Rabbit cage feeding device and automatic control system thereof

A feeding device and rabbit cage technology, applied in the field of rabbit breeding, can solve the problems of time-consuming cleaning, large pulling resistance, overflow of feed, etc., and achieve the effect of convenient cleaning and cleaning, convenient adjustment and operation, and avoiding stress response

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0050] The present invention will be further described below in conjunction with the accompanying drawings.

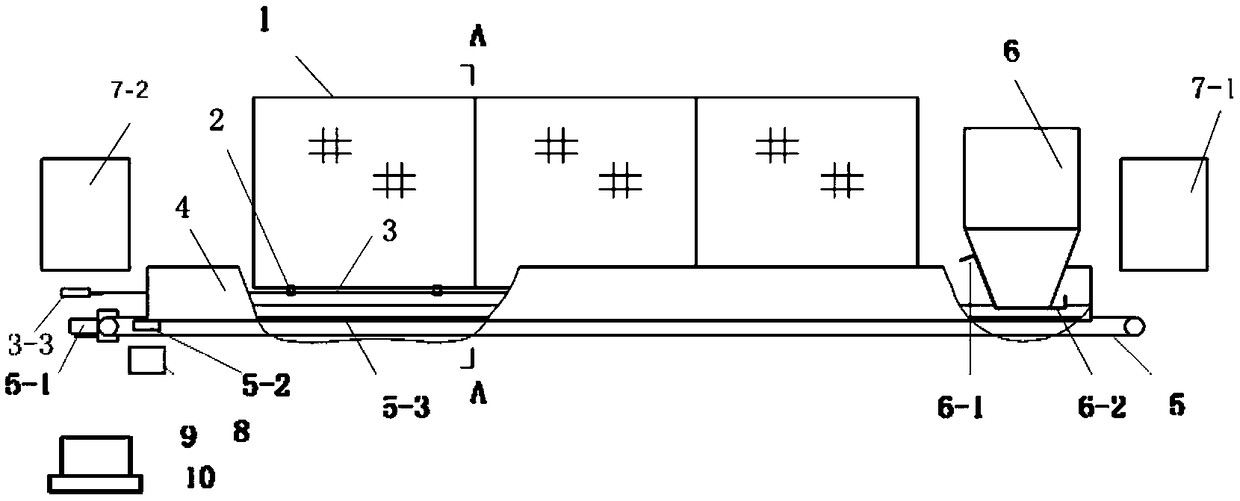

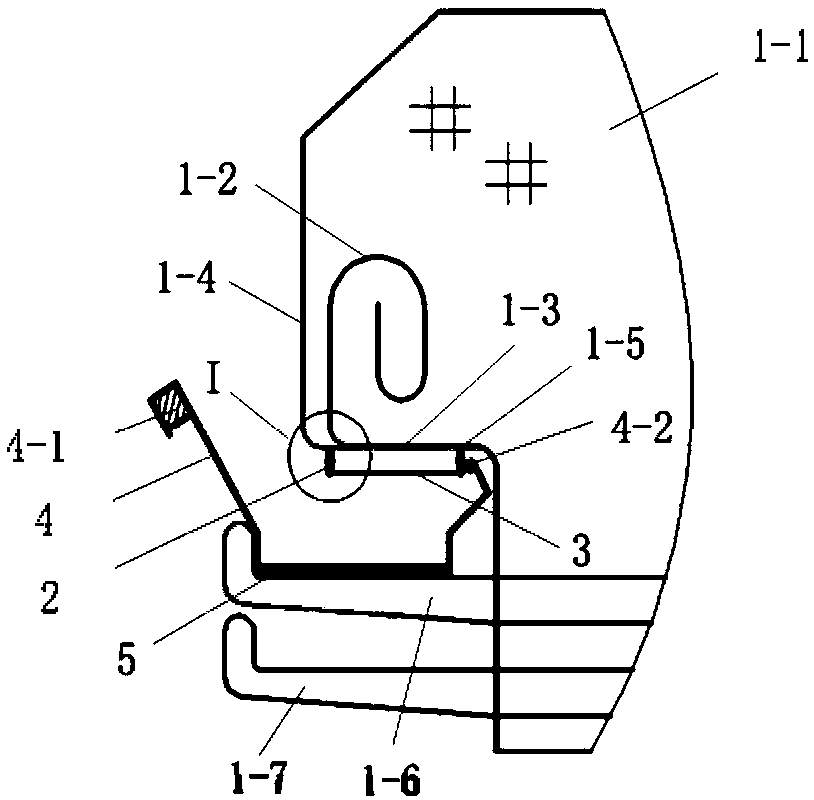

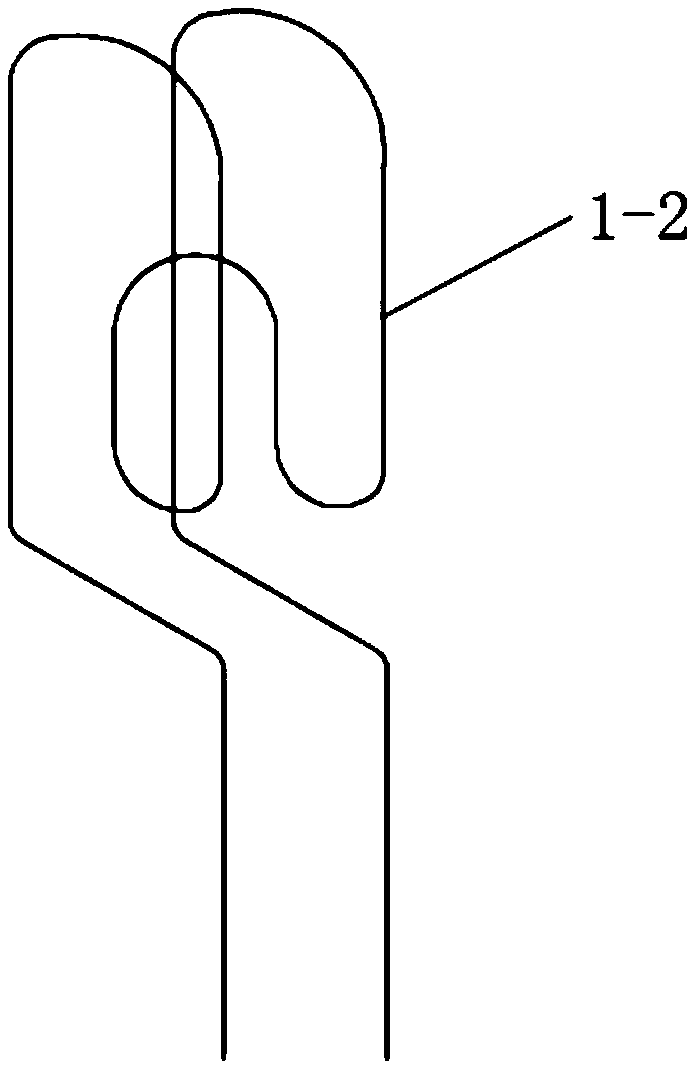

[0051] Such as figure 1 and figure 2 As shown, the embodiment of the present invention is a belt feeding system for a single-layer rabbit cage row, comprising: rabbit cage row 1, trough door switch mechanism 2, trough door 3, trough 4, feeding belt 5, hopper 6 and central control system 7; wherein the rabbit cage column 1 is composed of several rabbit cage units 1-1 in series, the trough door 3 is hoisted below the feeding platform of the rabbit cage unit 1-1 by the trough door switch mechanism 2, Groove 4 is positioned at the just below of manger door 3 and is fixed on the manger bracket 1-6 that stretches out on the wall of both sides of rabbit cage unit 1-1, and feeding belt 5 passes manger 4 and its reverse side is attached to the manger. The groove bottom surface of groove 4 moves in one direction.

[0052] Such as image 3 Shown is the embodiment that the ra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com