High-activity photochromic bismuth oxychloride/calcium alginate photocatalytic hydrogel microbead and preparation method thereof

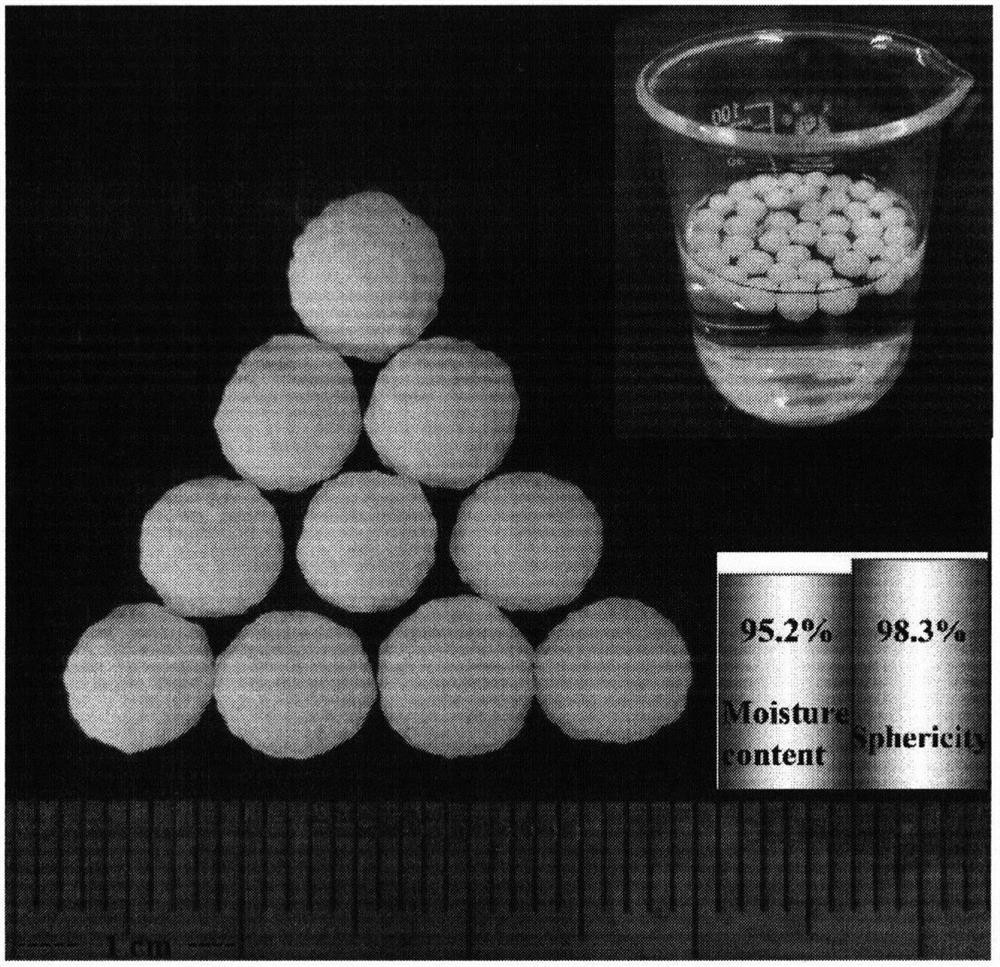

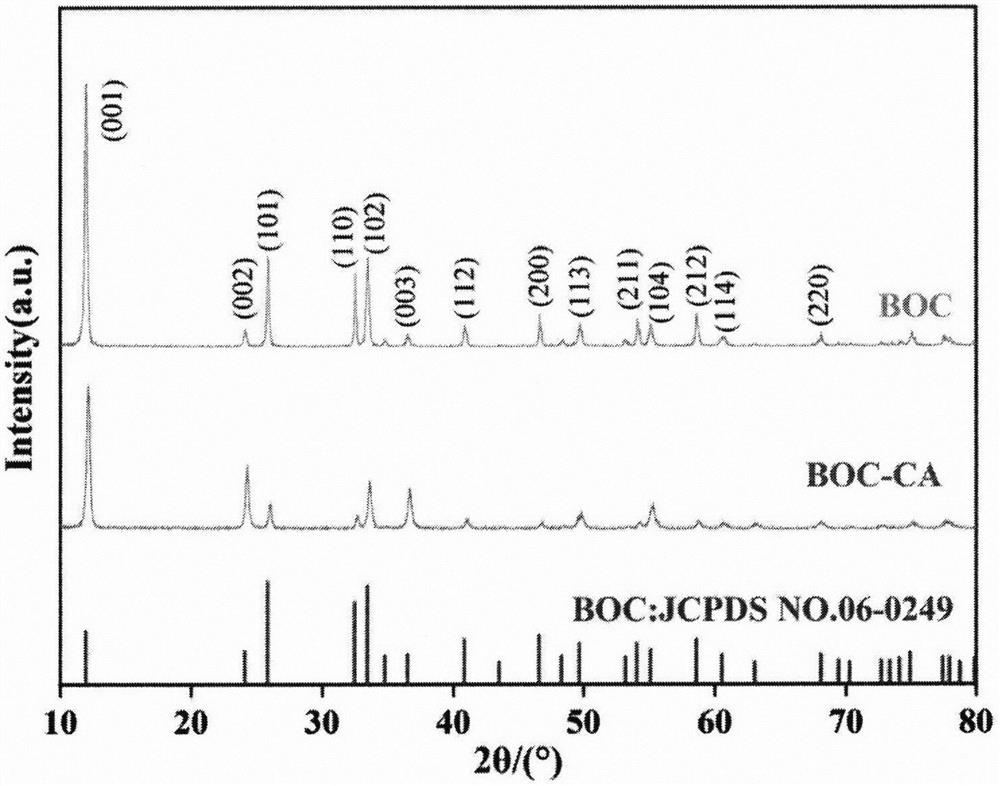

A technology of hydrogel microbeads and photochromism, applied in chemical instruments and methods, light water/sewage treatment, physical/chemical process catalysts, etc., can solve problems such as difficult recycling, difficult reuse, and large losses. Achieve the effects of good photochromic properties, good spherical shape, and enhanced photocatalytic efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] (1) Preparation of Ca-BOC-SA mixed colloids. 1g of CaCO 3 Dissolve 0.4g of BiOCl powder in deionized water, stir to prepare Ca-BOC mixed suspension after ultrasonic dispersion, then add 0.4g of SA powder into Ca-BOC mixed suspension, stir magnetically for 1h until completely dissolved, and prepare into Ca-BOC-SA mixed colloid.

[0023] (2) Prepare a mixed solution of calcium chloride and glacial acetic acid. Weigh 1g CaCl 2 In a 100mL beaker, add 5mL of deionized water, stir the glass rod until it is completely dissolved, then add 45mL of glacial acetic acid to prepare a mixed solution of calcium chloride and glacial acetic acid with a volume ratio of 9:1.

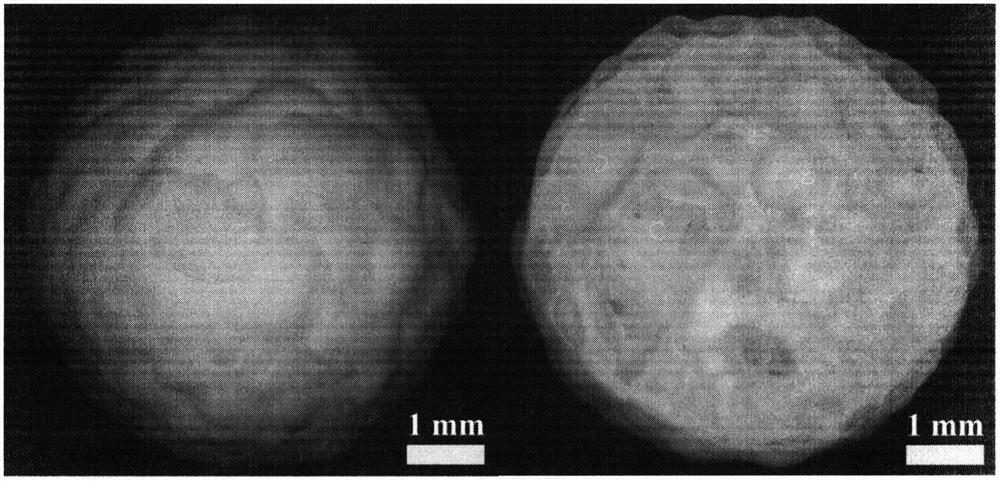

[0024] (3) To prepare BOC-CA hydrogel, drop the Ca-BOC-SA mixed colloid into the mixed solution of calcium chloride and glacial acetic acid from a height of about 25 cm on the liquid surface with a dropper with a diameter of about 5 cm, and use it after reacting for 2 hours. Soak in deionized water for 48 hours,...

Embodiment 2

[0032] (1) Preparation of Ca-BOC-SA mixed colloids. 1g of CaCO 3 Dissolve 0.06g of BiOCl powder in deionized water, stir after ultrasonic dispersion to prepare Ca-BOC mixed suspension, then add 0.4g of SA powder into Ca-BOC mixed suspension, stir magnetically for 1h until completely dissolved, and prepare into Ca-BOC-SA mixed colloid.

[0033] (2) Prepare a mixed solution of calcium chloride and glacial acetic acid. Weigh 1g CaCl 2 In a 100mL beaker, add 5mL of deionized water, stir the glass rod until it is completely dissolved, then add 45mL of glacial acetic acid to prepare a mixed solution of calcium chloride and glacial acetic acid with a volume ratio of 9:1.

[0034] (3) To prepare BOC-CA hydrogel, drop the Ca-BOC-SA mixed colloid into the mixed solution of calcium chloride and glacial acetic acid from a height of about 25 cm on the liquid surface with a dropper with a diameter of about 5 cm, and use it after reacting for 2 hours. Soak in deionized water for 48 hours...

Embodiment 3

[0038] (1) Preparation of Ca-BOC-SA mixed colloids. 1g of CaCO 3 Dissolve 0.2g of BiOCl powder in deionized water, stir to prepare Ca-BOC mixed suspension after ultrasonic dispersion, then add 0.4g of SA powder into Ca-BOC mixed suspension, stir magnetically for 1h until completely dissolved, and prepare into Ca-BOC-SA mixed colloid.

[0039] (2) Prepare a mixed solution of calcium chloride and glacial acetic acid. Weigh 1g CaCl 2 In a 100mL beaker, add 5mL of deionized water, stir the glass rod until it is completely dissolved, then add 45mL of glacial acetic acid to prepare a mixed solution of calcium chloride and glacial acetic acid with a volume ratio of 9:1.

[0040] (3) To prepare BOC-CA hydrogel, drop the Ca-BOC-SA mixed colloid into the mixed solution of calcium chloride and glacial acetic acid from a height of about 25 cm on the liquid surface with a dropper with a diameter of about 5 cm, and use it after reacting for 2 hours. Soak in deionized water for 48 hours,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com