Winding buffering mechanism and winching device

A technology of buffer mechanism and hoisting device, applied in the direction of hoisting device, spring mechanism, etc., can solve the problems of unfavorable protection of self-bending wind grille, unfavorable protection of self and bending wind grille, etc., to achieve safe use and avoid damage to equipment Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

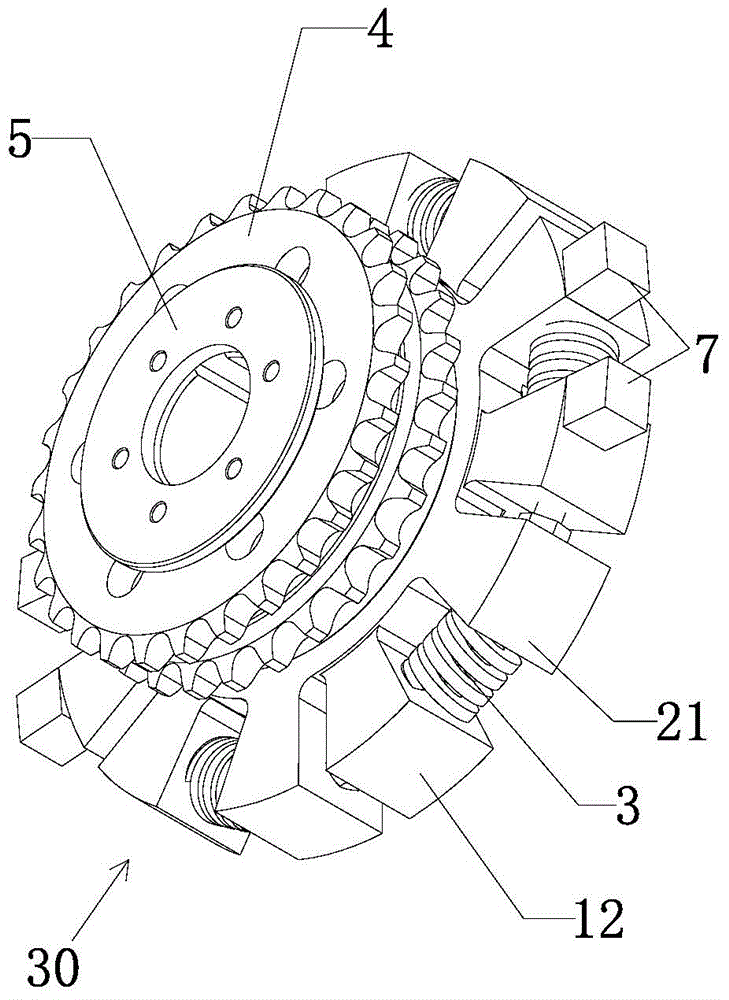

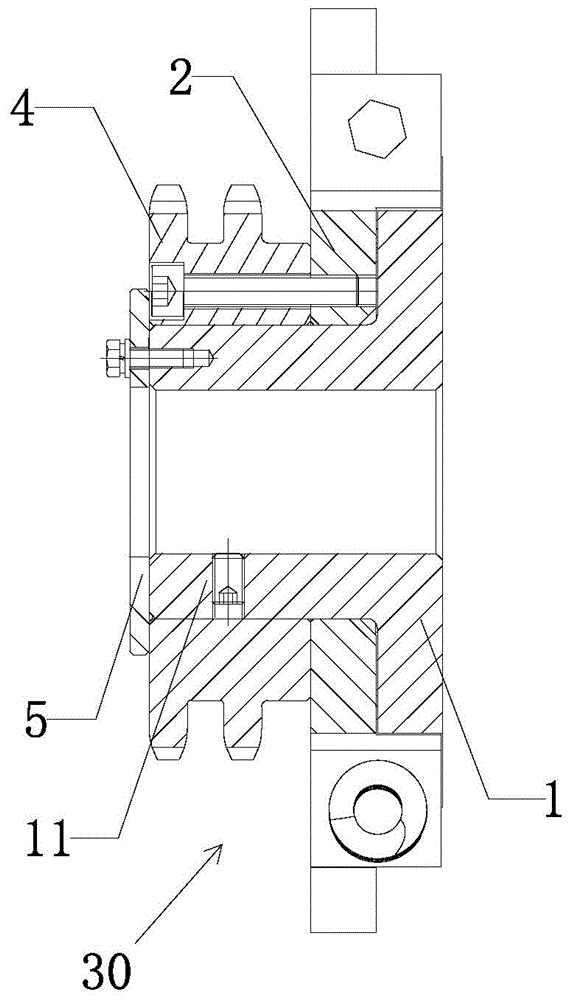

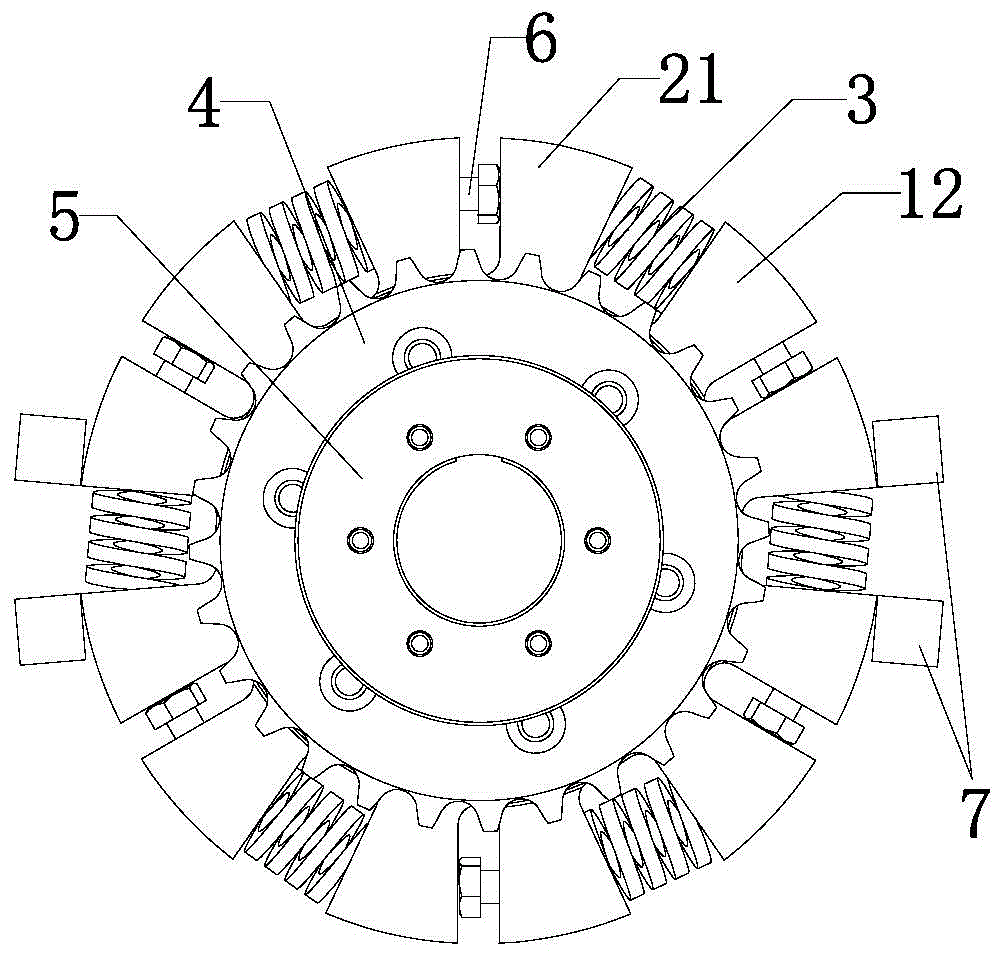

[0028] Such as Figure 1 to Figure 5 As shown, the hoisting buffer mechanism 30 includes a first transmission disc 1, a second transmission disc 2, six buffer elastic members 3, a driven sprocket 4 and an end cover 5, and the first transmission disc 1 is provided with a center extending The central axis 11 and six first moment arms 12 distributed along the periphery, the second transmission disc 2 is provided with six second moment arms 21 corresponding to the first moment arms 12 distributed along the periphery, the second transmission disc 2 Rotatably sheathed on the central shaft 11, the six first moment arms 12 and the six second moment arms 21 intersect each other, and the corresponding first moment arms 12 and the second moment arms 21 are adjacent in position. A cushioning elastic member 3 is provided in the intersecting space between the first moment arm 12 and the second moment arm 21, and the two ends of the buffer elastic member 3 abut against the corresponding firs...

Embodiment 2

[0034] combine Figure 1 to Figure 7, the hoisting device, including the drive motor 10, the fixed base 20 and the hoisting buffer mechanism 30; the fixed base 20 is provided with a rotatable first hoisting shaft 201, a second hoisting shaft 202 and a drive shaft 203, the first The hoisting shaft 201 is connected to the first connecting piece 40, the second hoisting shaft 202 is connected to the second connecting piece 41, and the transmission shaft 203 is connected to the first hoisting shaft 201 and the second hoisting shaft 202; the hoisting buffer mechanism 30 includes a first transmission disc 1, a second transmission disc 2, six buffer elastic members 3, a driven sprocket 4 and an end cover 5. The first transmission disc 1 is provided with a central axis 11 extending along the center and distributed along the periphery. Six first moment arms 12, the second transmission disc 2 is provided with six second moment arms 21 corresponding to the first moment arms 12 distributed...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com