A kind of composite material with photochromic performance and preparation method thereof

A technology of photochromic and composite materials, applied in the direction of color-changing fluorescent materials, chemical instruments and methods, etc., can solve the problems of unstable quality of composite materials, insensitive photochromic performance, and high application environment requirements, and achieve excellent photochromic Performance, wide application potential, effect of short process cycles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

[0031] Specific Embodiment 1: This embodiment is a kind of composite material with photochromic performance, which consists of 0.02 to 1.5 parts by weight of molybdenum compound with photochromic performance, 10 to 35 parts of solvent, 6 to 20 parts It is prepared by curing agent and 50-150 parts of resin matrix.

[0032] The advantage of this specific embodiment:

[0033] 1. The composite material with photochromic properties prepared in this specific embodiment uses simple and easy-to-obtain raw materials, low cost, and little environmental pollution;

[0034] 2. The technical process of the composite material with photochromic properties prepared in this specific embodiment is simple, easy to operate, and the equipment used are conventional instruments in this field, the process cycle is short, and the requirements for the process environment are relatively low;

[0035] Three, the quality of the composite material with photochromic performance prepared by this specific em...

specific Embodiment approach 2

[0039] Embodiment 2: The difference between this embodiment and Embodiment 1 is that the resin matrix is epoxy resin E51, epoxy resin TDE-85 or polyester resin. Other steps are the same as in the first embodiment.

specific Embodiment approach 3

[0040] Embodiment 3: This embodiment differs from Embodiment 1 or Embodiment 2 in that: the solvent is 1-methyl-2-pyrrolidone or dimethylformamide. Other steps are the same as those in Embodiment 1 or 2.

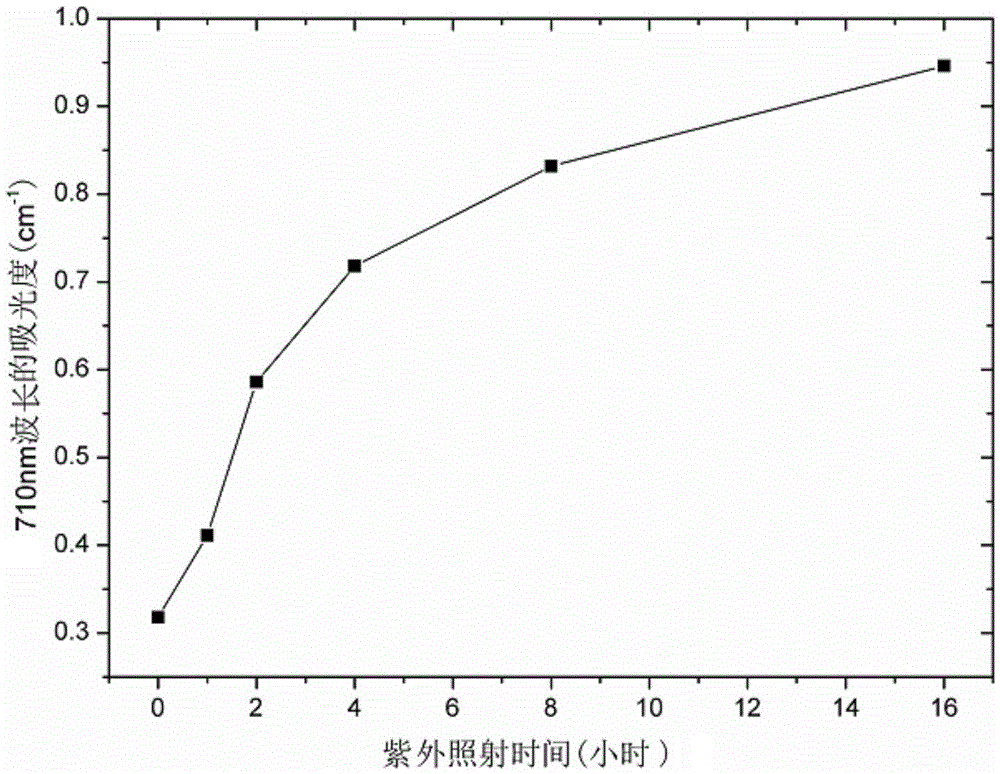

PUM

| Property | Measurement | Unit |

|---|---|---|

| absorbance | aaaaa | aaaaa |

| absorbance | aaaaa | aaaaa |

| absorbance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com