Machine for labelling containers and attaching shrink sleeves to containers and method for the same

A shrink sleeve and labeling technology, which is applied to equipment for labeling containers and for installing shrink sleeves on containers and in the field, can solve the problems of inability to handle high machine power, consumption, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

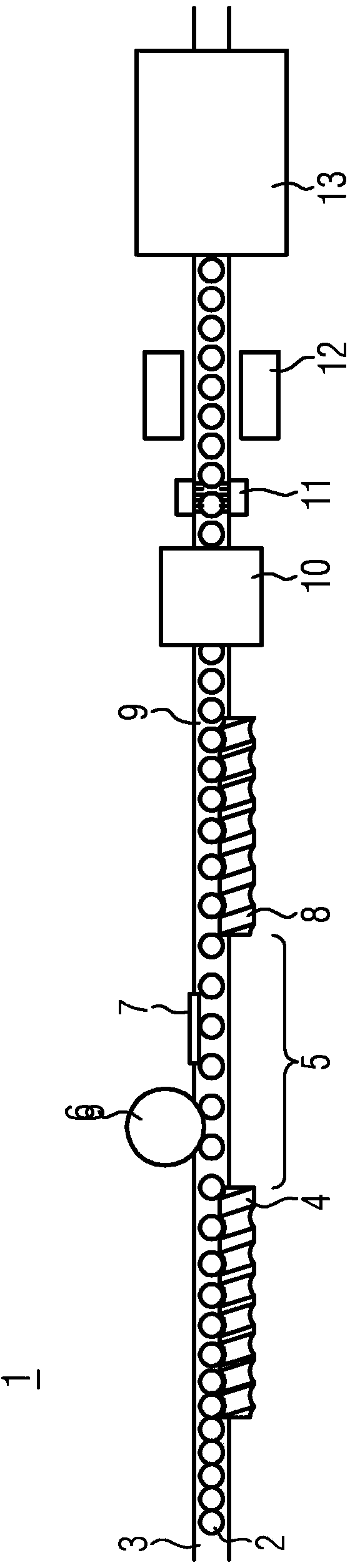

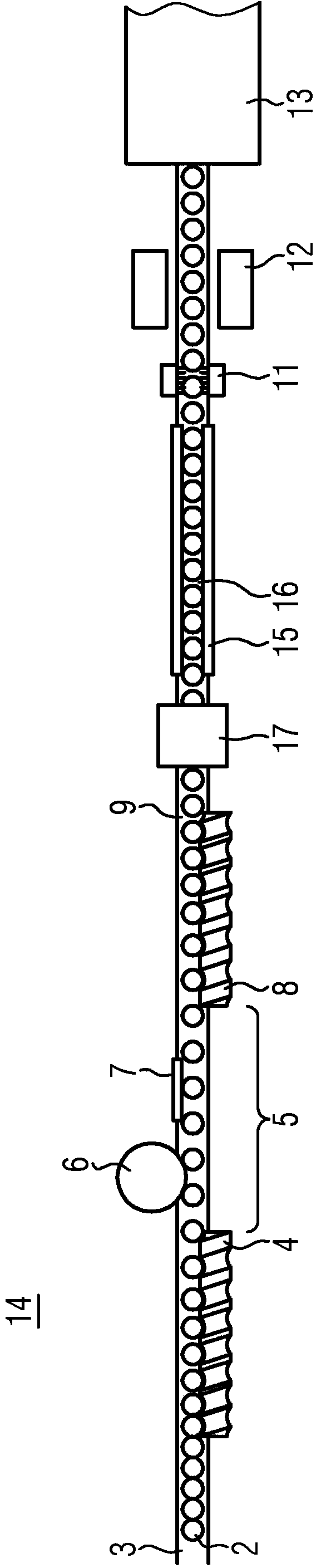

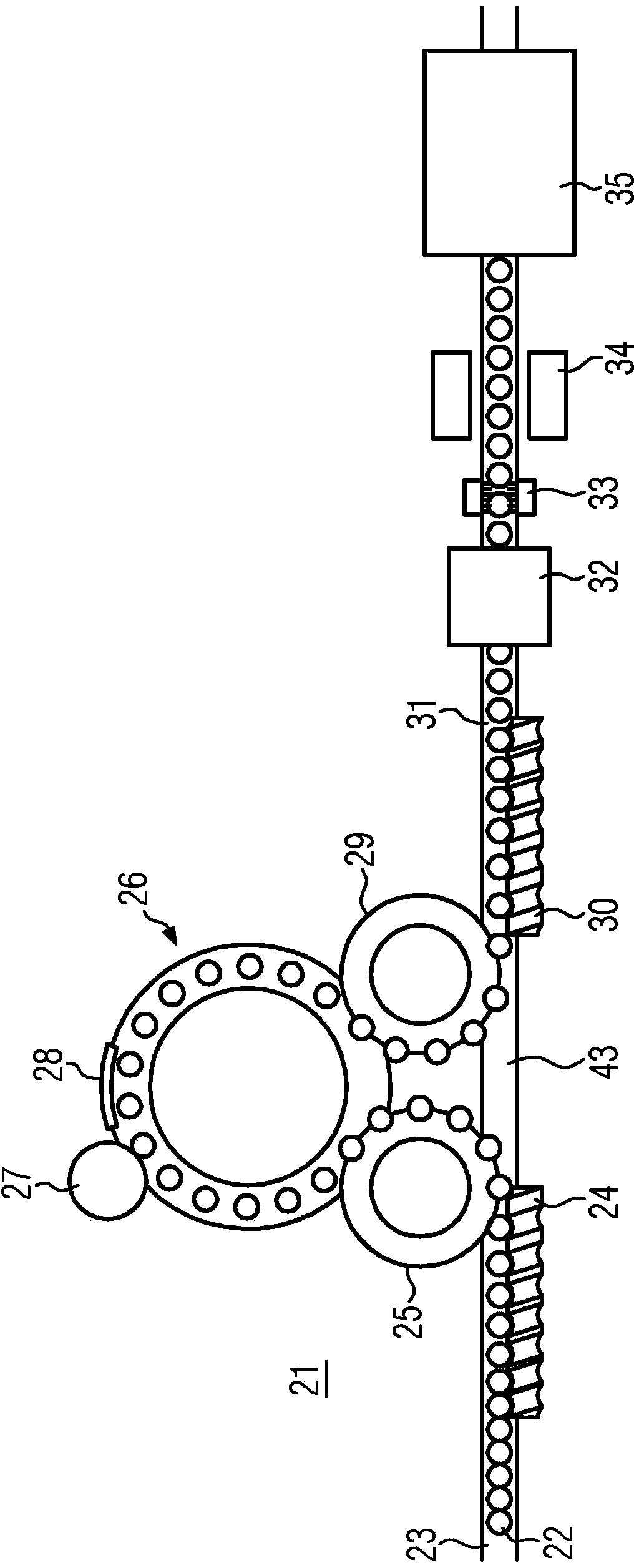

[0046] figure 1 A first embodiment of a device 1 for labeling and for applying shrink sleeves to containers 2 is shown.

[0047] The containers 2 are transported by means of an upstream conveyor belt 3 moving at an upstream speed. The flow of containers, in which the containers 2 are conveyed without spacing by the upstream conveyor belt 3 to the upstream indexing screw 4 , is spread out by the indexing screw 4 , so that a space is created between the containers 2 corresponding to the labeling machine, which is then implemented in a straight line 5 for the first separation pitch. This means that the upstream indexing screw 4 is preferably designed such that the pitch of its last flight corresponds to the first separation distance of the labeling machine 5 . The containers 2 to be labeled can thus be conveyed to the labeling machine 5 by means of the upstream indexing screw 4 at a predefined distance which is necessary for the labeling to take place.

[0048] A labeling stat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com