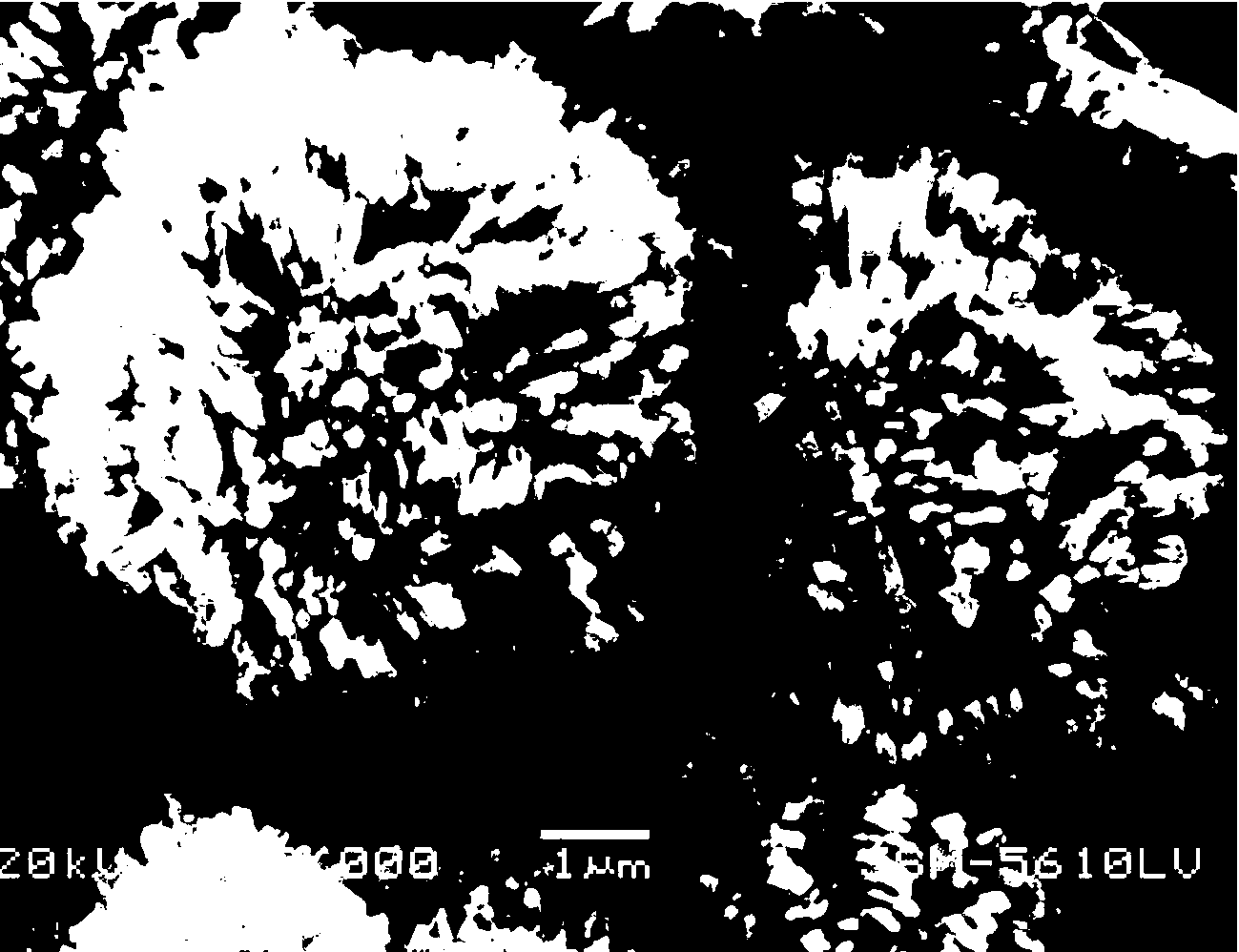

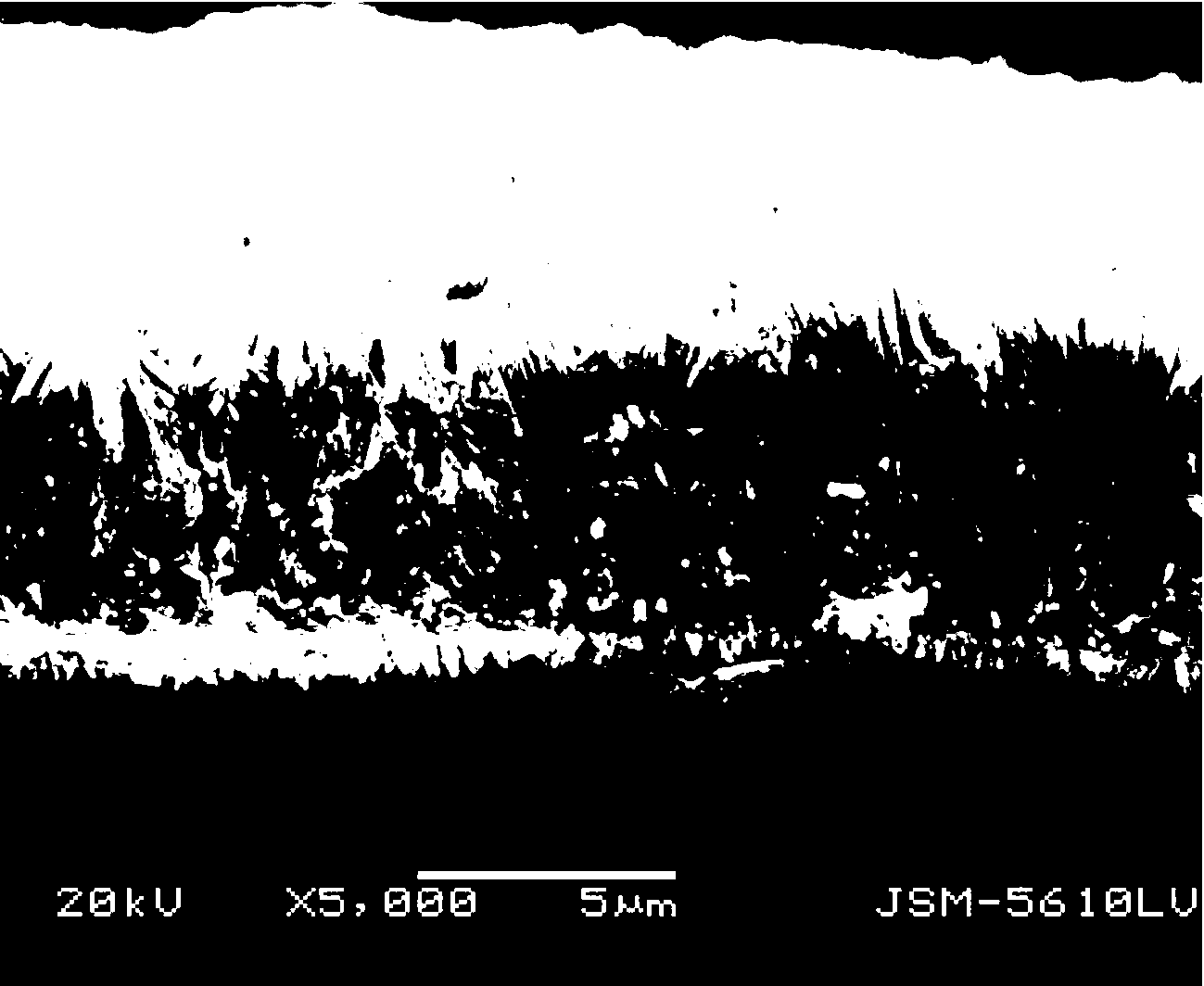

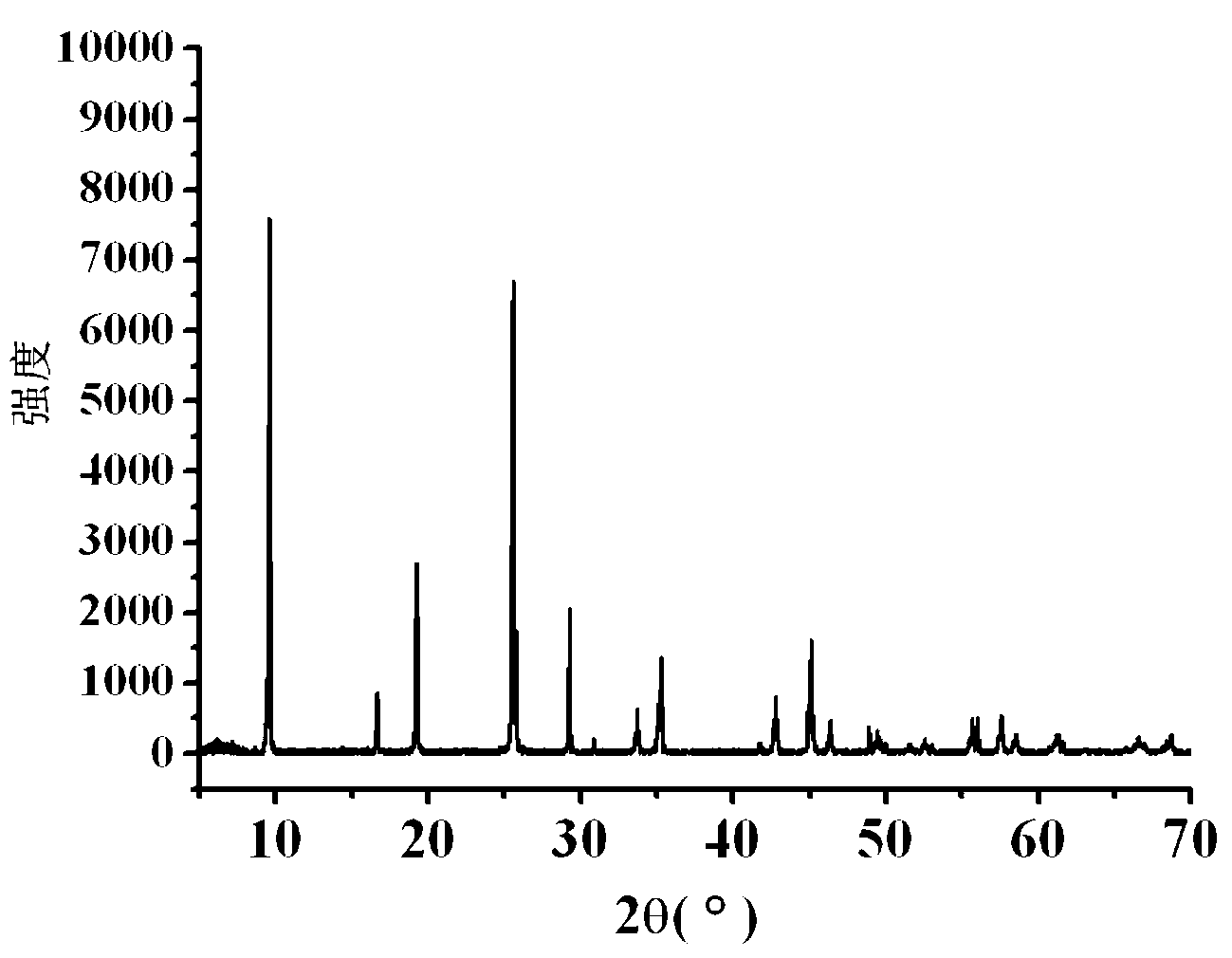

Preparation method of thorn-ball photochromic MoO3 thin film

A photochromic, thorn spherical technology, applied in the direction of molybdenum oxide/molybdenum hydroxide, etc., can solve the problem of the film being insensitive to excitation light, and achieve the effect of good photochromic effect, excitation light sensitivity, and large light absorption area.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] A spiny spherical photochromic MoO 3 The preparation method of thin film, it comprises the following steps:

[0034] (1) Prepare 0.16 mol / L Na 2 MoO 4 Solution 50 mL;

[0035] (2) Press Na 2 MoO 4 The volume ratio of the solution to the interfering agent formaldehyde solution is 50.0:2. With the magnetic stirrer stirring at a speed of 400 r / min, the temperature is controlled at 10°C, and 2 mL is added dropwise at a speed of 50 seconds per drop with a mass fraction of 37 % formaldehyde solution in Na 2 MoO 4 In the solution, adjust the pH of the solution to 1.0 with concentrated hydrochloric acid with a concentration of 37% by mass, and stir and homogenize at 400 r / min at 10°C for 4 h in the dark. ;

[0036] (3) Move the homogenized reaction solution into a reaction vessel, put it on a cleaned ITO conductive glass substrate, and react in hydrothermal reaction at 120°C for 48 h;

[0037] (4) After the hydrothermal reaction is over, after the reaction system is co...

Embodiment 2

[0041] A spiny spherical photochromic MoO 3 The preparation method of thin film, it comprises the following steps:

[0042] (1) Prepare 50 mL of 0.16 mol / L potassium molybdate solution;

[0043] (2) According to the volume ratio of potassium molybdate solution and interfering agent formaldehyde solution of 50.0:1, under the magnetic stirrer stirring at a speed of 200 r / min, the temperature is controlled at 5°C, and the speed is 30 seconds per drop drop by drop Add 1 mL of formaldehyde solution with a mass fraction of 37% to the potassium molybdate solution, adjust the pH of the solution to 0.8 with concentrated hydrochloric acid with a concentration of 38% by mass, stir and homogenize at 5°C and avoid light at 200 r / min for 3 h ;

[0044] (3) Move the homogenized reaction solution into a reaction vessel, put it on a cleaned FTO conductive glass substrate, and react in hydrothermal reaction at 100°C for 24 h;

[0045] (4) After the hydrothermal reaction is over, after the re...

Embodiment 3

[0048] A spiny spherical photochromic MoO 3 The preparation method of thin film, it comprises the following steps:

[0049] (1) Prepare 50 mL of 0.16 mol / L potassium molybdate solution;

[0050] (2) According to the volume ratio of potassium molybdate solution and interfering agent formaldehyde solution of 50.0:3, under the magnetic stirrer stirring at a speed of 600 r / min, the temperature is controlled at 15°C, and the speed is 60 seconds per drop drop by drop Add 3 mL of formaldehyde solution with a mass fraction of 37% to the potassium molybdate solution, adjust the pH of the solution to 1.5 with concentrated hydrochloric acid with a concentration of 38% by mass, stir and homogenize at 15°C and avoid light at 600 r / min for 6 h ;

[0051] (3) Move the homogenized reaction solution into a reaction vessel, put it on a cleaned FTO conductive glass substrate, and react in hydrothermal reaction at 140°C for 60 h;

[0052] (4) After the hydrothermal reaction is over, after the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com