Self-cleaning vibration drum screen with adjustable inclination angle

A trommel screen and self-cleaning technology, which is applied in the direction of filter screen, solid separation, grille, etc., can solve the problems of low screening rate, easy blockage of screen holes, small screening capacity, etc., so as to improve screening efficiency and expand the scope of use , the effect of preventing sieve clogging

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

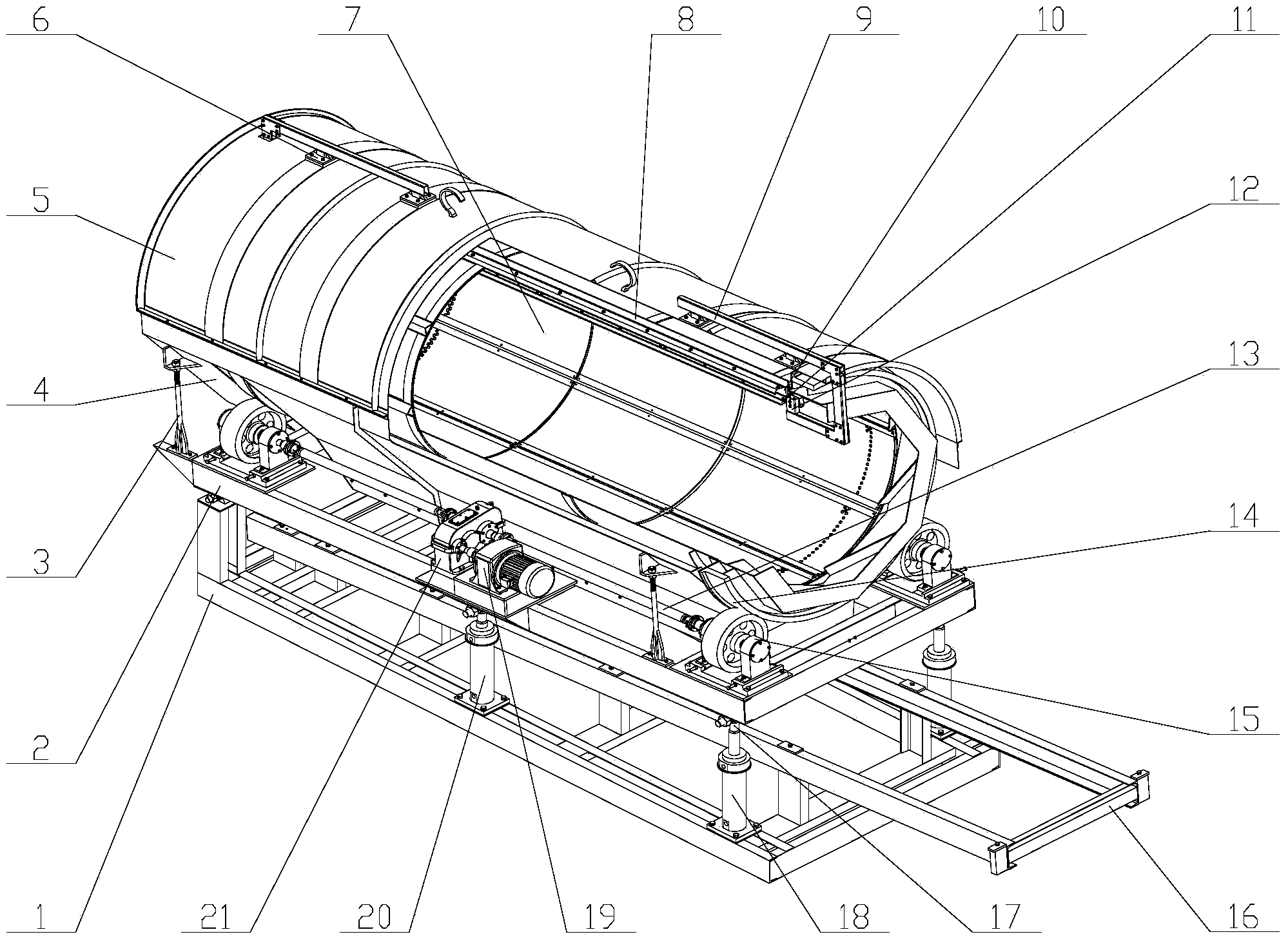

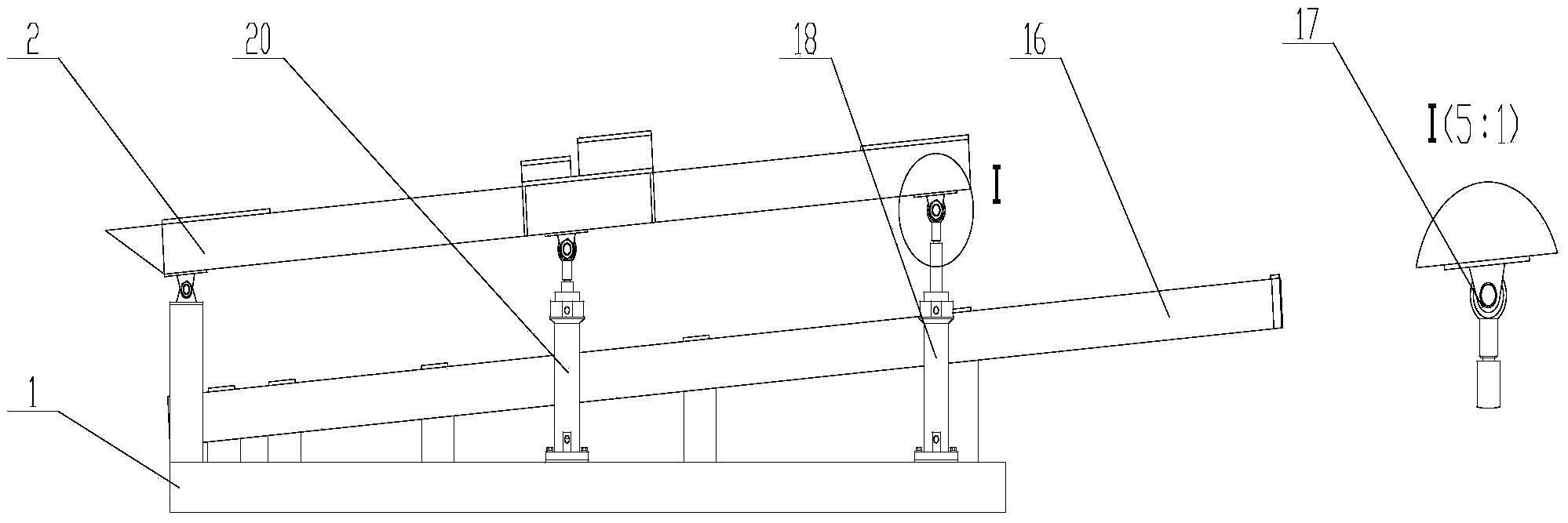

[0016] The specific implementation, structure, features and effects of the self-cleaning vibrating drum screen with adjustable inclination angle proposed by the present invention will be described in detail below in conjunction with the accompanying drawings.

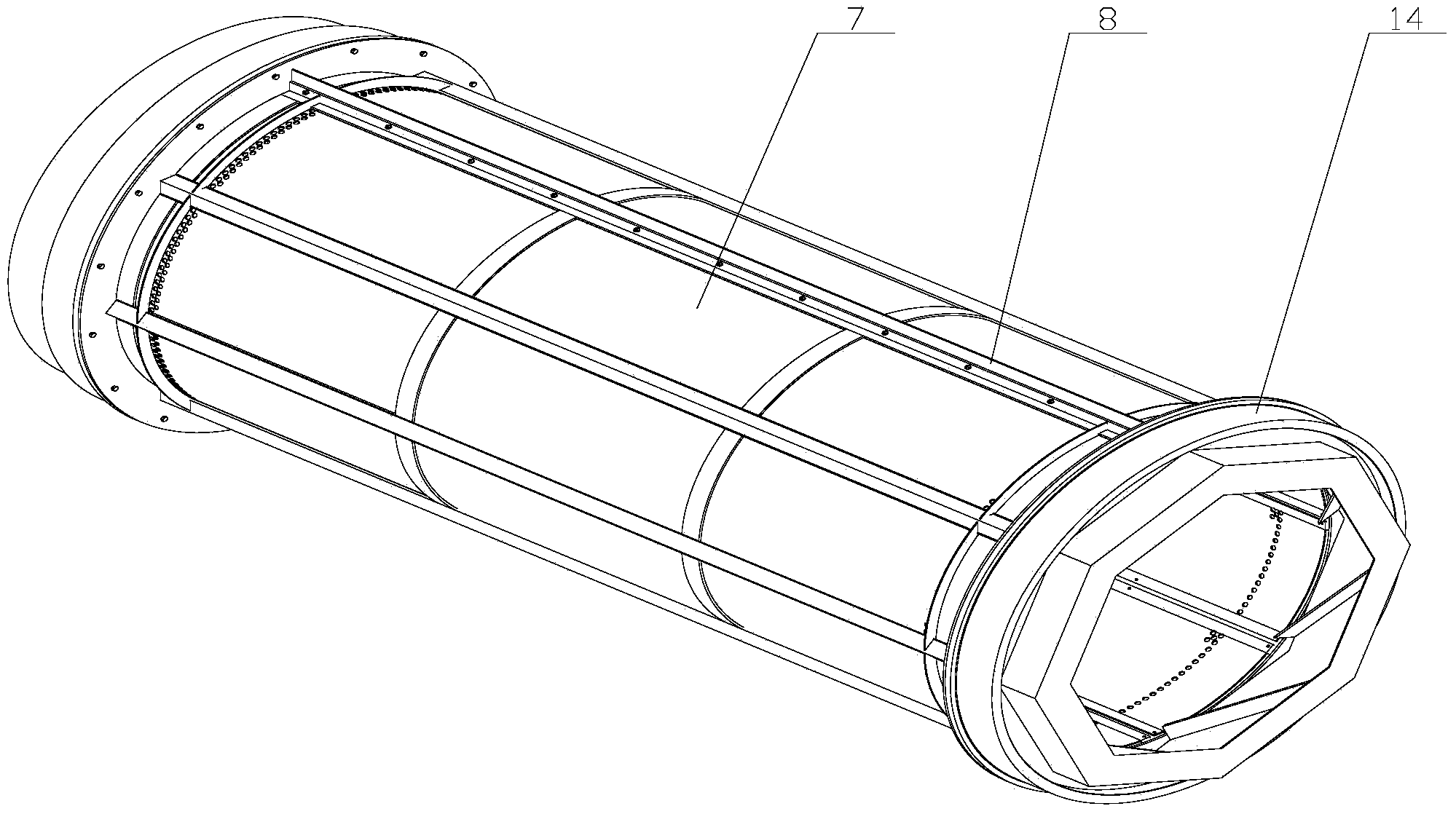

[0017] exist figure 1 In the three-dimensional schematic diagram of the self-cleaning vibrating trommel screen with adjustable inclination as shown in the figure, the trommel screen is a cylinder surrounded by sieve plates 7, and the feeding end of the cylinder is octagonal prism-shaped, and the discharging end is cylindrical. Both ends of the cylinder are provided with flanges connected thereto, and each is connected with an annular friction ring 14 through fasteners provided on the flanges. Eight angle-steel-shaped outer scraper brackets are intermittently arranged on the outer peripheral surface of the drum, and the right-angled sides parallel to the tangent line of the drum are respectively fixed on the two flanges ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com