An aerosol generating device and system with improved airflow

An aerosol generation and aerosol technology, applied in the direction of electric heating devices, electrical components, inhalers, etc., can solve the problems of discomfort, device heat, etc., and achieve the effect of low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

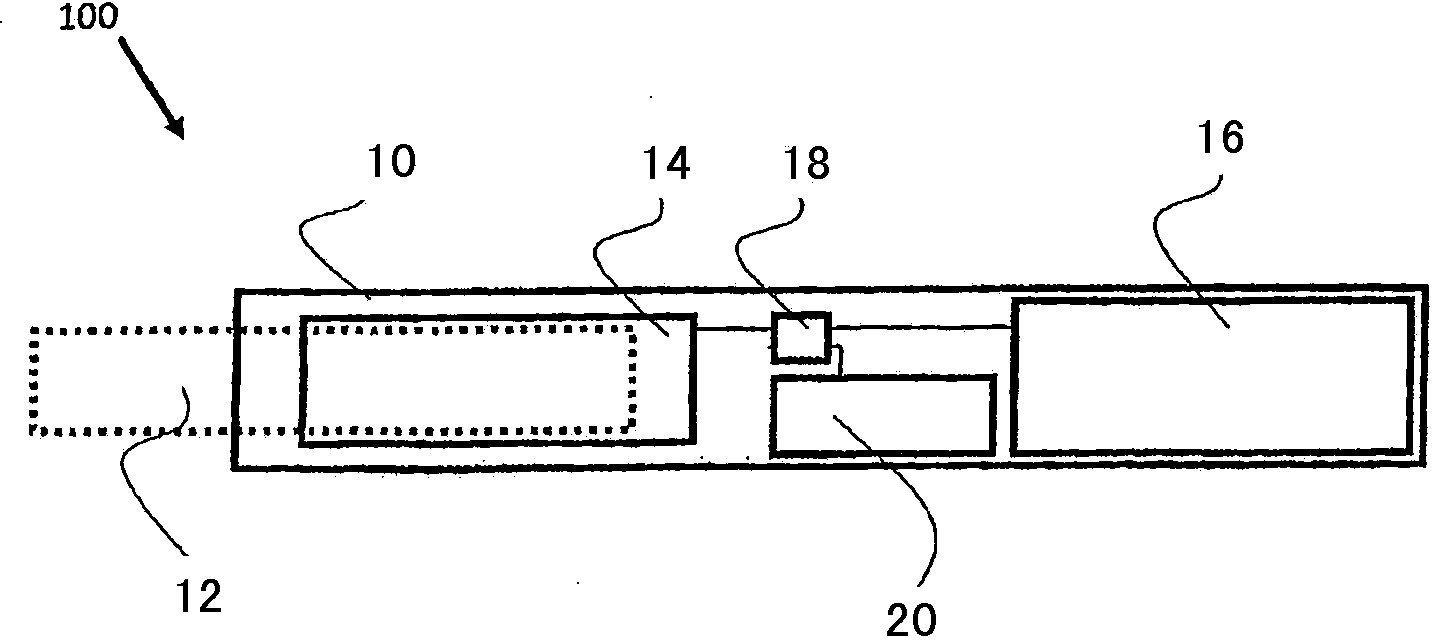

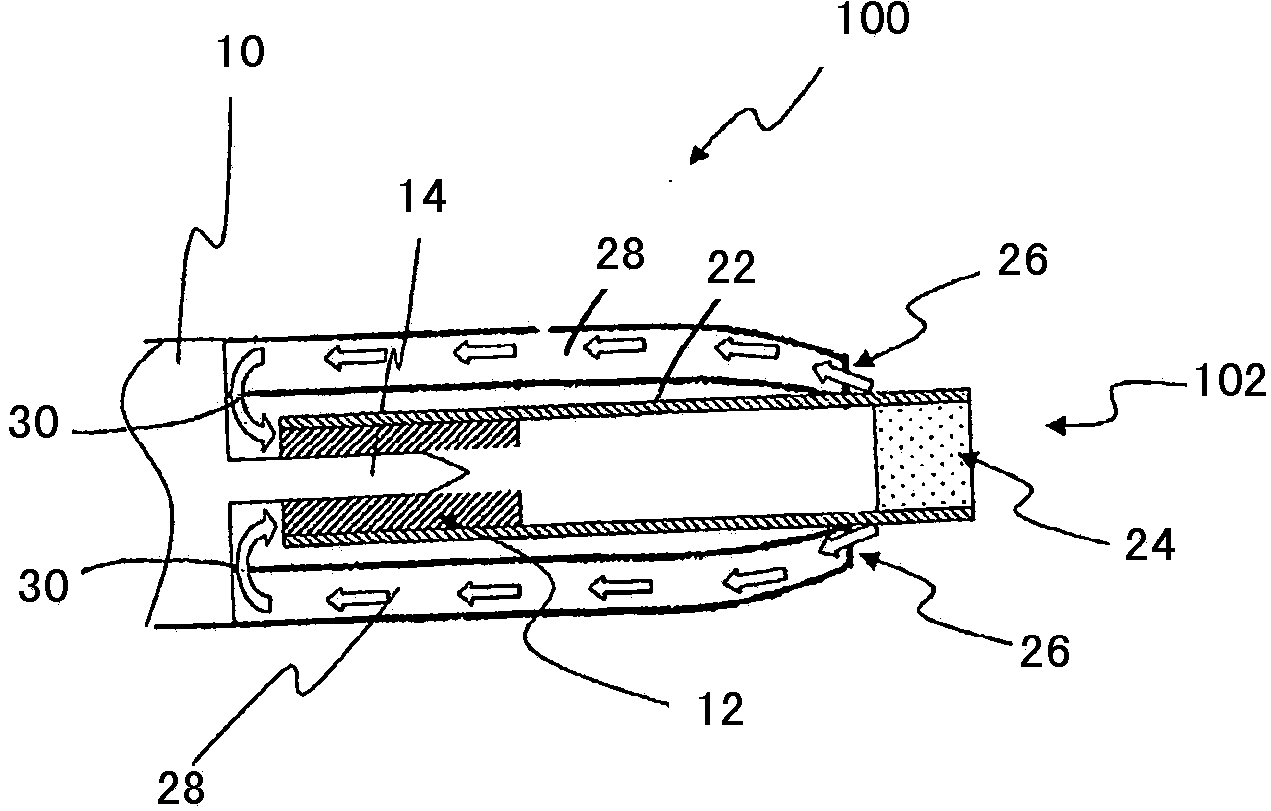

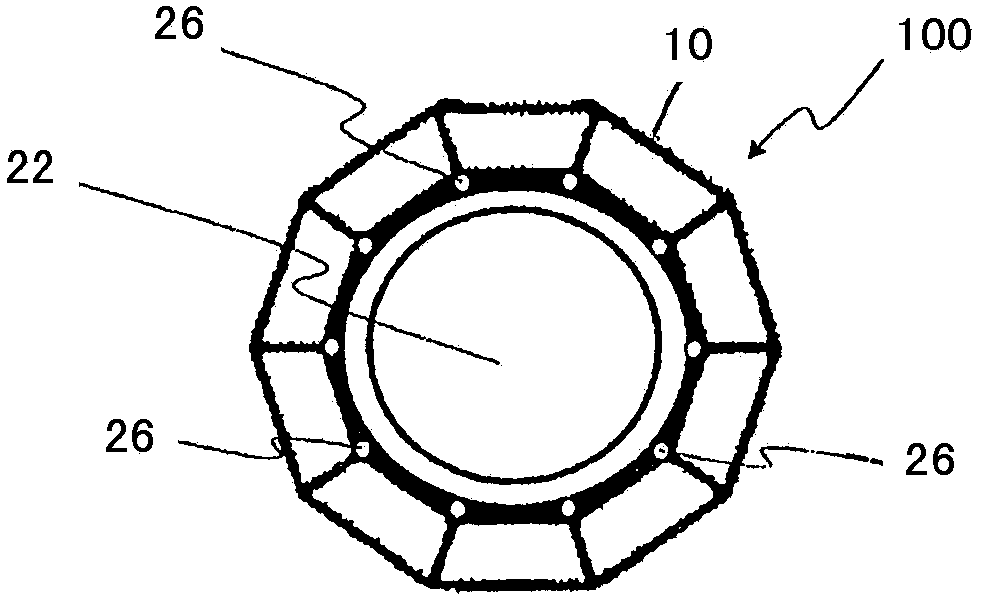

[0062] exist figure 1 In, the components of one embodiment of an electrically heated aerosol generating system 100 are shown in a simplified manner. In particular, in figure 1 The components of the electrically heated aerosol generating system 100 are not drawn to scale. Elements not relevant to the understanding of this embodiment have been omitted to simplify figure 1 .

[0063] The electrically heated aerosol-generating system 100 includes a housing 10 and an aerosol-forming substrate 12, such as a cigarette. The aerosol-forming substrate 12 is pushed into the interior of the housing 10 into thermal proximity with the heater 14 . The aerosol-forming substrate 12 will release a range of volatile compounds at different temperatures. The release or formation of certain volatile compounds can be avoided by controlling the maximum operating temperature of the electrically heated aerosol generating system 100 to be below the release temperature of some volatile compounds.

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com