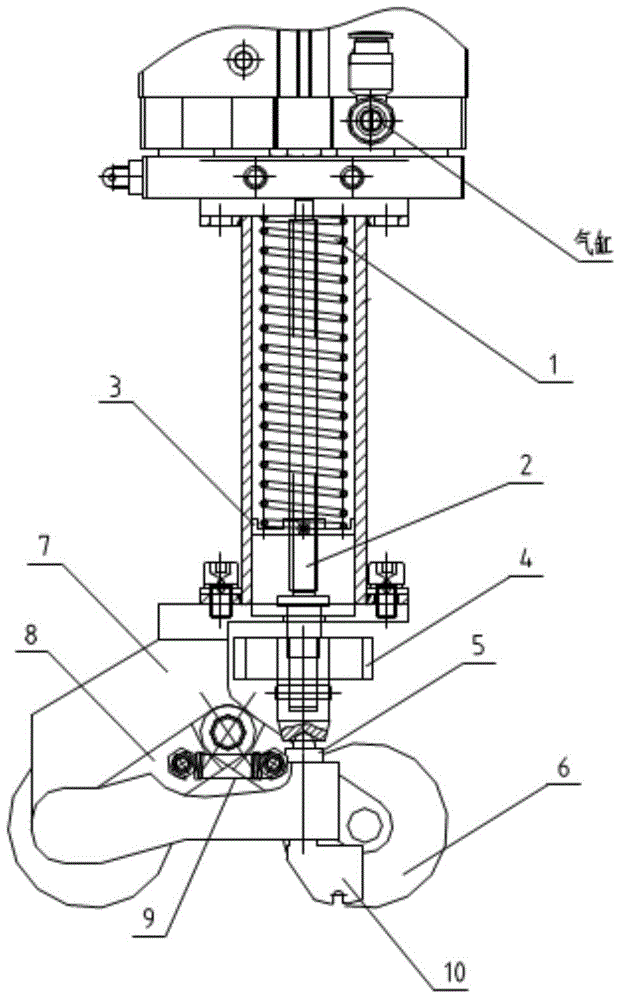

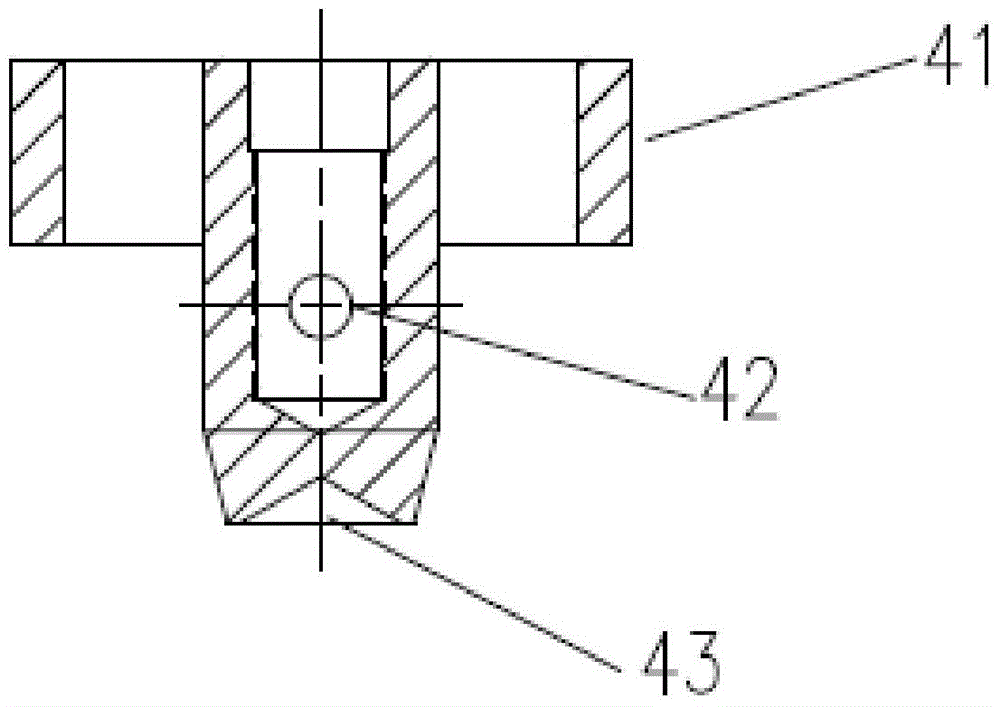

[0016] Such as figure 1 as shown, one A cutting head structure for an ultra-thin glass cross-cutting machine, including a knife box and a knife head assembly installed at the end of the knife box, the knife box includes a knife box, the top of the knife box is sealed, the bottom is open, and a guide rod is built in 2 and the nut disc 3, the top of the guide rod 2 is located inside the top of the knife box, the bottom end stretches out of the knife box and is fixedly connected to the tappet 4 by the positioning pin 42, and the lower part of the middle is threadedly assembled with the nut disc 3; The nut disc 3 is also connected with a cylindrical helical spring 1 around the guide rod 2, the other end of the cylindrical helical spring 1 is located at the top of the knife box; the bottom end of the tappet 4 is connected with a protruding rod 5, and the protruding rod 5 is connected The bottom end of the rod is threadedly connected to the rotating member, and the cutter head cla...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com