Vertical-axis wind driven generator

A technology of wind power generators and vertical axes, applied in the direction of wind power generators, wind power motor combinations, wind power generators at right angles to the wind direction, etc., which can solve problems such as unstable cost, complex structure of speed limiting device, and difficulty in starting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

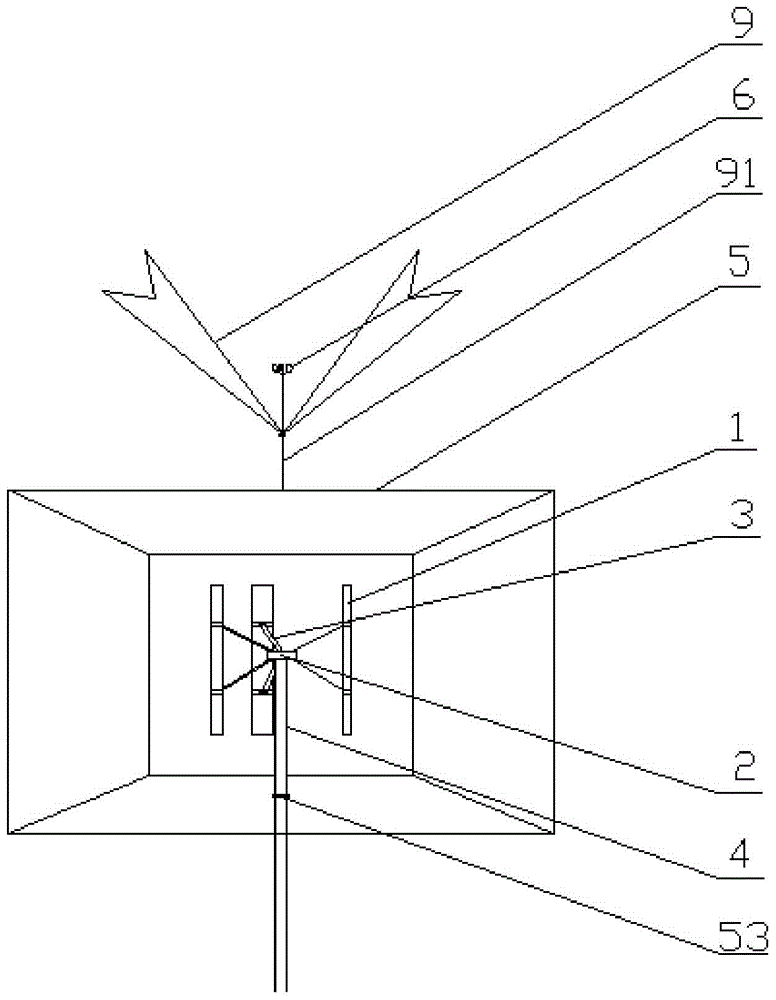

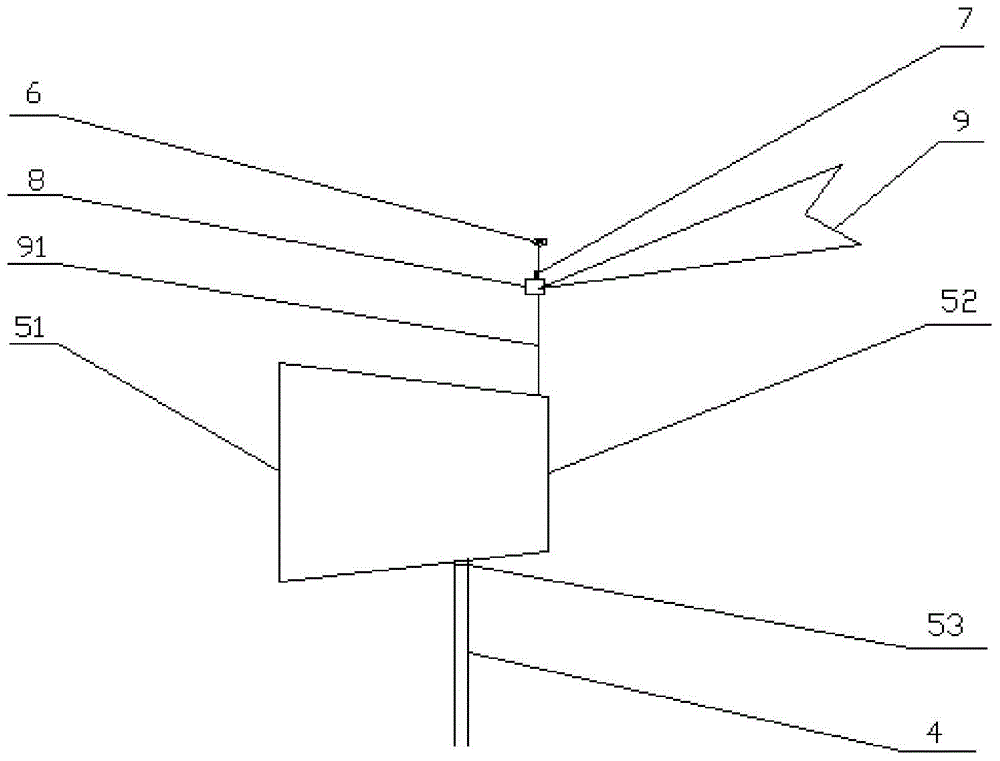

[0018] Embodiment 1: A vertical axis wind power generator, including a blade 1, a disc motor 2, a blade support 3, and a column 4. The vertical axis wind power generator also includes a wind shield 5, a wind speed sensor 6, Controller 7, angle adjustment device 8, and tail 9; wind speed sensor 6 is used to sense wind speed, and transmit the wind speed signal to controller 7, controller 7 analyzes the wind speed signal, when the wind speed is greater than the rated wind speed of the wind turbine, the controller 7 controls The angle adjustment device 8 changes the angle of the tail fin 9 to block the wind baffle 5, thereby limiting the rotation speed of the blade 1. When the wind speed is less than the rated wind speed of the wind turbine, the controller 7 controls the angle adjustment device 8 to change the angle of the tail 9 The wind baffle 5 collects wind, so as to collect wind energy to increase the speed of the blade 1. This design can also separate the speed limiting device...

Embodiment 2

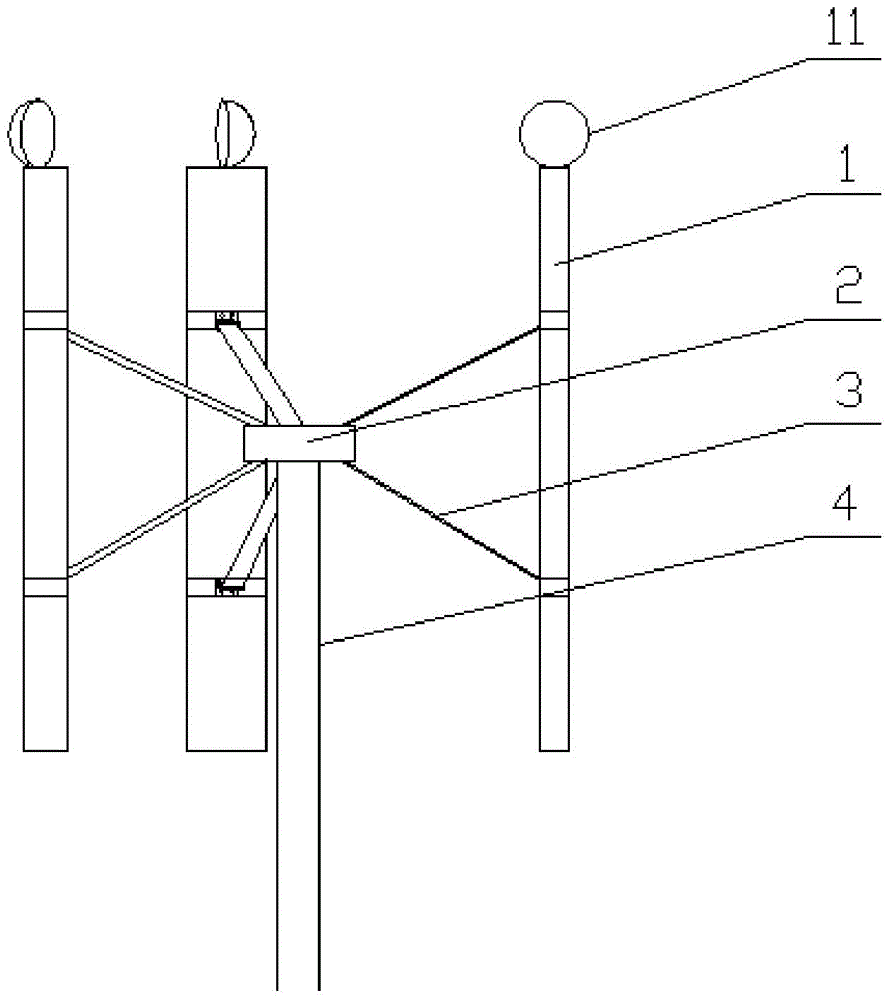

[0023] Embodiment 2: On the basis of embodiment 1, the wind blade 1 is also provided with a start wind cup 11, because the rotation of the wind blade 1 requires a relatively large force to start, so when the wind speed is small, the wind cup can be rotated The rotation force is provided to drive the rotation of the blades, which can avoid using a starter motor to drive the blades to rotate.

Embodiment 3

[0024] Embodiment 3: On the basis of embodiment 1, the disc motor 2 is also provided with an irreversible disc 21, and the irreversible disc 21 is provided with a starting wind cup 22, which is designed to be rotated when starting The wind cup 22 drives the wind blade 1 to reduce the starting wind speed. When the wind speed increases, the resistance of the starting wind cup 22 increases faster, and the rotation speed of the wind blade 1 is greater and will not be affected by the wind cup.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com