Patents

Literature

63results about How to "Increase light absorption area" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Solar-grade silicon wafer being cut by diamond wire and cutting method thereof

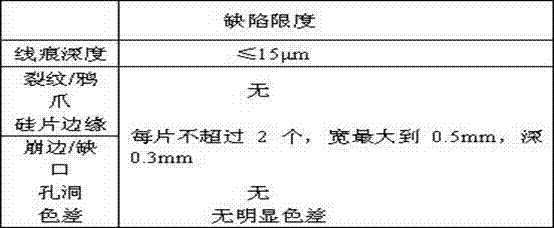

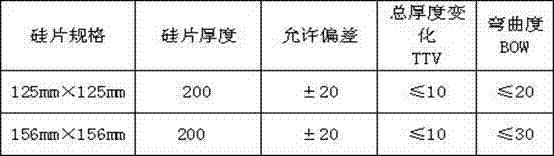

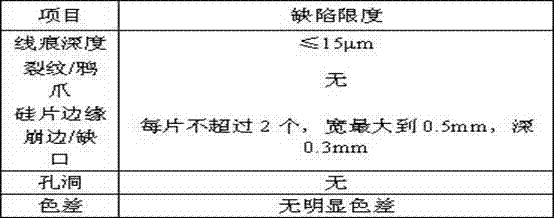

InactiveCN102390094AFast cutting speedSave silicon resourcesFine working devicesDiamond cuttingMicrometer

The invention discloses a solar-grade silicon wafer being cut by a diamond wire and a cutting method thereof. A mono-crystalline silicon square rod is cut by a diamond wire. The cutting method comprises the following steps that: the mono-crystalline silicon square rod which is formed by squaring, grinding and sharpening a mono-crystalline silicon circular rod, the mono-crystalline silicon square rod is fixed on a resin strip through an adhesive bar, the resin strip is fixed on an adhesive plate, then the adhesive plate and the mono-crystalline silicon square rod are collectively placed into a working cabin to be preheated, cutting liquid is circulated in the working cabin to work, then the diamond cutting is performed, the cut mono-crystalline silicon wafer is inversely arranged on a degumming device to degum, and the mono-crystalline silicon wafer is washed by ultrasonic and then is centrifugally dehydrated. Due to the adoption of the cutting method, the photoelectric conversion efficiency and the cutting efficiency of the mono-crystalline silicon wafer can be improved, a silicon wafer with the thickness of 140 to 200 micrometers can be produced, the qualification rate of the product can reach more than 98 percent; and silicon powder is recyclable, so valuable silicon resource can be saved, and the environment-friendly production can be really realized during the production process.

Owner:江西金葵能源科技有限公司

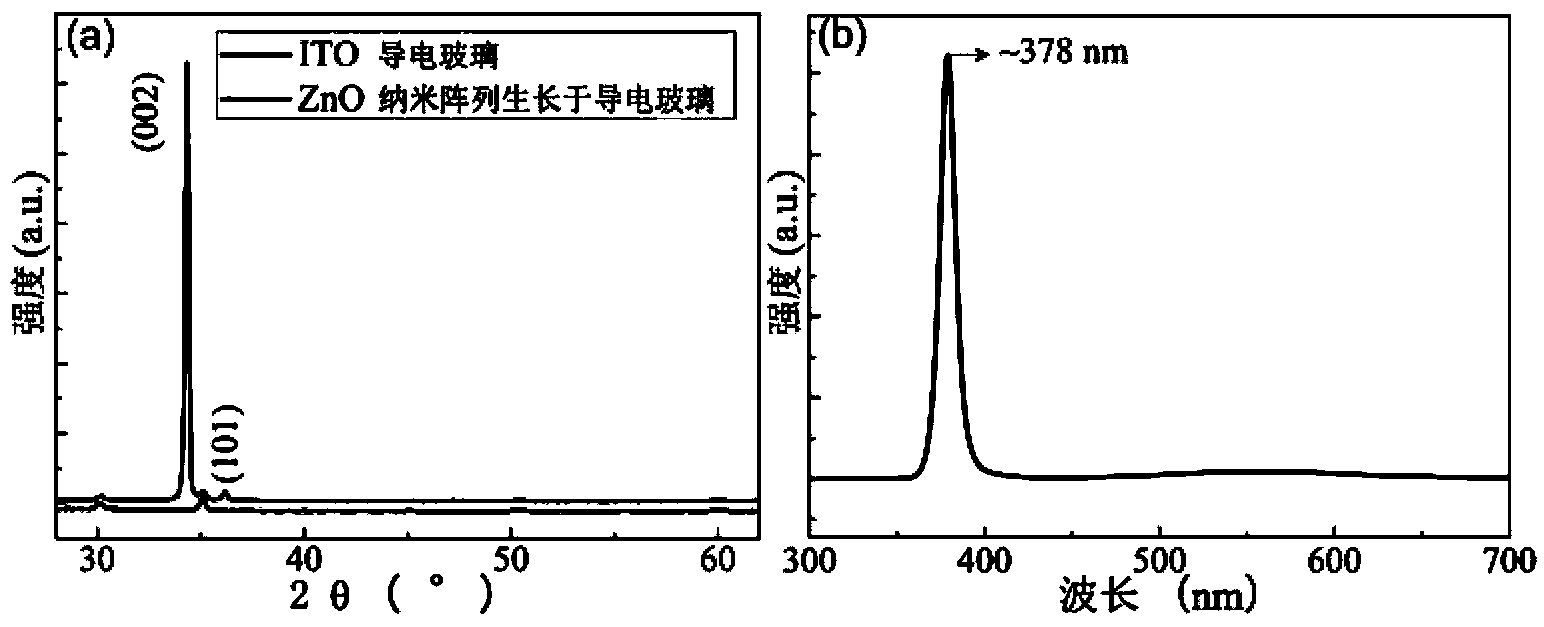

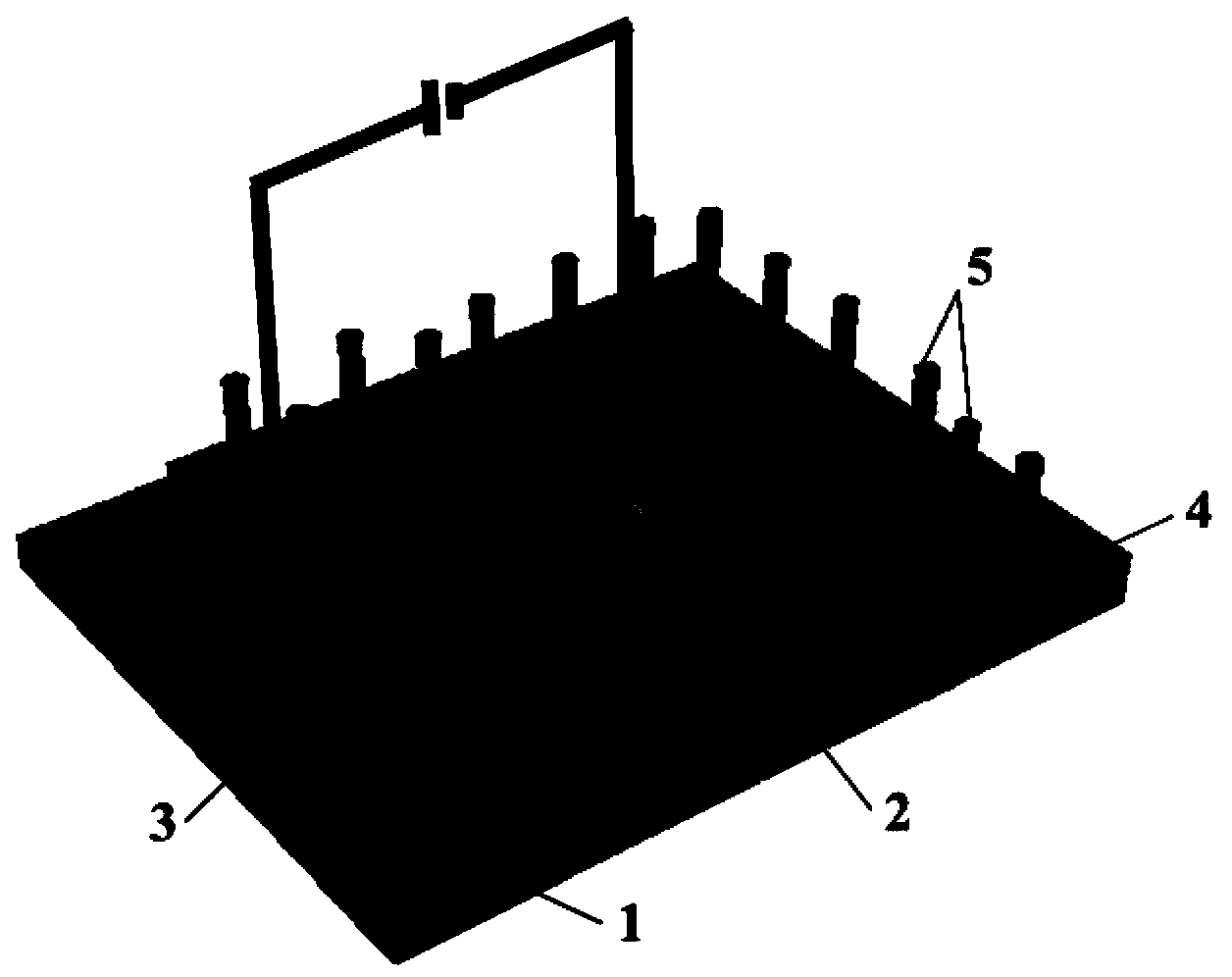

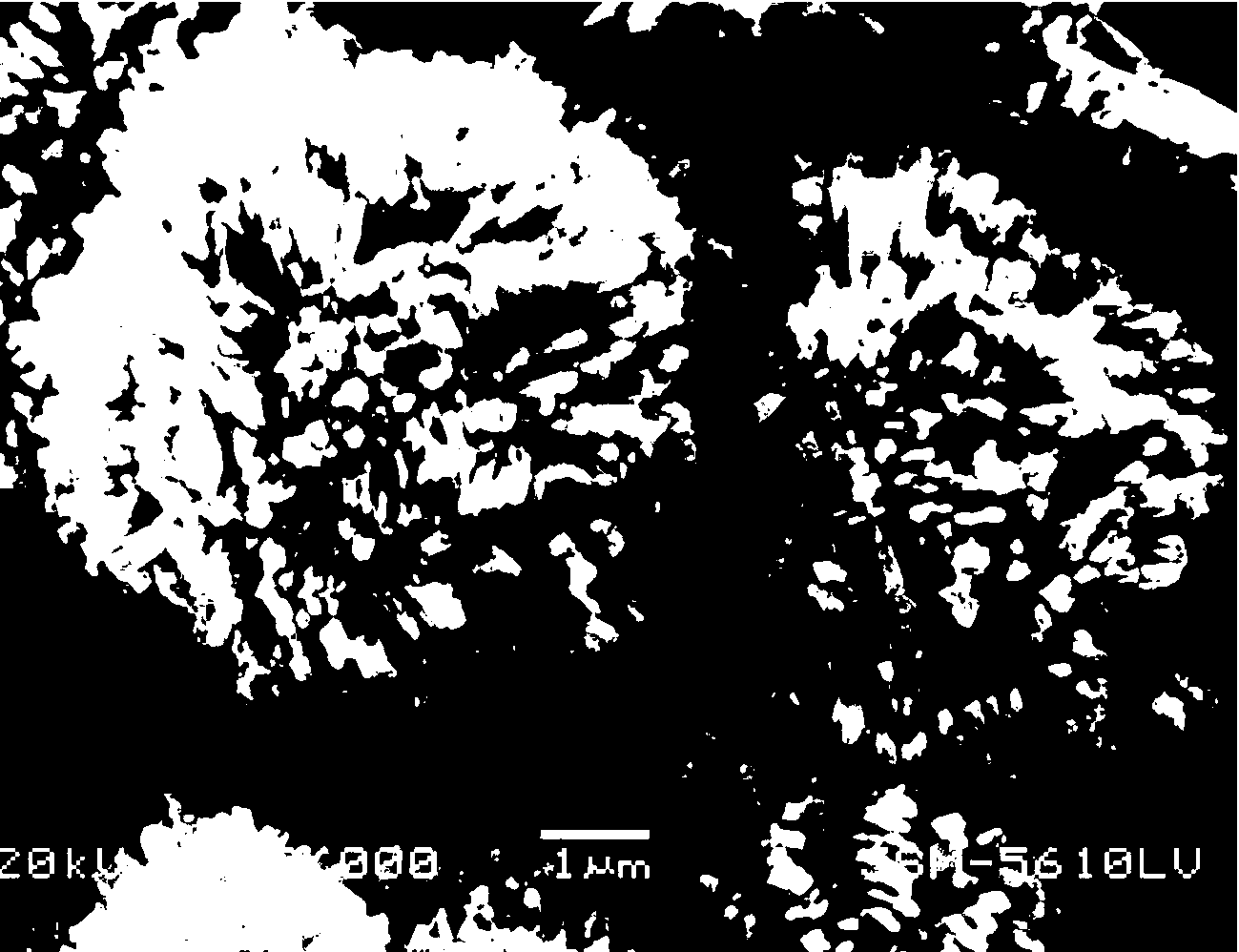

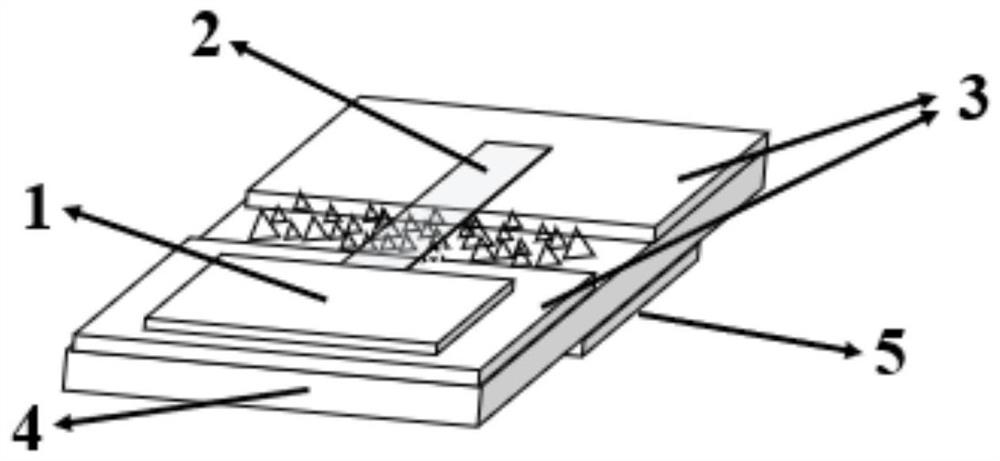

ZnO nanometer array ultraviolet detector and manufacturing method thereof

ActiveCN103441154ASimplify the build processImprove collection efficiencyFinal product manufactureSemiconductor devicesUltraviolet detectorsThin membrane

The invention discloses a ZnO nanometer array ultraviolet detector and a manufacturing method of the ZnO nanometer array ultraviolet detector. The structure of the ultraviolet detector is of a metal-semiconductor-metal contact type. The ultraviolet detector sequentially comprises a substrate of ITO conductive glass or FTO conductive glass, a ZnO film, an electrode at the other end and a ZnO nanometer array from bottom to top. The substrate is an electrode at one end; the ZnO film covers the substrate, the electrode at the other end is located in the middle position of the ZnO film, and the ZnO nanometer array is arranged on the periphery of the electrode at the other end; the area of the electrode at the other end is 10%-12% of the total area of the substrate. The manufacturing method comprises the following steps: firstly, performing sputtering on the substrate through magnetic control to produce a layer of ZnO film, secondly, installing electrodes on the ZnO film and leading out one end of a wire, thirdly, covering the electrodes with PDMS protection layers, fourthly, developing the ZnO nanometer array through a hydrothermal method, finally, scraping off part of ZnO at the edge on one side of a sample so that the substrate of the conductive glass can be exposed, and leading out the other end of the wire. Thus, the ultraviolet detector is obtained. The ultraviolet detector and the manufacturing method of the ultraviolet detector have the advantages of being simple in manufacturing process, easy to operate, low in cost, high in device sensitivity, stable in performance and the like.

Owner:UNIV OF SCI & TECH BEIJING

Preparation method of seawater desalination material based on polyurethane foam

ActiveCN110511558AImprove water absorptionRich porosityGeneral water supply conservationSeawater treatmentPolyvinyl alcoholPhotothermal conversion

The invention relates to a preparation method of a material, specifically to a preparation method of a seawater desalination material based on polyurethane foam. The invention aims to solve the problem of low desalination efficiency of seawater desalination material prepared by utilizing conventional photothermal conversion methods. The preparation method comprises the following steps: 1, preparing an ammonium persulfate solution and an aniline solution; 2, preparing polyaniline powder; 3, preparing a polyaniline solution; 4, preparing a polyvinyl alcohol solution; 5, preparing a crude productof the seawater desalination material based on the polyurethane foam; and 6, carrying out optimization treatment to obtain the seawater desalination material based on the polyurethane foam. The prepared seawater desalination material can fully utilize the pore diameter structure of a polyurethane foam material and the nano-channel of a polyvinyl alcohol gel, effectively reduces latent heat of evaporation of water, and greatly improves sea water desalination efficiency. The seawater desalination material has a high seawater evaporation rate (2.0 kg / m<2> / h) and high desalination efficiency (99.9%), which is increased by 25% compared with traditional photothermal conversion seawater desalination materials.

Owner:HARBIN INST OF TECH AT WEIHAI +1

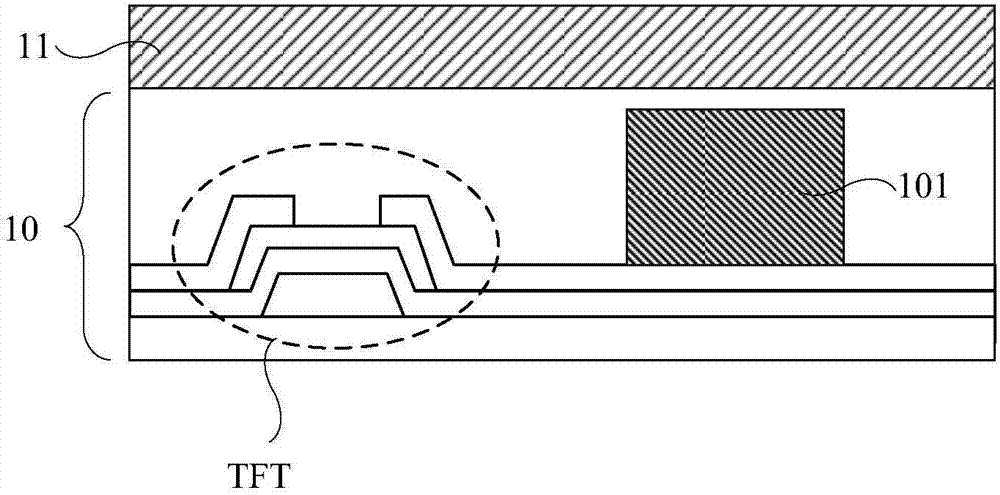

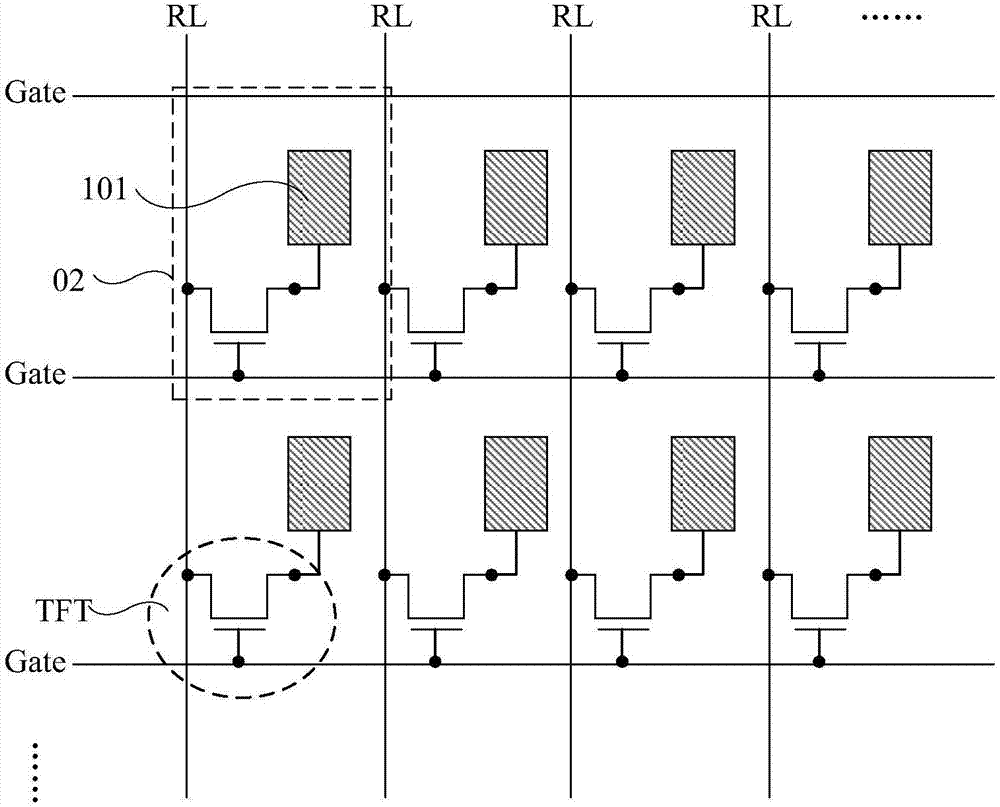

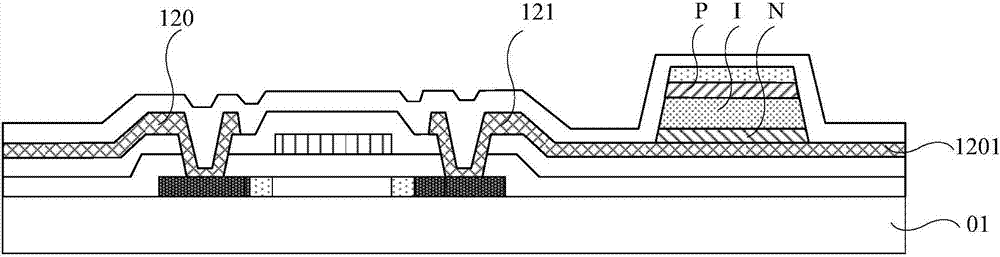

Array substrate, manufacturing method of array substrate, flat panel detector and imaging device

ActiveCN107104108AUniform electrical propertiesReduce the chance of badTransistorSolid-state devicesCorrosion resistantEngineering

The invention provides an array substrate, a manufacturing method of the array substrate, a flat panel detector and an imaging device, and relates to the field of photoelectric technology. The influence of manufacturing process of a photoelectric converter on the TFT performance can be reduced. The array substrate comprises a substrate, a plurality of low-temperature polycrystalline silicon TFT arranged on the substrate in an array, and a photoelectric converter connected with source electrodes or drain electrodes of the TFT, wherein the source electrode or the drain electrode of each TFT comprises a first conducting layer close to one side of the photoelectric converter, and the material constituting the first conducting layer is corrosion resistant in a composition process of the photoelectric converter. The array substrate is used for preparing the flat panel detector.

Owner:BOE TECH GRP CO LTD +1

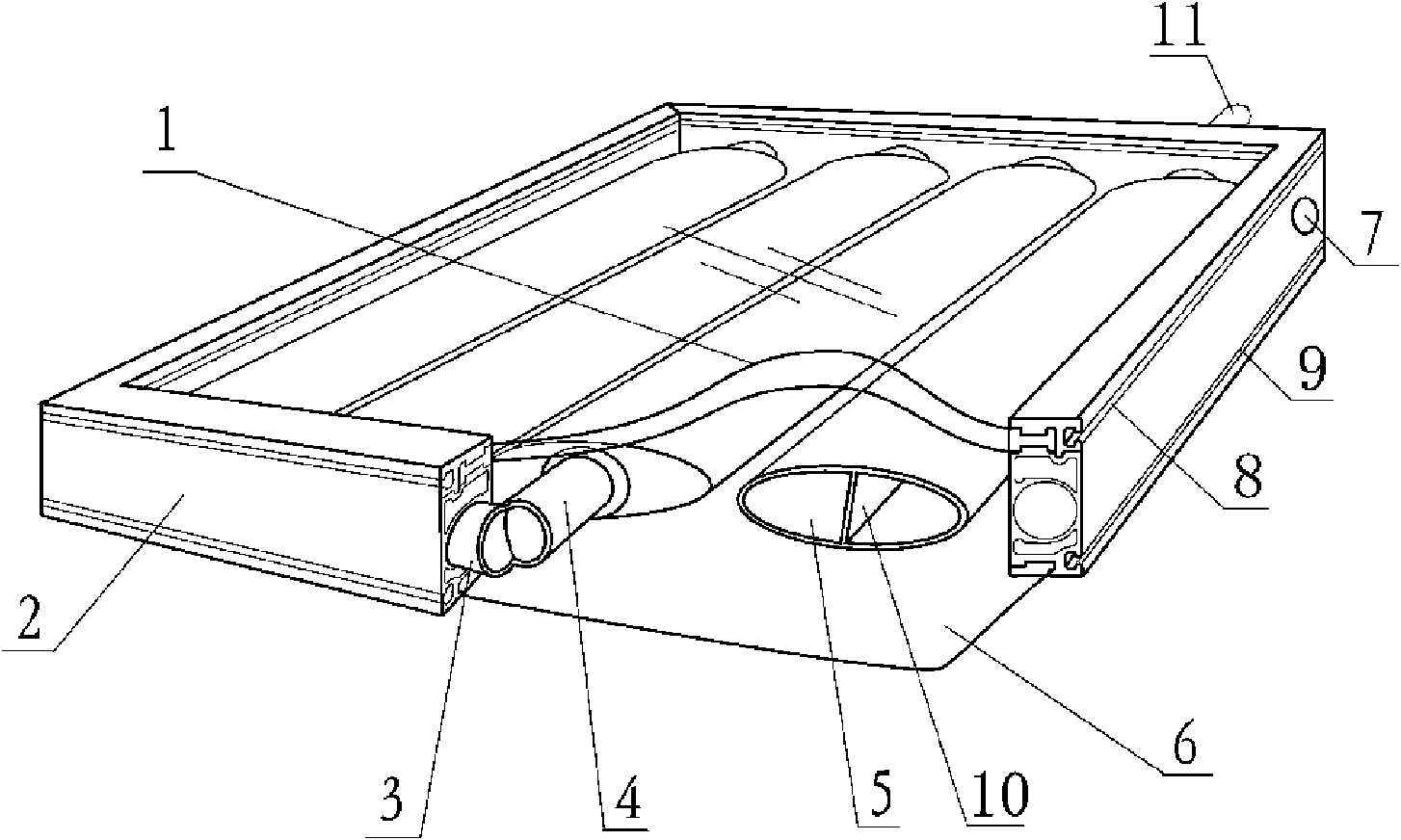

Aluminum-plastic solar heat collector

InactiveCN101666552AIncrease light absorption areaImprove heat collection efficiencySolar heating energySolar heat devicesPolycarbonateAluminium foil

The invention relates to an aluminum-plastic solar heat collector. A shell is enclosed into a flat box body by a hollow frame, a transparent cover plate positioned at a light-receiving surface and connected with the hollow frame and a bottom plate positioned at the backlight surface and connected with the hollow frame, wherein the transparent cover plate is one to two layers of polycarbonate membrane; the inner core of the hollow frame is hidden with a water transmission pipeline along the length direction; the water transmission pipeline is communicated with a heat absorbing pipe in the shelland a water inlet and a water outlet at the side surface of the hollow frame; the heat absorbing pipes are a row of parallel aluminium alloy pipes, the cross section thereof are shaped as an ellipseand the long shaft thereof is parallel to the transparent cover plate; the heat absorbing pipe is externally wrapped with an aluminium foil coated with a selective heat absorbing coating; and the twoends of the heat absorbing pipe are respectively communicated with the water transmission pipeline of the hollow frame. The aluminum-plastic solar heat collector solves the technical problems that thetraditional solar heat collector has high cost and undesirable heat efficiency, is hard to be fused with the building structure and the building shape and has influence to large-scale application.

Owner:周晓欣

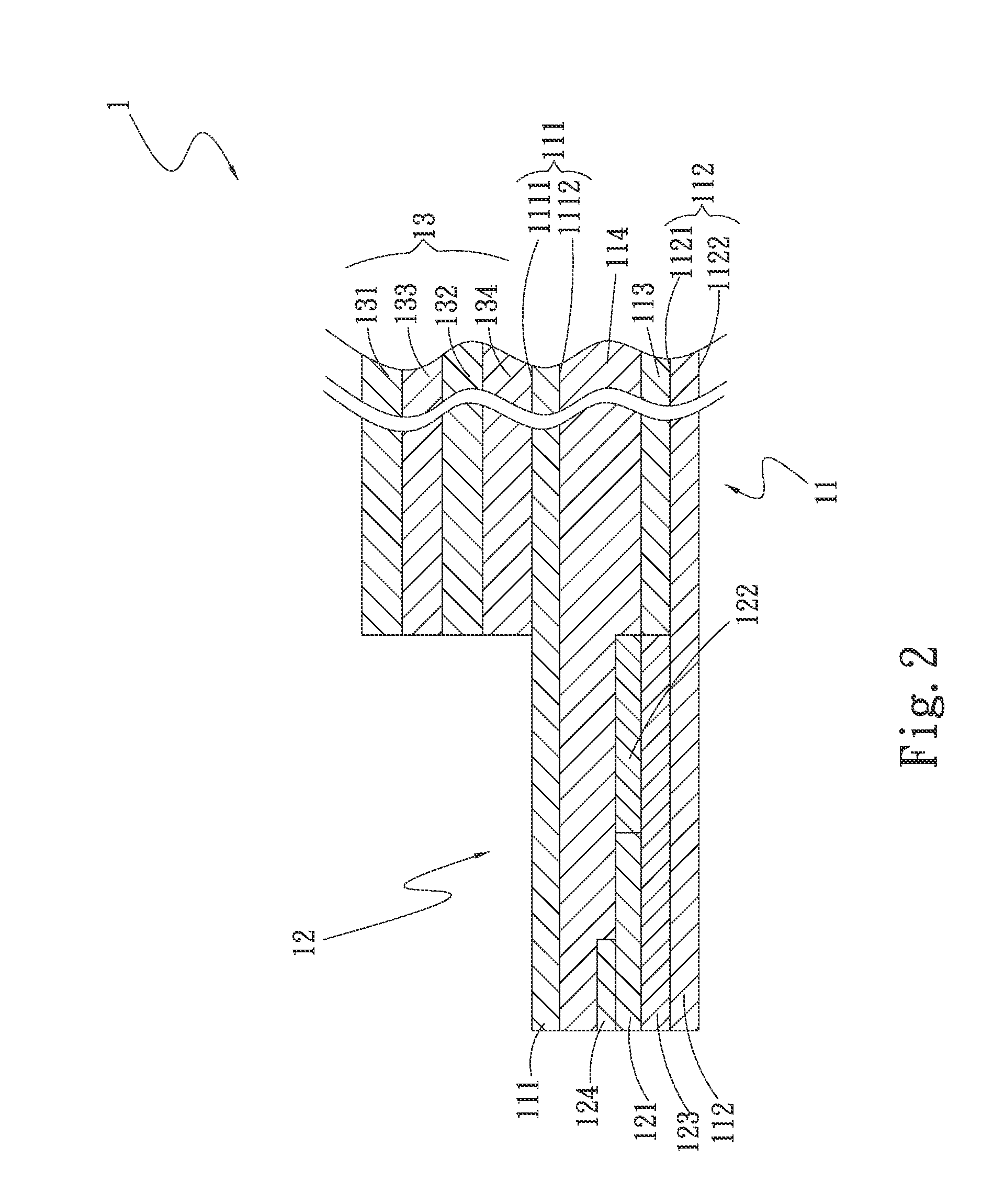

Touch panel with photovoltaic conversion function

InactiveCN103809789AExtend standby timeExtended use timeInput/output processes for data processingComputer scienceTouch panel

A touch panel with a photovoltaic conversion function comprises a touch control area and a non-touch control area adjacent to the touch control area, wherein the touch control area is internally provided with a first transparent substrate, a photovoltaic conversion layer, a touch control electrode layer and a second transparent substrate, the photovoltaic conversion layer is arranged on the first transparent substrate, and the touch control electrode layer is formed on one side of the second transparent substrate, and is adhered to the photovoltaic conversion layer. By the design of the touch panel provided by the invention, the light absorbing area of the photovoltaic conversion layer is effectively increased, so that the effect of increasing conversion current magnitude is realized.

Owner:林志忠

Photothermal conversion film, preparation method thereof and double-layer evaporation structure for solar steam generation

ActiveCN110726262AReduce heat transferTimely supplementSolar heating energyVacuum evaporation coatingPhysical chemistryPhotothermal conversion

The invention provides a high-performance foam metal-based photothermal conversion film, a preparation method thereof and a double-layer evaporation structure for solar steam generation. The high-performance foam metal-based photothermal conversion film is a CuO@CF or CuO / Ag@CF photothermal conversion film, the CuO@CF or CuO / Ag@CF photothermal conversion film and melamine foam form the double-layer evaporation structure for solar steam generation, then downward conduction heat loss from a solar absorber to underlying water occurring in a single layer evaporation system is reduced, and evaporation efficiency is further improved; and compared with a traditional pure noble metal material film, the CuO / Ag@CF photothermal conversion film has lower cost.

Owner:SHAANXI UNIV OF SCI & TECH

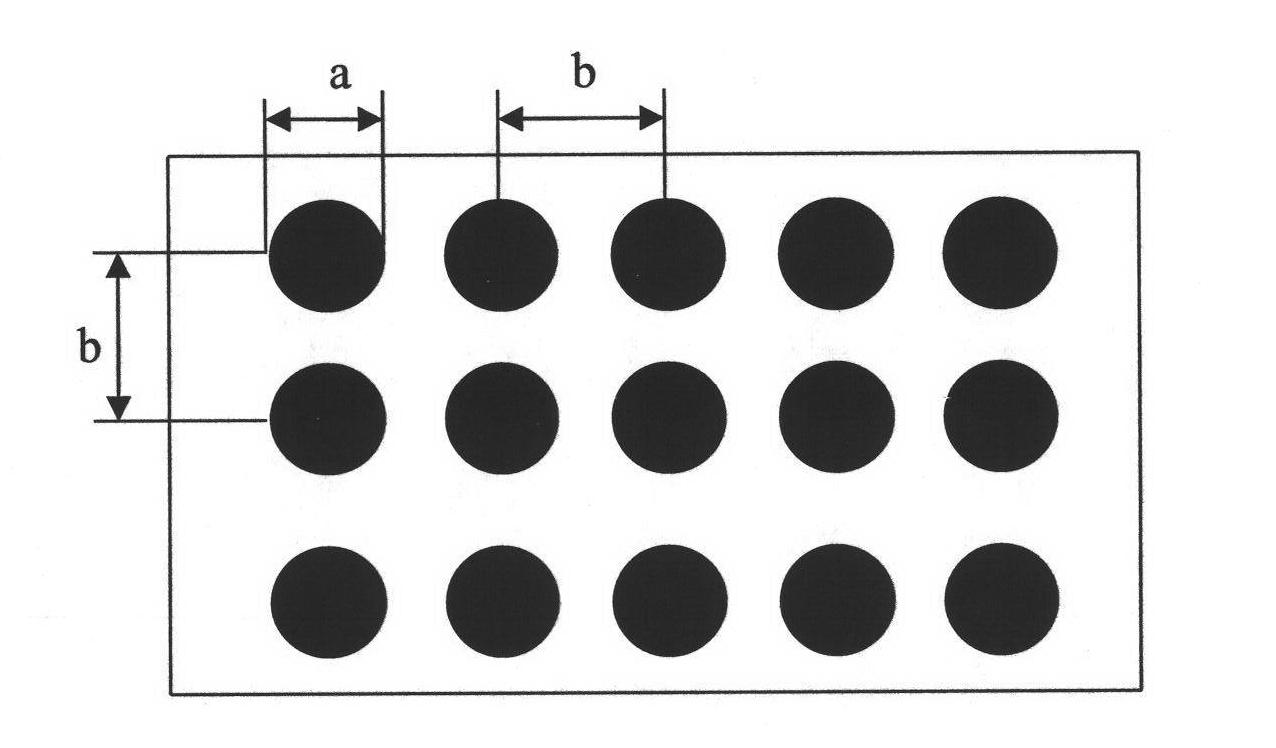

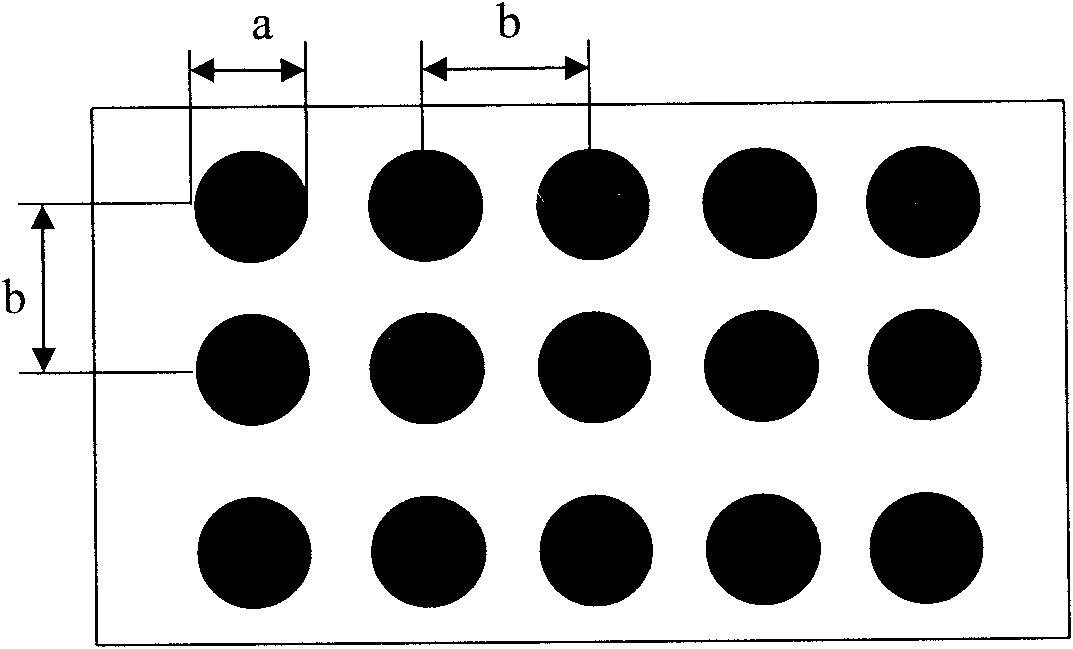

Method for surface regulation of silicon material for solar cells

InactiveCN101866982AIncrease light absorption areaEnsure uniformity and regularityFinal product manufactureSemiconductor devicesCorrosionSolar cell

The invention discloses a method for the surface regulation of a silicon material for solar cells. In the method, photoetching and mask film technology and alkaline wet-method corrosion technology are combined, a layer of mask film is deposited on the surface of silicon before the alkaline wet-method corrosion of the surface of the silicon, and the film layer on the surface of the silicon is patterned by a mask film pattern to make the corrosion of the surface of the silicon selectable and controllable. While performing the alkaline wet-method corrosion of the surface of the silicon to increase the light absorption area of the surface of the silicon, the method ensures the uniformity and regularity of the surface of the silicon. The method has the advantages of controllable operation, simplicity, easy implementation, high repeatability and easy large-scale production application.

Owner:UNIV OF ELECTRONIC SCI & TECH OF CHINA

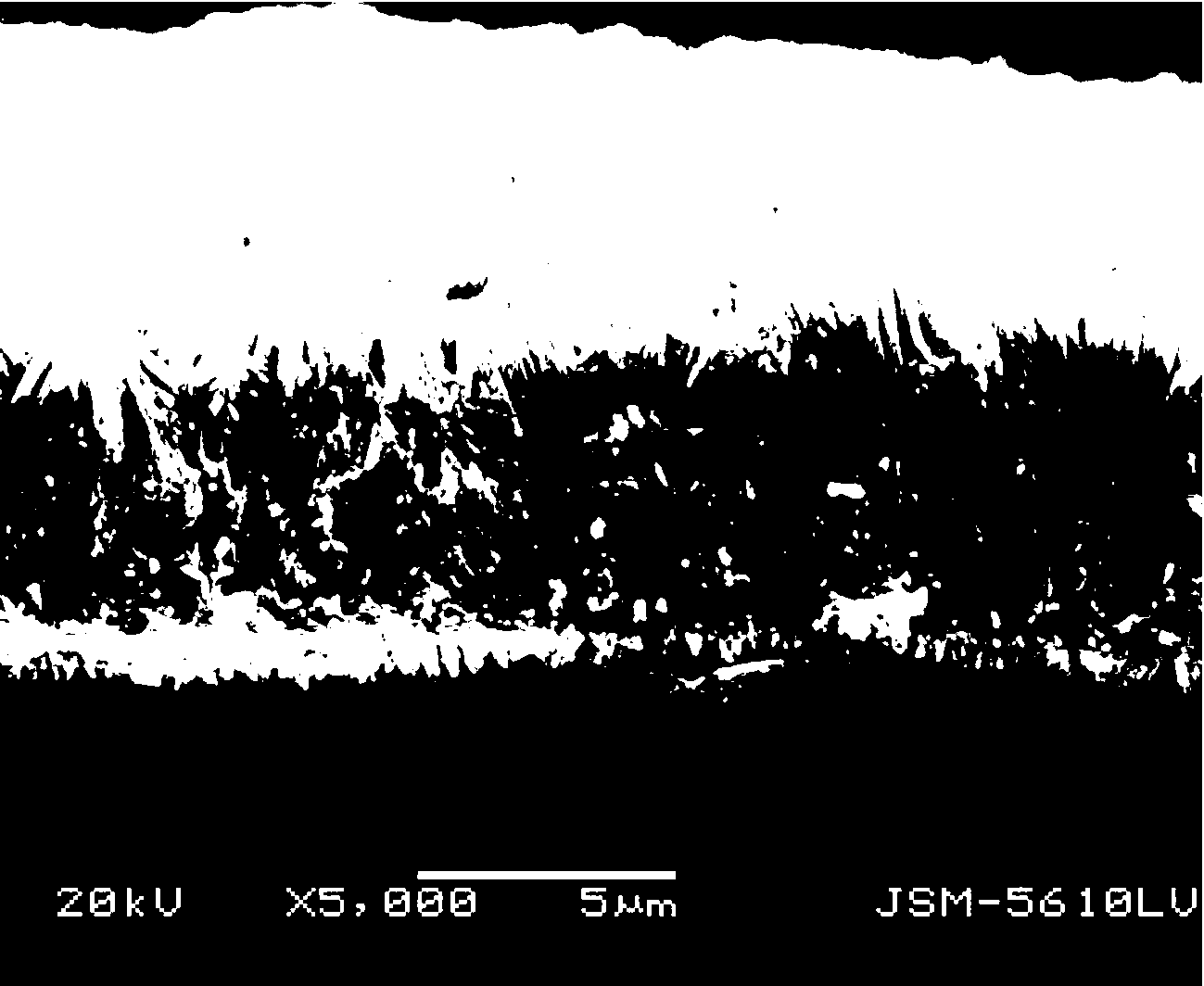

Preparation method of thorn-ball photochromic MoO3 thin film

InactiveCN103288138AReduce polarityChange original orientationMolybdenum oxides/hydroxidesMolybdic acidMaterials science

The invention discloses a preparation method of a thorn-ball photochromic MoO3 thin film. The preparation method comprises the following steps: (1) preparing a 0.05-3mol / L molybdate liquor; (2) adding a formaldehyde liquor to the molybdate liquor, adjusting the pH of the liquor by a pH adjustor to 0.8-1.5, and stirring and homogenizing in dark light; (3) transferring the homogenized reaction liquor to a reaction container, and placing a clean transparent conductive oxide crystal substrate for hydrothermal reaction; (4) after hydrothermal reaction, cooling to reaction system to room temperature, taking out the crystal substrate plated with film from the container for hydrothermal reaction, and washing with water and alcohol and drying to prepare the thorn-ball photochromic MoO3 thin film. The MoO3 thin film prepared by the invention can generate a good photochromic effect under a condition of a low power excitation light source, and the photochromic performance of the MoO3 thin film is improved.

Owner:CHINA UNIV OF GEOSCIENCES (WUHAN)

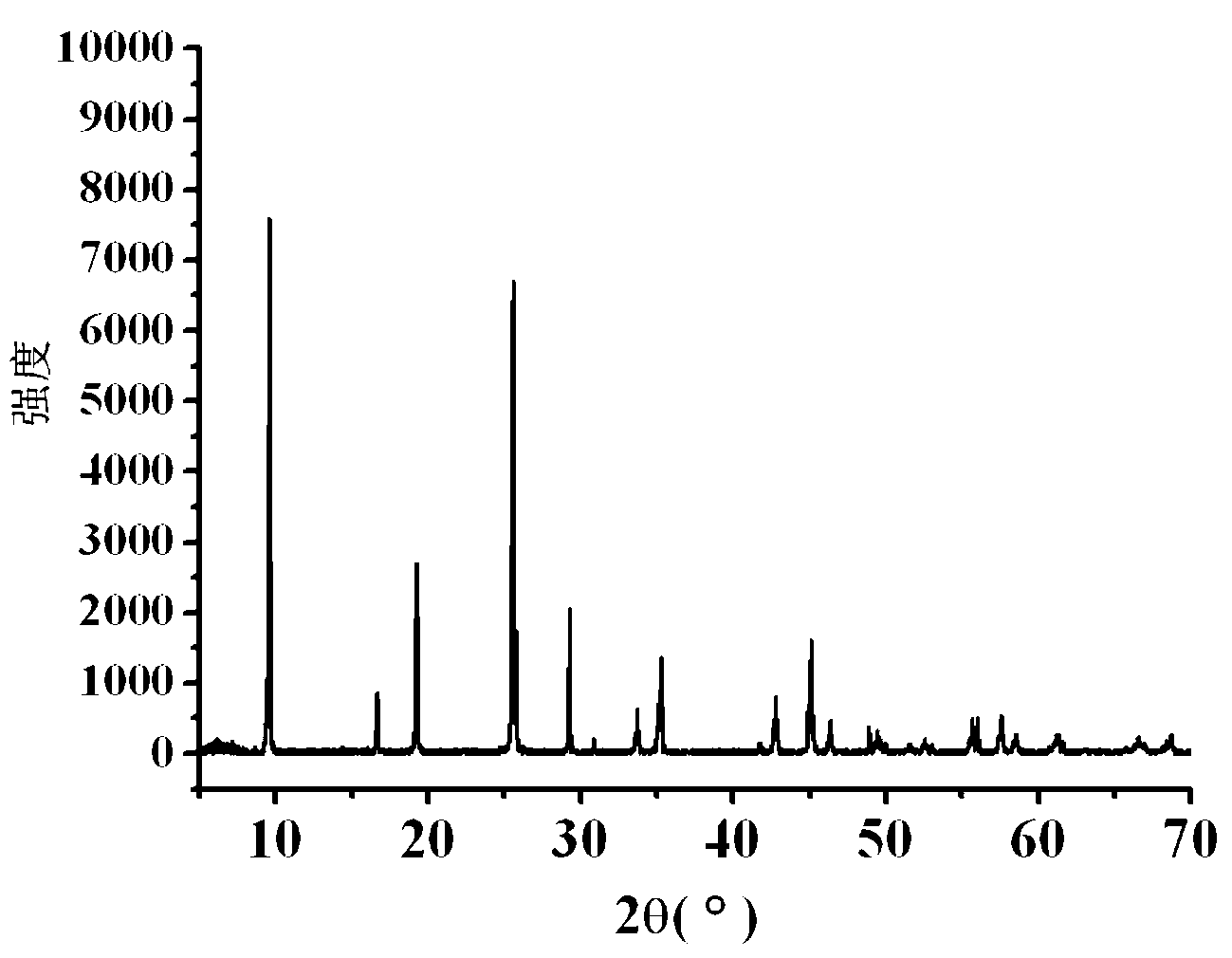

Heterogeneous junction solar cell edge insulating method

InactiveCN106816493AConducive to large-scale automated productionIncrease light absorption areaFinal product manufacturePhotovoltaic energy generationSputteringAmorphous silicon

The present invention discloses a heterogeneous junction solar cell edge insulating method. The method includes the following steps that: texturization is performed on two surfaces of an N type silicon wafer, so that pyramid texturized surfaces can be formed; a first intrinsic layer and an N type amorphous silicon thin film layer are deposited on one surface of the texturized N type silicon wafer, a second intrinsic layer and a P type amorphous silicon thin film layer are deposited on the other surface; conductive film layers are formed on the N type amorphous silicon thin film layer and the P type amorphous silicon thin film layer through sputtering; metal grid line electrodes are formed on the conductive film layers; etching paste is printed on the periphery of the shady surface (P surface) or light receiving surface (N surface) of the N type silicon wafer; and the N type silicon wafer printed with the etching paste is baked, and the conductive film layers and the etching paste at the periphery of the wafer can be removed. According to the heterogeneous junction solar cell edge insulating method of the invention adopted, the etching paste is printed at the periphery of the wafer, so that a frame pressing mode conducted in the sputtering process of the conductive thin films can be omitted, and therefore, frame pressing is not required in the deposition process of the conductive thin films, the conductive film layers can be formed on the whole two surfaces of the silicon wafer through sputtering, and the large-scale automated production of the conductive film layers can be benefitted.

Owner:GS SOLAR CHINA COMPANY

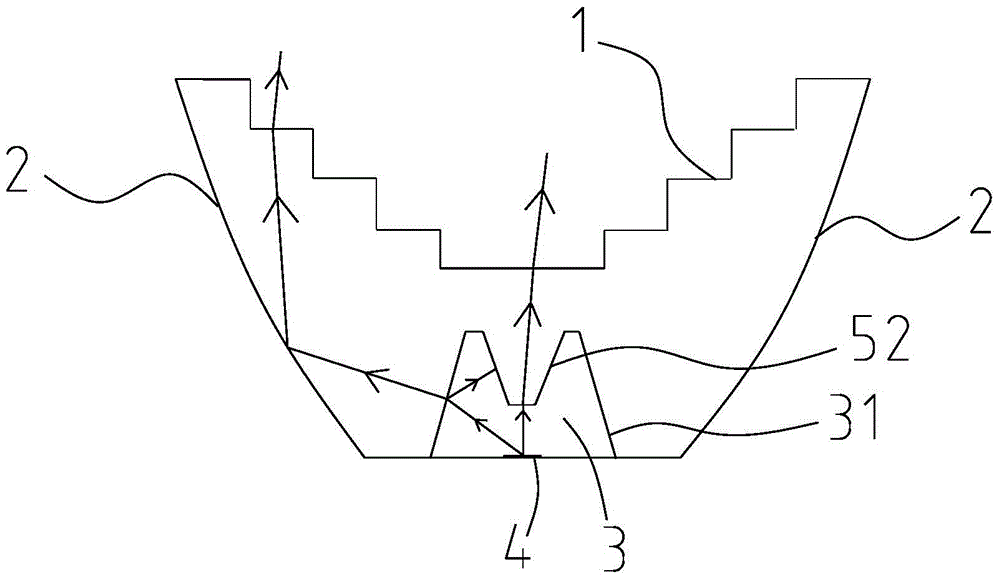

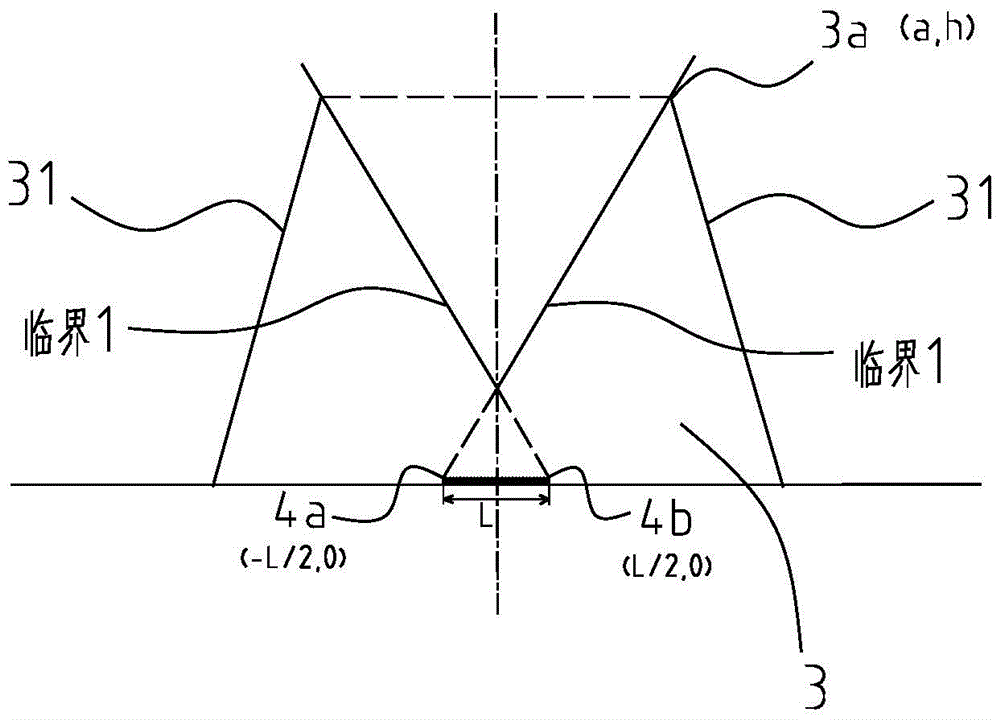

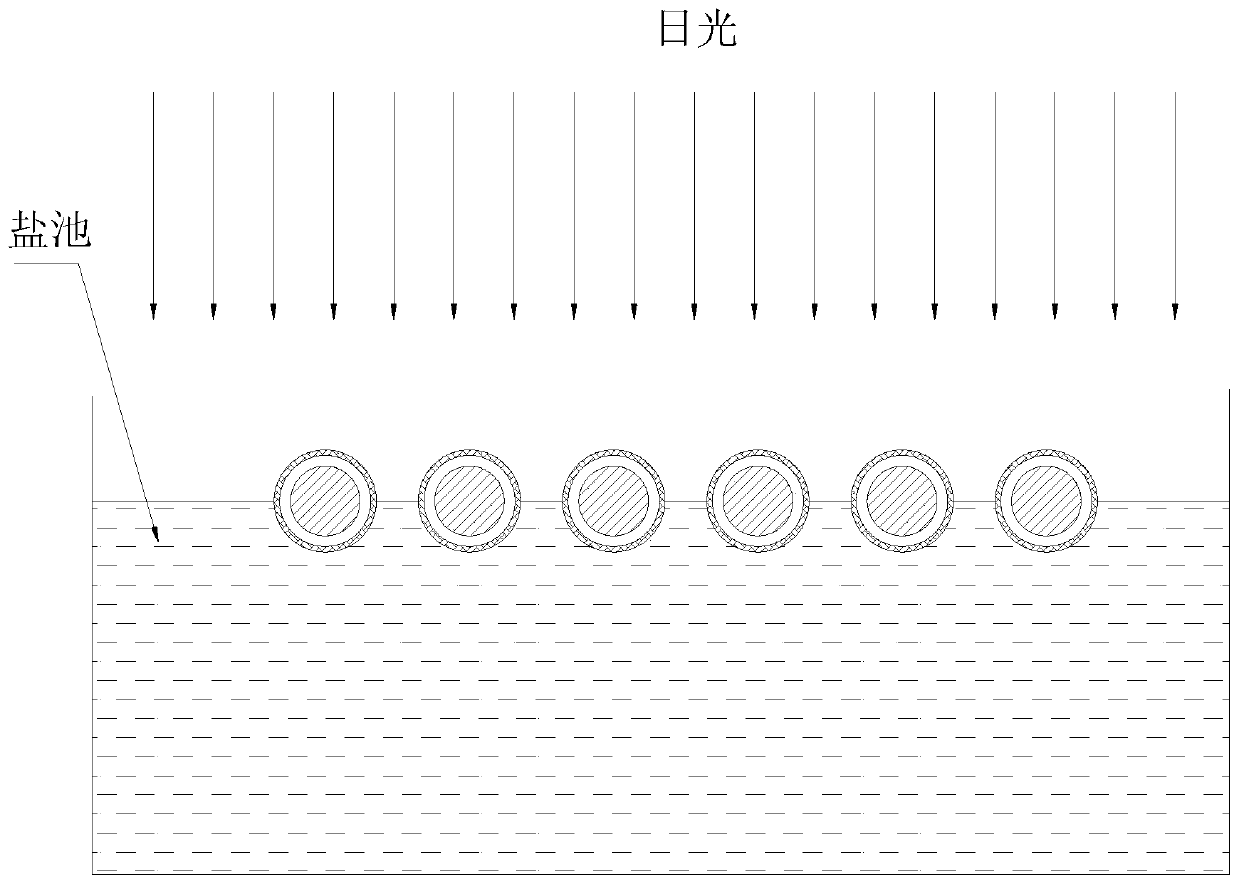

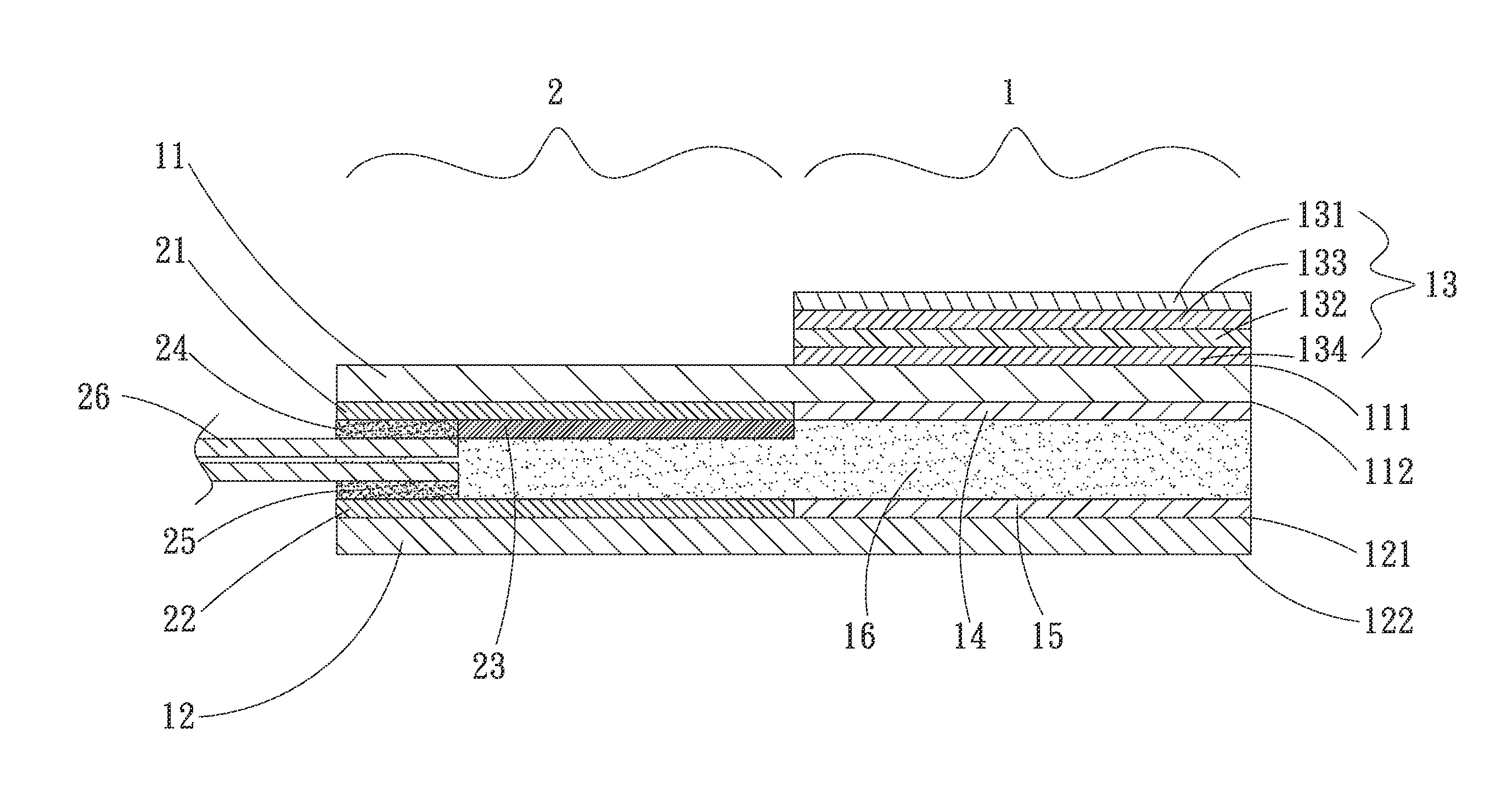

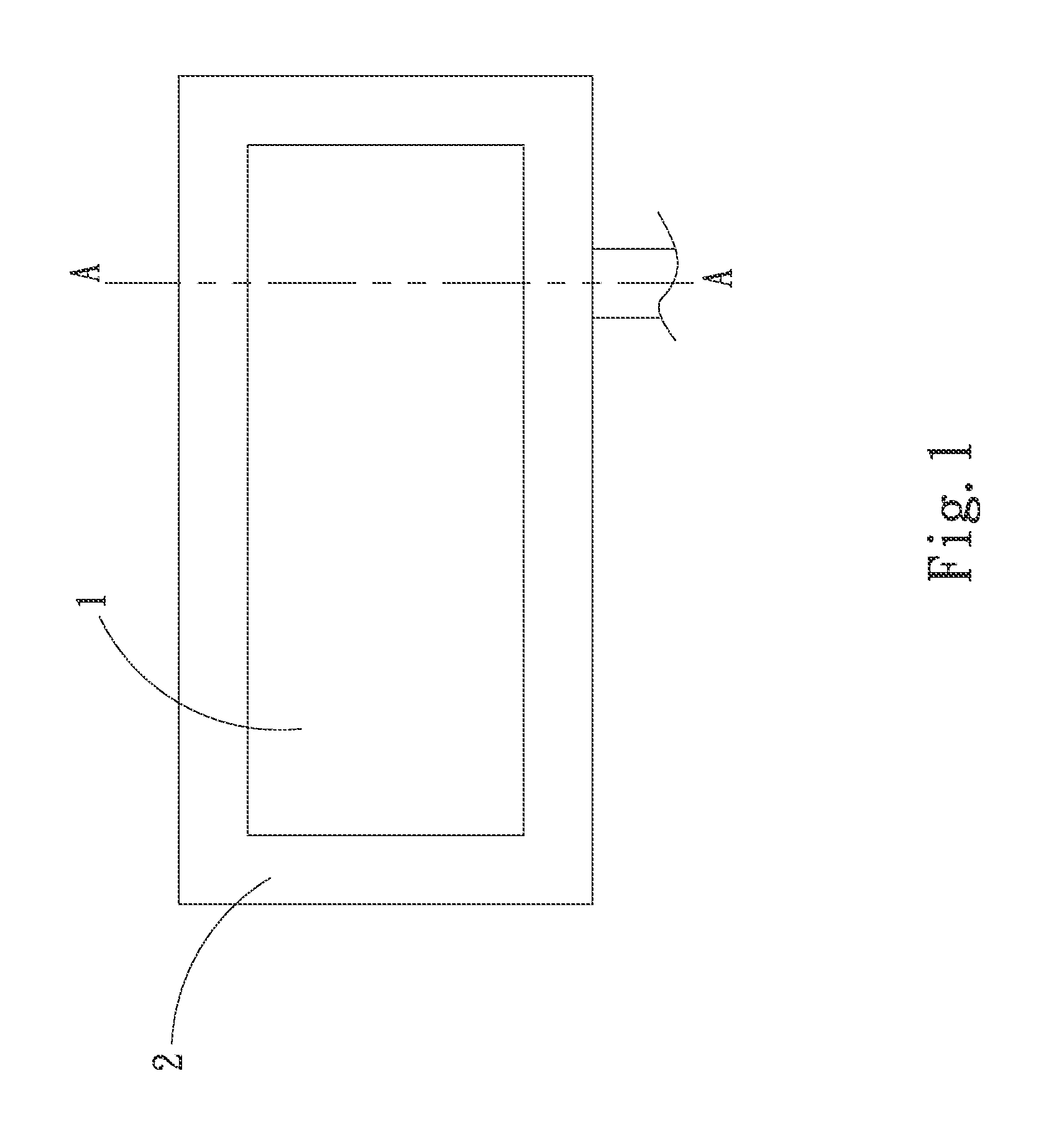

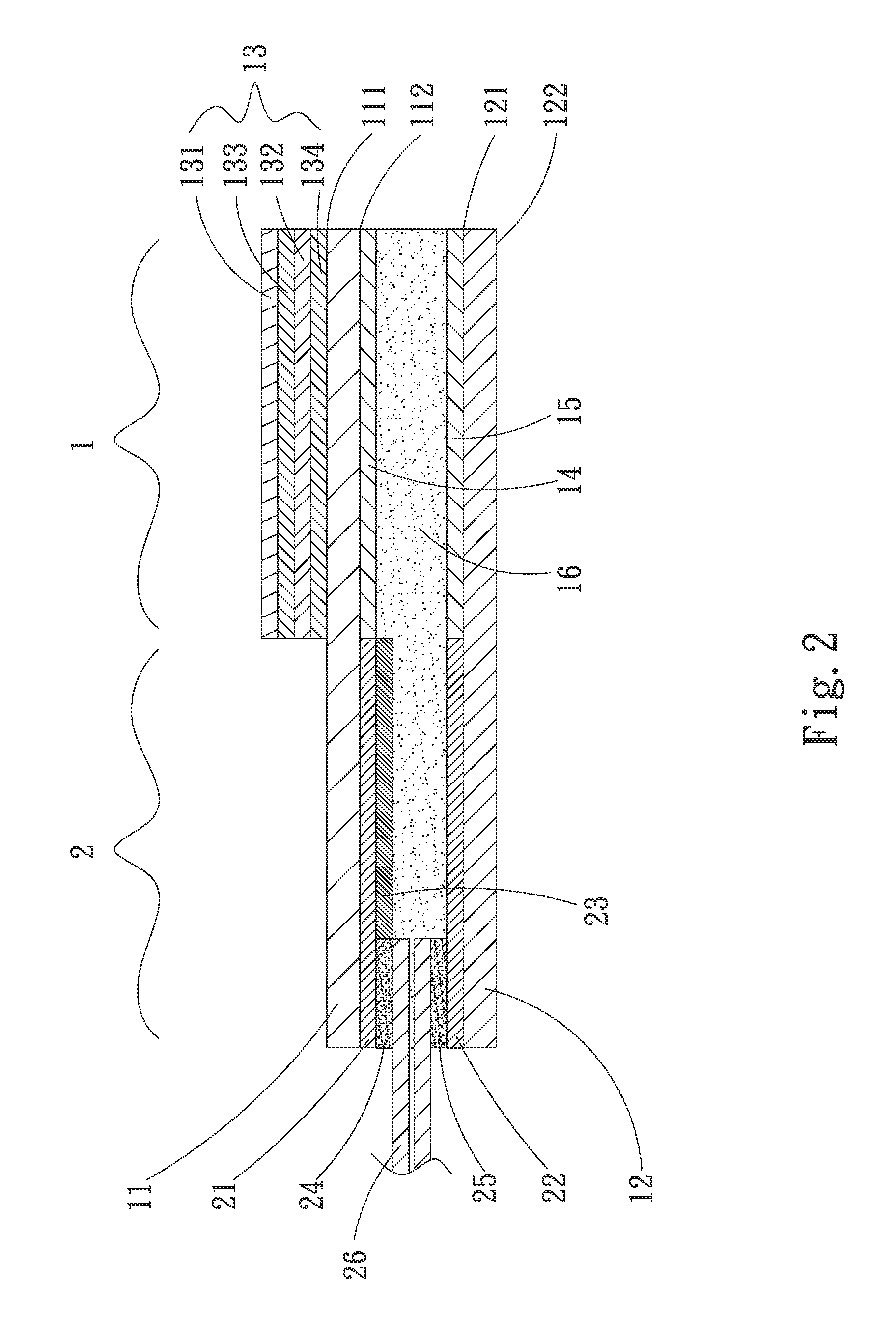

Method and device for accelerating salt obtaining by evaporating brine

PendingCN110040801AHydrophilicPorousWater/sewage treatment by heatingAlkali metal chloridesSalt-wastingEvaporation

The invention provides a device for accelerating salt obtaining by evaporating brine. The device comprises a light-heat conversion part, a buoyancy ball and a locking part, wherein the light-heat conversion part wraps the buoyancy ball, and the locking part fastens the light-heat conversion part. The invention further provides a method for accelerating salt obtaining by evaporating brine. The method comprises the following steps that an aqueous solution to be treated is added, accessories are selected and assembled, the light-heat conversion part wraps the buoyancy ball and is fastened by using the locking part, the device is placed in a water pool, the buoyancy ball floats in the water pool, the remaining part of the light-heat conversion part stretches into the water pool to carry out light absorption and light-heat conversion so as to quickly evaporate water absorbed by the light-heat conversion part, the light-heat conversion part carries out capillary action to quickly supply water. The device and method disclosed by the invention have the beneficial effects that the use effect is excellent, the water evaporation efficiency can be improved, the production period of salt obtaining by evaporating brine in the open air can be shortened, and the treatment time of multiple sewage such as high-salt waste water, heavy-metal sewage and printing and dyeing sewage can be shortened,so that large economic benefit and social benefit can be brought.

Owner:江苏金羿射日新材料科技有限公司

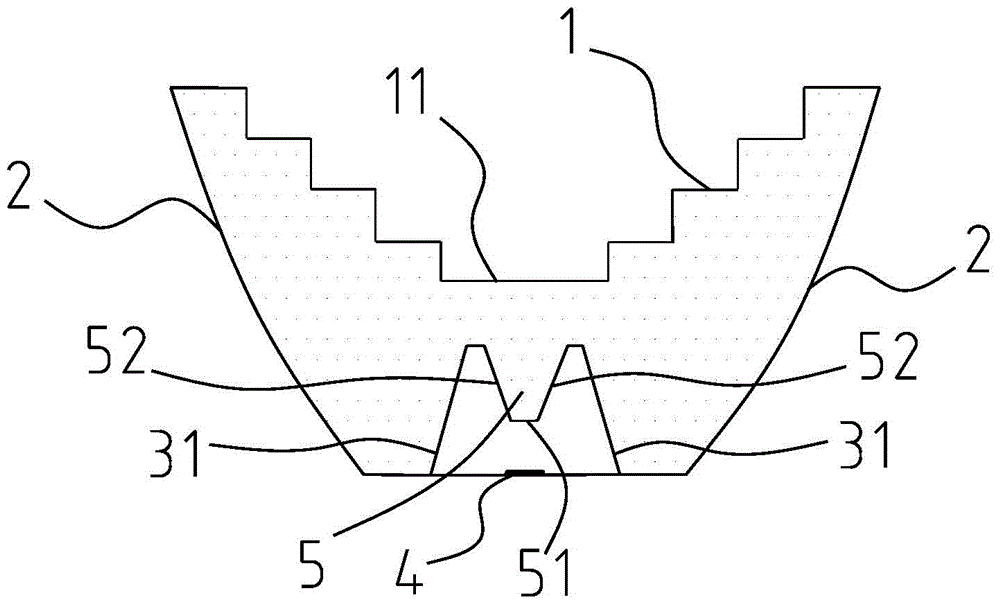

ABO3 perovskite-based thin film solar cell

InactiveCN107681055AIncrease the amount of light absorbedImprove efficiencySolid-state devicesSemiconductor/solid-state device manufacturingElectron transmissionElectricity

The invention provides a perovskite-based thin film solar cell. The solar cell comprises a transparent electrode layer, an electron transmission layer, a perovskite light absorption layer, a hole transmission layer and a metal electrode layer, wherein the perovskite light absorption layer is provided with a first surface and a second surface, the first surface and the second surface are provided with a plurality of convex-concave parts, and a cross section of each convex-concave part is an isosceles triangle with a top angle being 150 degrees. In the perovskite-based thin film solar cell, contact surfaces among the perovskite light absorption layer, the electron transmission layer and the hole transmission layer are of convex-concave structures, and thus, the light absorption area of the perovskite light absorption layer is expanded; since a surface of the light absorption layer is an isosceles triangle with an angle being an obtuse angle, more light rays can be reflected, so that sunlight absorption quantity is further improved, and the efficiency of power generation from light is effectively improved; and meanwhile, the transmission area of electrons and holes which are generatedby the light absorption layer is expanded, the transmission efficiency of the electrons and the holes which are generated by the light absorption layer is improved, so that the stability of a currentand a battery is improved.

Owner:成都赛伦斯环保科技有限公司

Flexible gallium arsenide solar cell and manufacturing method thereof

InactiveCN111799344AFacilitated releaseEasy to manufactureFinal product manufacturePhotovoltaic energy generationMetallic electrodeThin membrane

The invention relates to a flexible gallium arsenide solar cell and a manufacturing method thereof. The flexible gallium arsenide solar cell comprises a graphical PI substrate, a gallium arsenide epitaxial layer, an upper electrode and an antireflection film, wherein a lower electrode is evaporated at the bottom of the graphical PI substrate, bonding metal is evaporated above the graphical PI substrate and below the gallium arsenide epitaxial layer, and the PI thin film and the epitaxial layer are bonded through the bonding metal. The gallium arsenide epitaxial layer can be an inverted single-junction gallium arsenide solar cell or a multi-junction gallium arsenide solar cell. The metal electrode is arranged on the back surface of the flexible cell and can be directly attached to the surface of equipment for use, the subsequent packaging process is simplified, and the heat dissipation performance of the flexible gallium arsenide solar cell can be improved and the stability of a productis improved due to direct attachment to the surface of the equipment; by using the rigid transparent rigid temporary substrate, the conditions of high cost and high pollution caused by using galliumarsenide as the temporary substrate are reduced, and the risk of damaging the epitaxial layer when the temporary substrate is removed is reduced.

Owner:NANCHANG KAIXUN PHOTOELECTRIC CO LTD

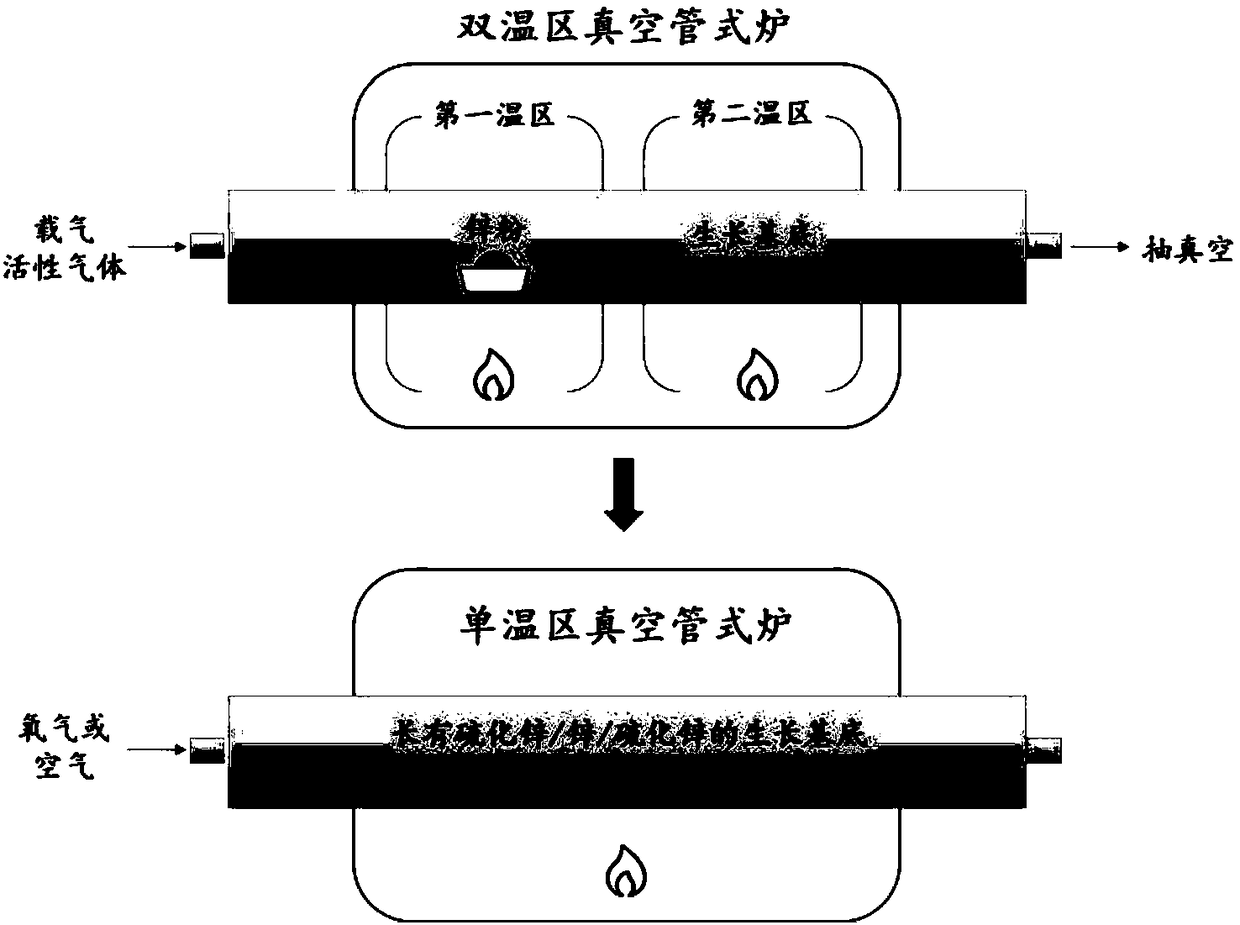

Two-dimensional ZnS/ZnO/ZnS nanosheet photocatalyst and preparation method thereof

InactiveCN108404933AEasy transferIncrease light absorption areaPhysical/chemical process catalystsGas phaseEvaporation

The invention belongs to the technical field of photocatalysts, and discloses a two-dimensional ZnS / ZnO / ZnS nanosheet photocatalyst and a preparation method thereof. The nanosheet is a sandwich structure formed by sequential arrangement of a ZnS layer, a ZnO layer and a ZnS layer, the nanosheet has a thickness of 5-10 nm and a lateral dimension of 1-10 [mu]m; the outermost ZnS layer has a thickness of 1-2 atomic layers; as a photocatalyst, the nanosheet has a band gap of 2.6-2.8 eV; and the preparation method comprises the steps of performing thermal evaporation on zinc powder in a gas phase,utilizing a carbon disulfide or sulfur dioxide active gas to obtain a nanosheet template, and performing oxidizing annealing to obtain the ZnS / ZnO / ZnS nanosheet. Compared with other ZnO nano materials, the two-dimensional ZnS / ZnO / ZnS nanosheet provided by the invention has the sandwich structure, and has a smaller band gap and a thinner thickness as a photocatalyst; and in addition, the preparation method provided by the invention has a simple process, smart design and low costs, and is safe and controllable.

Owner:TIANJIN UNIV

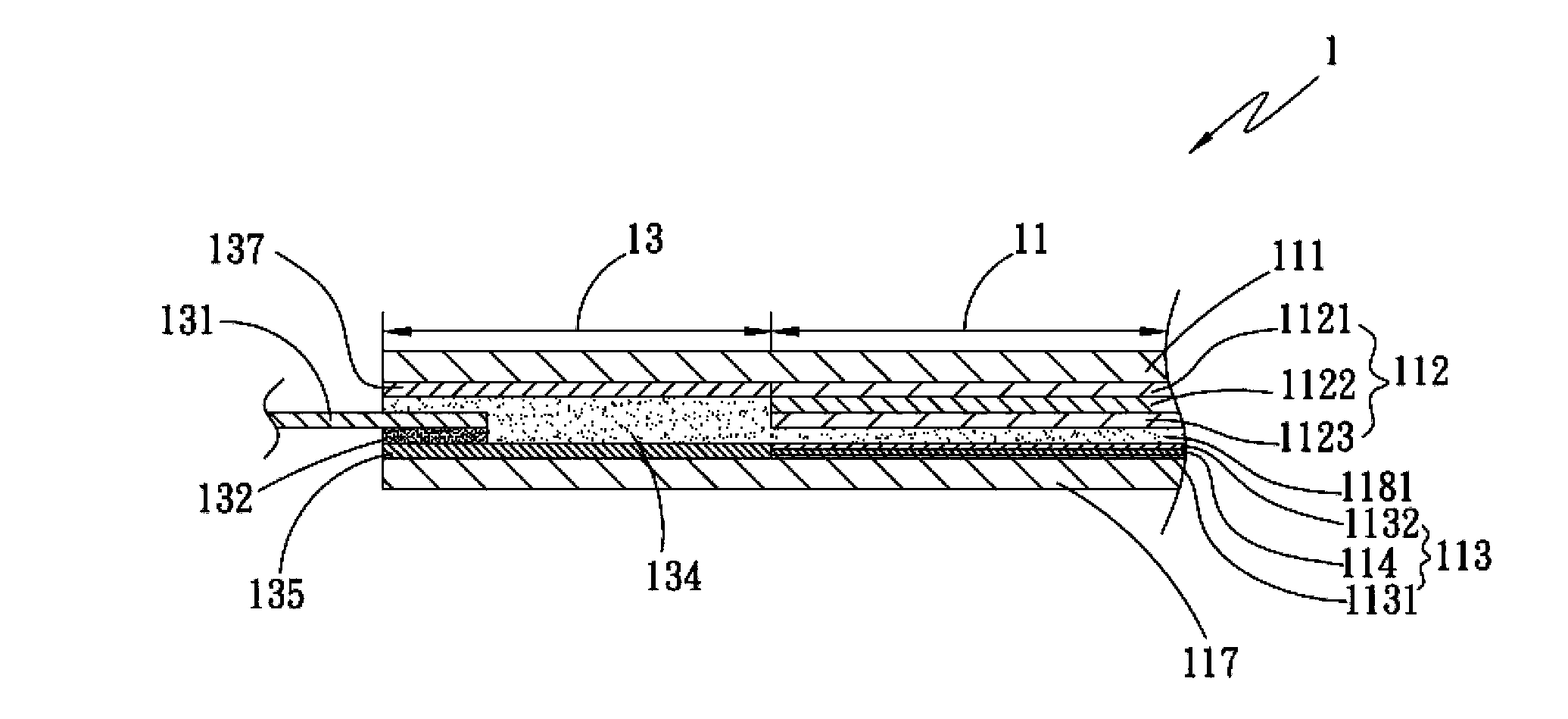

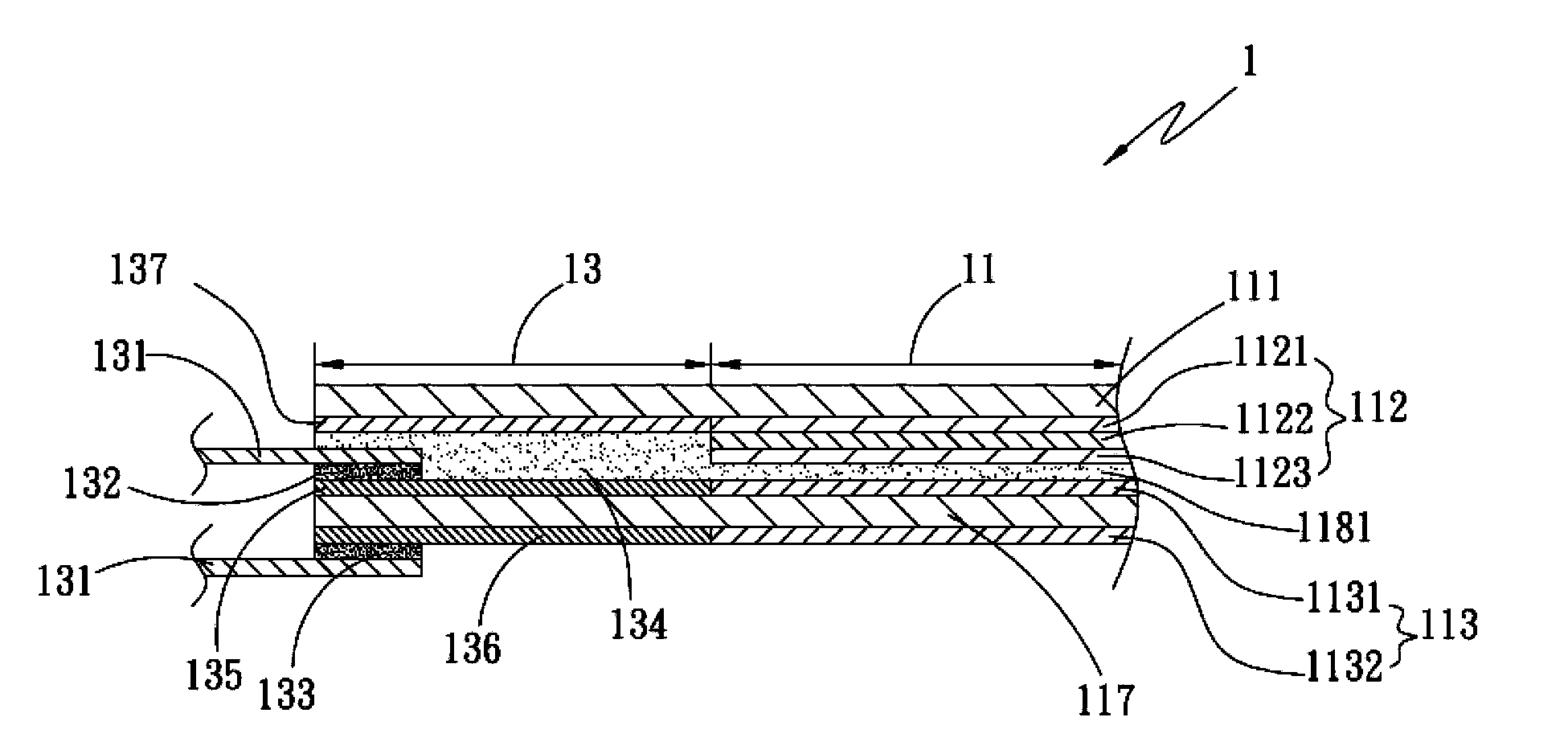

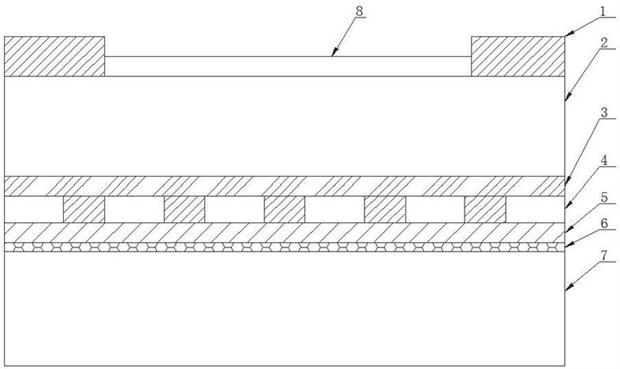

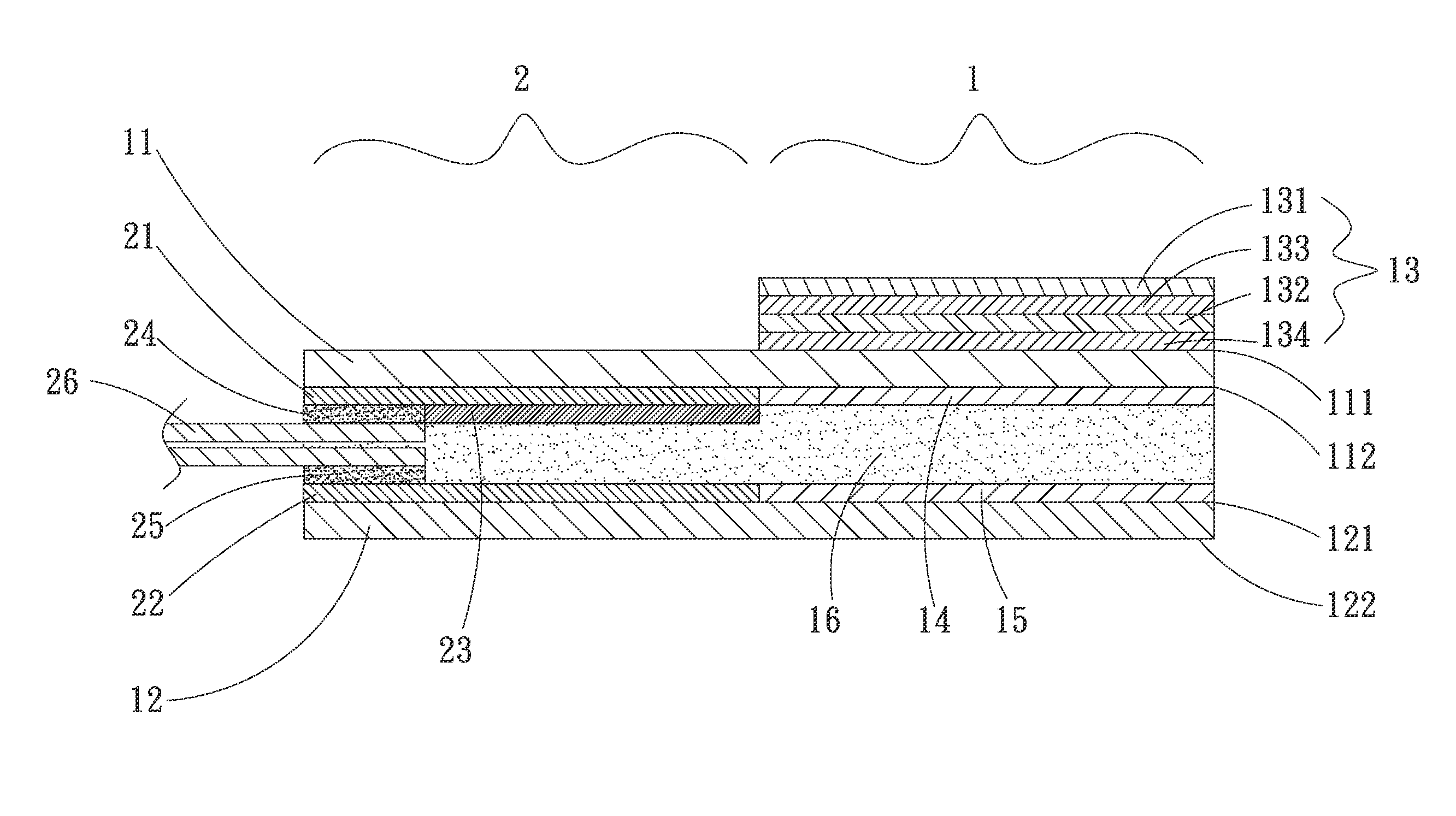

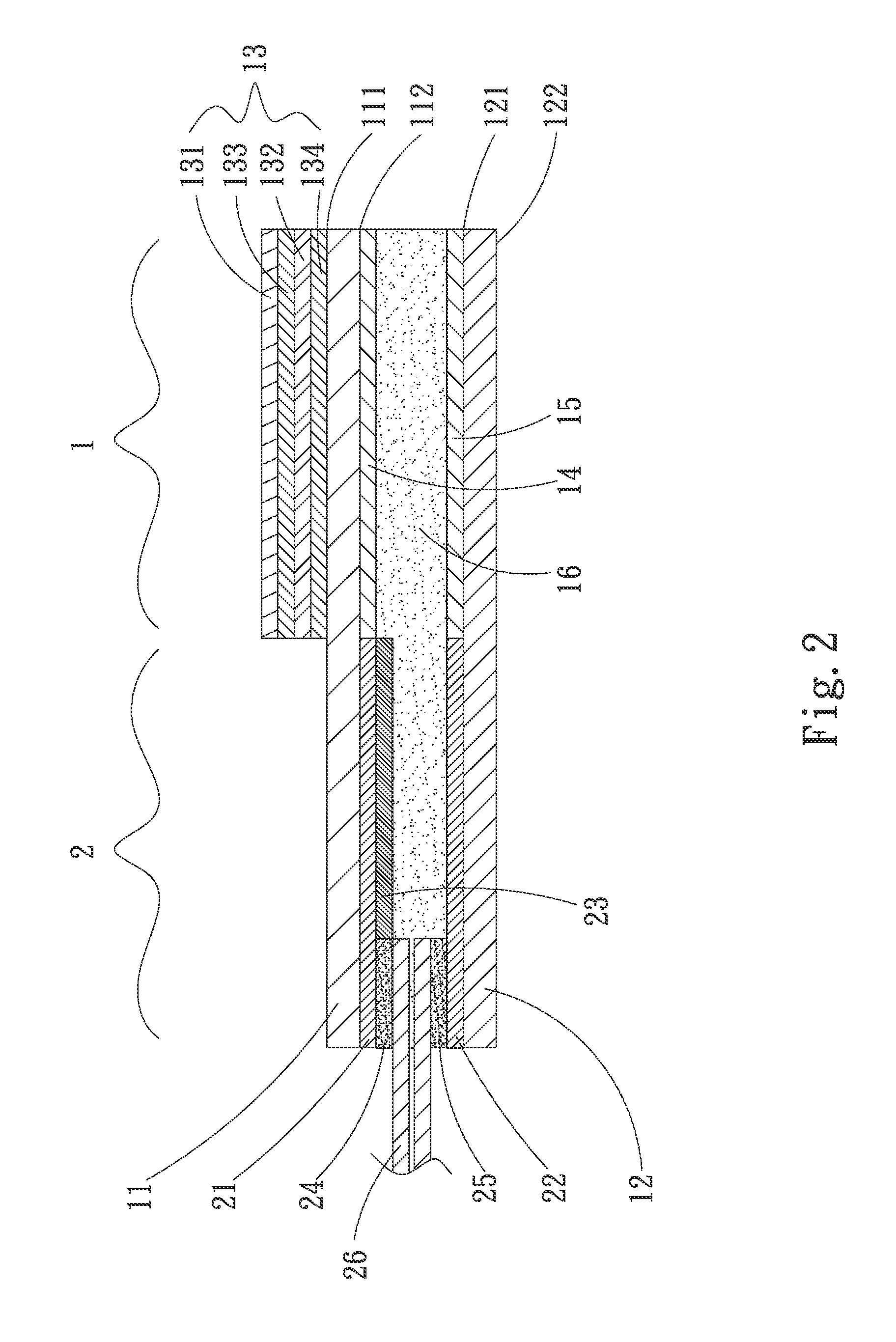

Touch module with photovoltaic conversion function

InactiveUS8853554B2Extension of timeIncrease the areaInput/output for user-computer interactionCurrent/voltage measurementComputer moduleEngineering

A touch module with photovoltaic conversion function includes a touch zone and a non-touch zone. The touch zone includes a first clear substrate, a second clear substrate and a photovoltaic conversion unit. The first clear substrate has opposite first and second sides, and the second clear substrate has opposite third and fourth sides. A first and a second touch electrode layer are provided on the second side and the third side, respectively; and the photovoltaic conversion unit is provided on the first side of the first clear substrate. By providing the photovoltaic conversion unit in the touch zone of the touch module, the photovoltaic conversion unit can have increased light-absorption areas to enable conversion of light into more electric current and accordingly, enable a touch device using the touch module to have extended standby and operation time.

Owner:LIN CHIH CHUNG

a condenser lens

InactiveCN104132305BImprove uniformityHeterocyclic Halo AvoidanceSemiconductor devices for light sourcesRefractorsOptoelectronicsUltimate tensile strength

The invention discloses a condensing lens which comprises a light outlet face, a lateral curved face and a light inlet face. The light inlet face is arranged at the bottom of the condensing lens and is concavely arranged in the condensing lens to form an inner cavity for accommodating a light source. A step protruding to one side of the light source is arranged at the top of the inner cavity, the lateral wall of the inner cavity serves as a first light inlet face, and all points on the step are arranged above a straight line formed by the connection between one end of the top of the inner cavity and the relative end of the light source. Light reflected by a first light emitting face can be projected to the surface of the step and can be scattered or absorbed by the surface of the step. The step can prevent the reflected light from entering the condensing lens from the other side of the inner cavity, so that no miscellaneous aureole and no miscellaneous halo are generated around light spots projected by the condensing lens, and the evenness and the visual attractiveness of the light spots are greatly improved. Meanwhile, light generated by the condensing lens can be gathered at the central light strength position, the central light strength and the brightness of the light spots are improved, and the light outlet efficiency is high. The condensing lens is simple in structure, strong in workability and easy to produce.

Owner:FOSHAN INST SUN YAT SEN UNIV +1

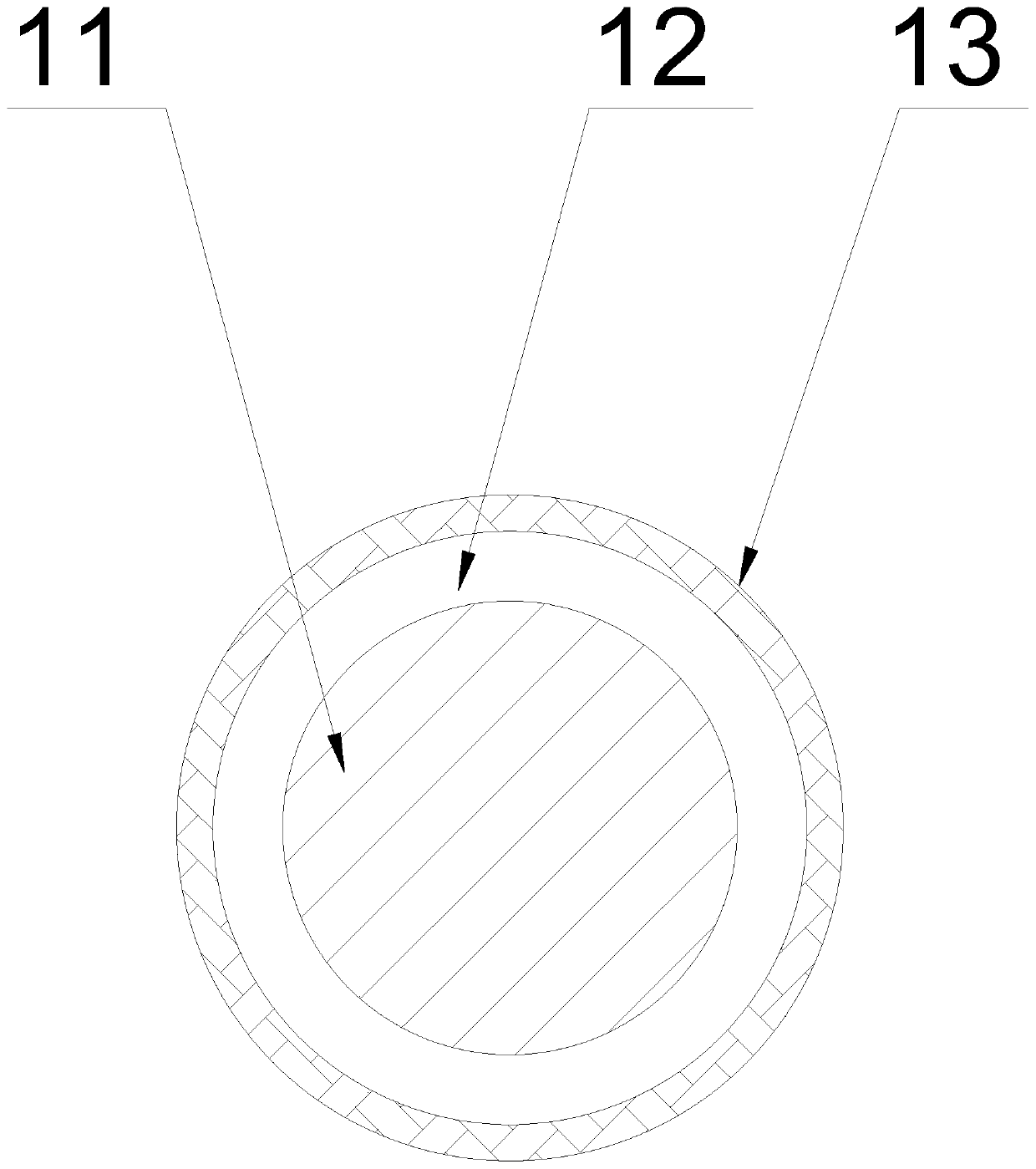

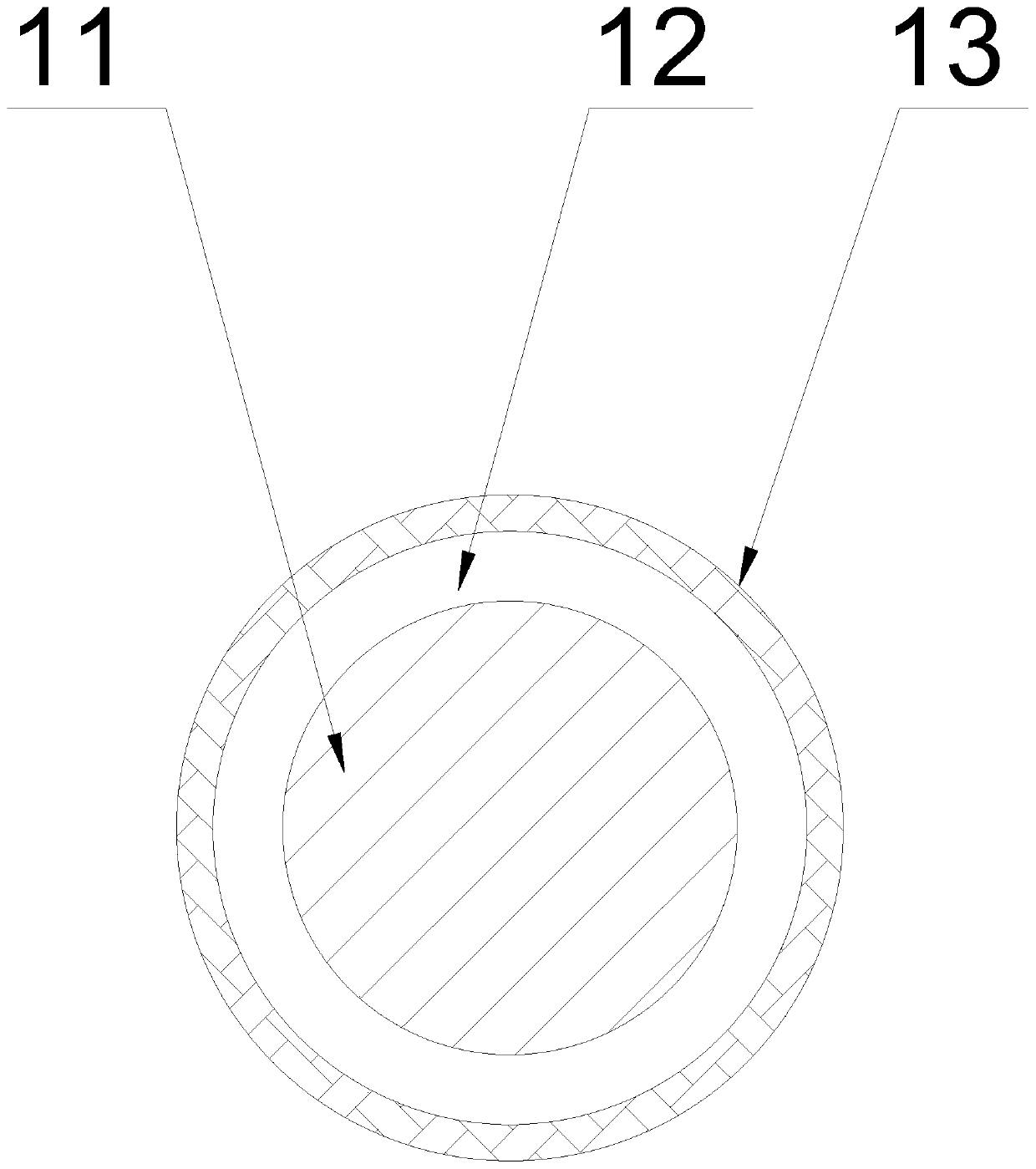

Method for accelerating sun-dried salt making by hydrophilic material and device

InactiveCN110001146ASpeed up evaporationBand widthSynthetic resin layered productsEnergy inputLight energyEvaporation

The invention relates to a method for accelerating sun-dried salt making by a hydrophilic material and a device. The device comprises a buoyancy layer, a water supply layer and a light absorption layer, wherein the buoyancy layer is cylindrical, the water supply layer wraps the periphery of the buoyancy layer, the light absorption layer wraps the periphery of the water supply layer, and thus, a device body can be cylindrical; and both the water supply layer and the light absorption layer have hydrophilicity. According to the method and the device, the device achieves rapid sun-dried salt making through accelerating moisture evaporation by using a hydrophilic optothermal material. The device is cylindrical, and one face, located above a water surface, of the device is arc-shaped, so that the surface of the device can be thoroughly irradiated by sunlight from various angles, and the light absorption area is increased. Heat is generated and is conducted to the surface of the water supplylayer after the light absorption layer absorbs light energy, so that a layer of water film between the light absorption layer and the water supply layer is heated, and the flash evaporation of moisture is achieved.

Owner:江苏金羿射日新材料科技有限公司

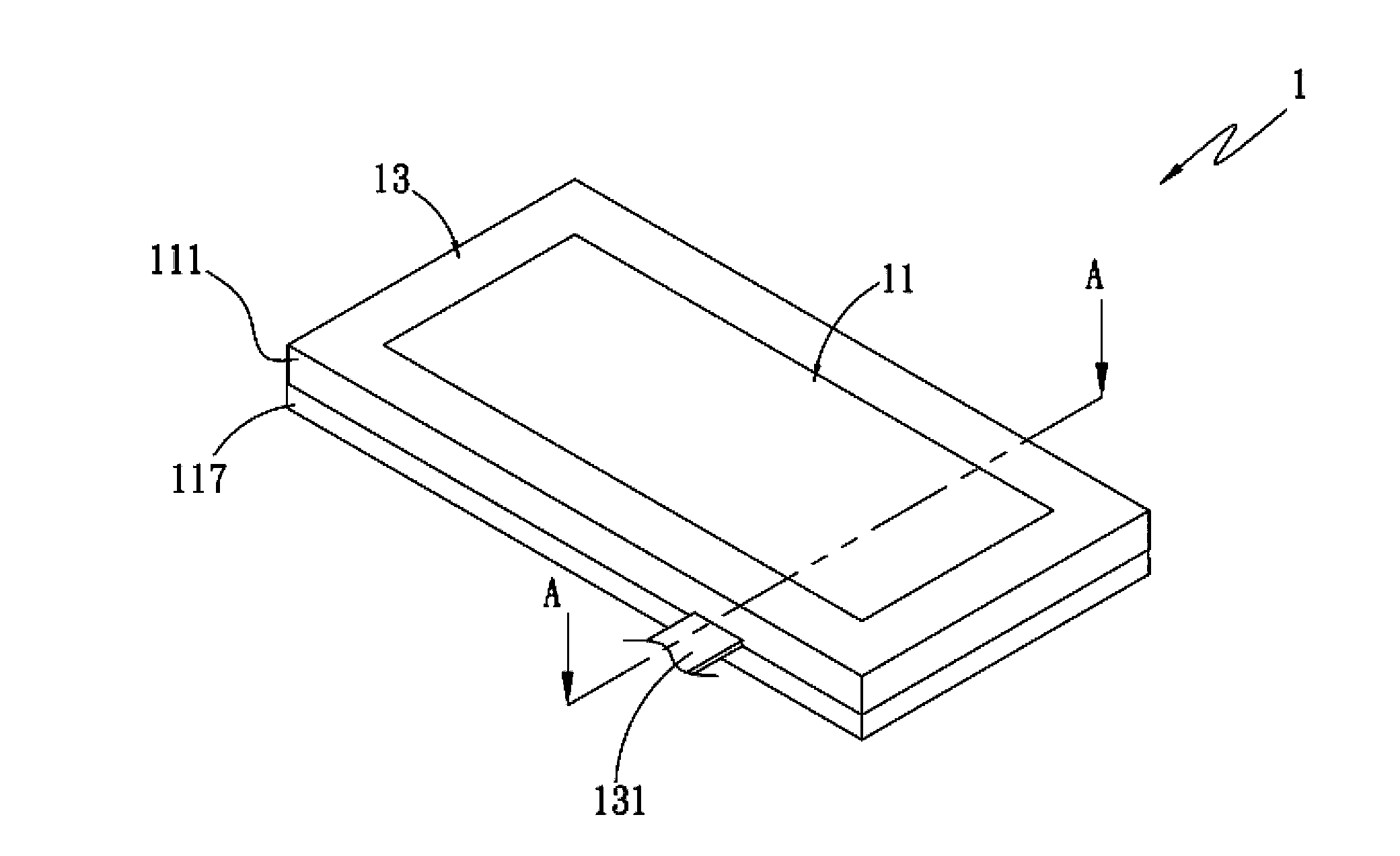

Touch module with photovolatic conversion function

InactiveUS20140126122A1Increase light absorption areaExtended operating timeCurrent supply arrangementsCircuit arrangements with support structuresEngineeringOperation time

A touch module with photovoltaic conversion function includes a touch zone and a non-touch zone. The touch zone includes a first clear substrate, a second clear substrate and a photovoltaic conversion unit. The first clear substrate has opposite first and second sides, and the second clear substrate has opposite third and fourth sides. A first and a second touch electrode layer are provided on the second side and the third side, respectively; and the photovoltaic conversion unit is provided on the first side of the first clear substrate. By providing the photovoltaic conversion unit in the touch zone of the touch module, the photovoltaic conversion unit can have increased light-absorption areas to enable conversion of light into more electric current and accordingly, enable a touch device using the touch module to have extended standby and operation time.

Owner:LIN CHIH CHUNG

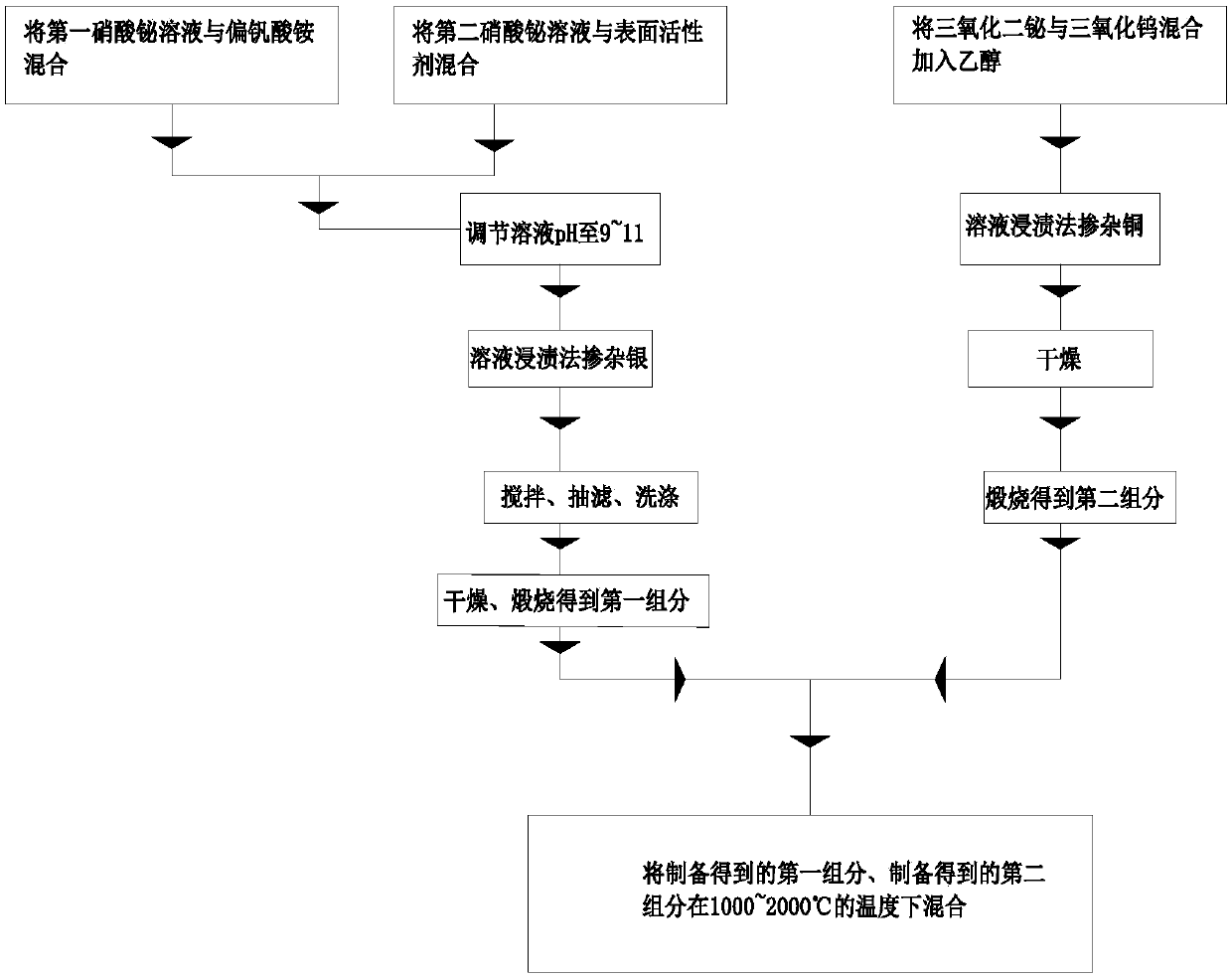

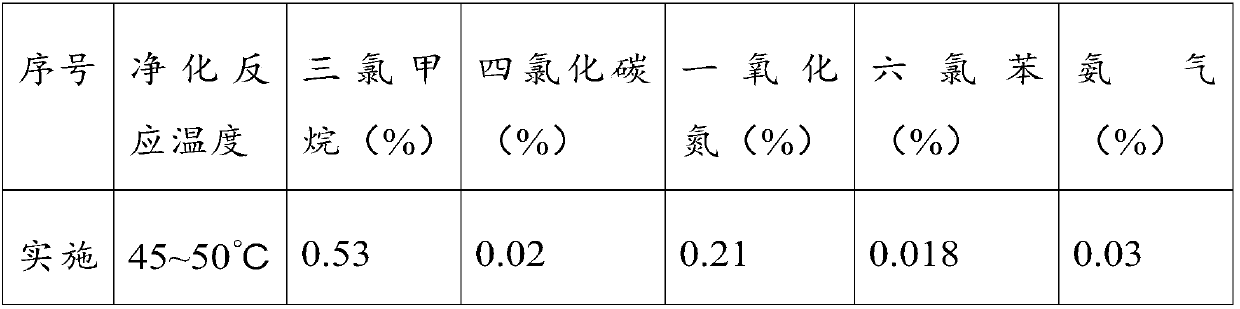

Bismuth-based semiconductor photocatalyst and preparation method thereof

ActiveCN107626298AHigh activityImprove light absorption capacityMetal/metal-oxides/metal-hydroxide catalystsAlcoholResource utilization

The invention provides a bismuth-based semiconductor photocatalyst and a preparation method thereof, and relates to the technical field of photocatalysts. The preparation method comprises the following steps: mixing a first bismuth nitrate solution and metavanadic acid to obtain a first mixed solution; mixing a second bismuth nitrate solution and surfactant to obtain a second mixed solution; mixing the first mixed solution and the second mixed solution to obtain a third mixed solution, and regulating the pH value; doping the third mixed solution with silver to obtain a fourth mixed solution, sequentially performing stirring, suction filtering, secondary washing, drying and calcining to obtain a first component; mixing bismuth trioxide and tungsten trioxide to obtain a first mixture, mixingthe first mixture with an alcohol solution to obtain a fifth mixed solution; doping the fifth mixed solution with copper, and sequentially drying and calcining to obtain a second component; and mixing the first component and the second component. The photocatalyst has a narrow band gap, good photocatalytic performance and efficient visible light resource utilization, and has a great popularization value.

Owner:YANCHENG INST OF TECH

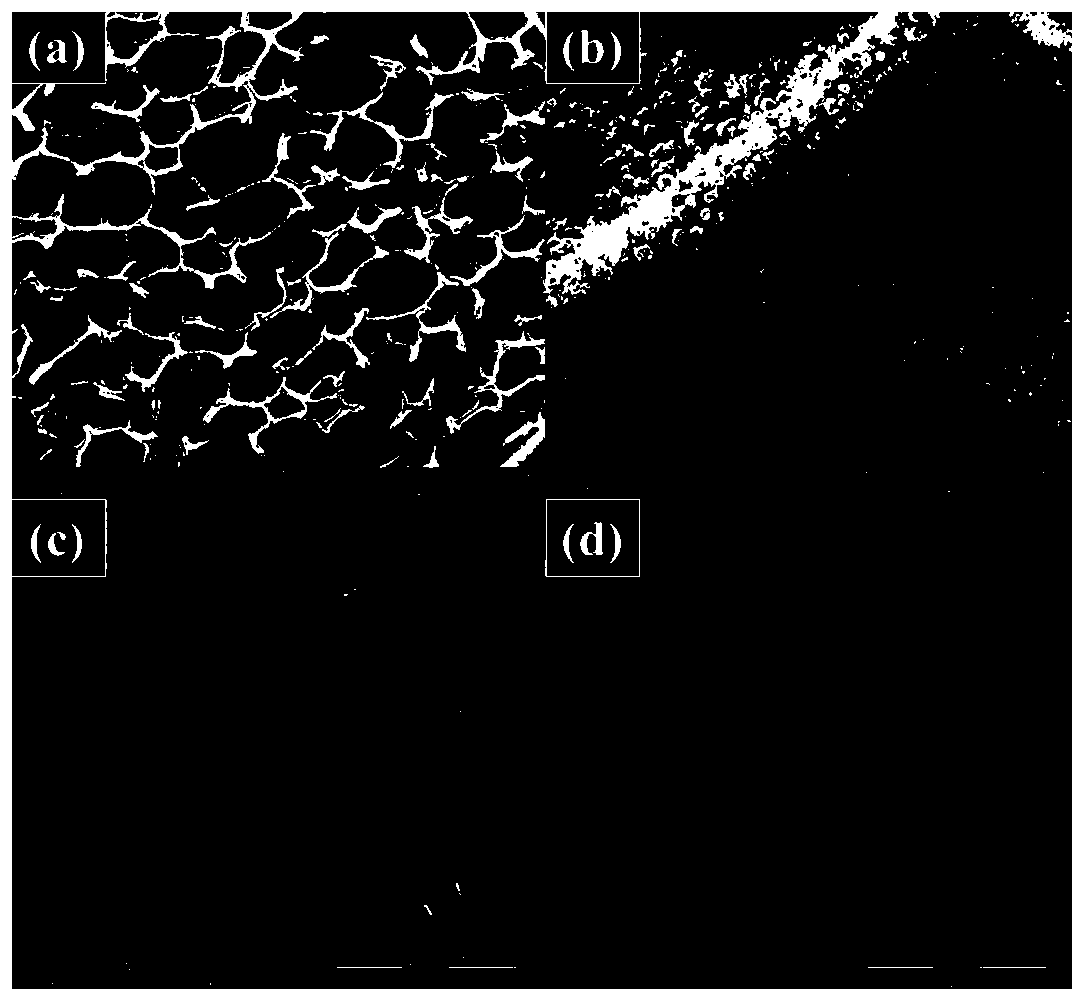

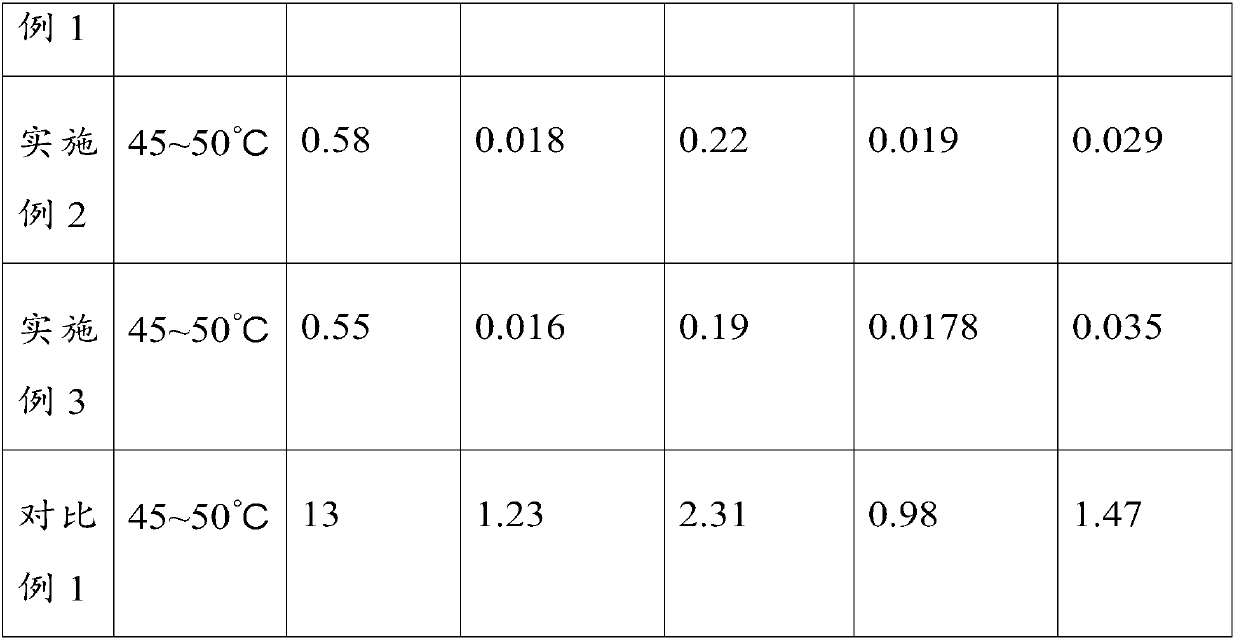

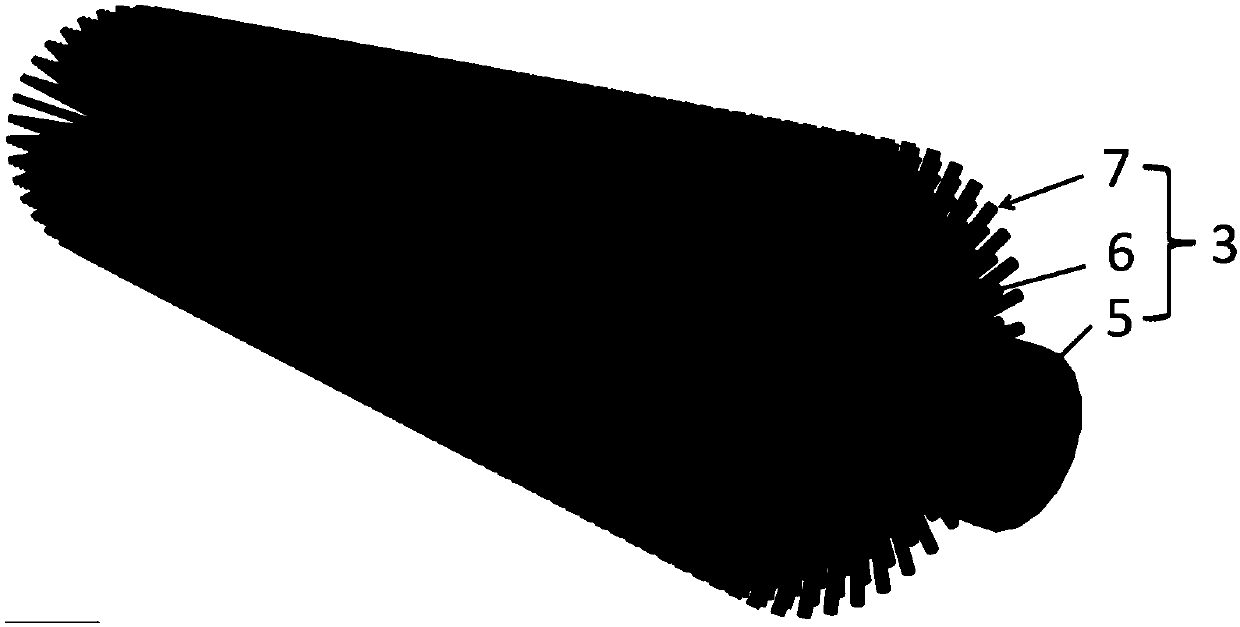

Photodetector with 3D dendritic structure and making method thereof

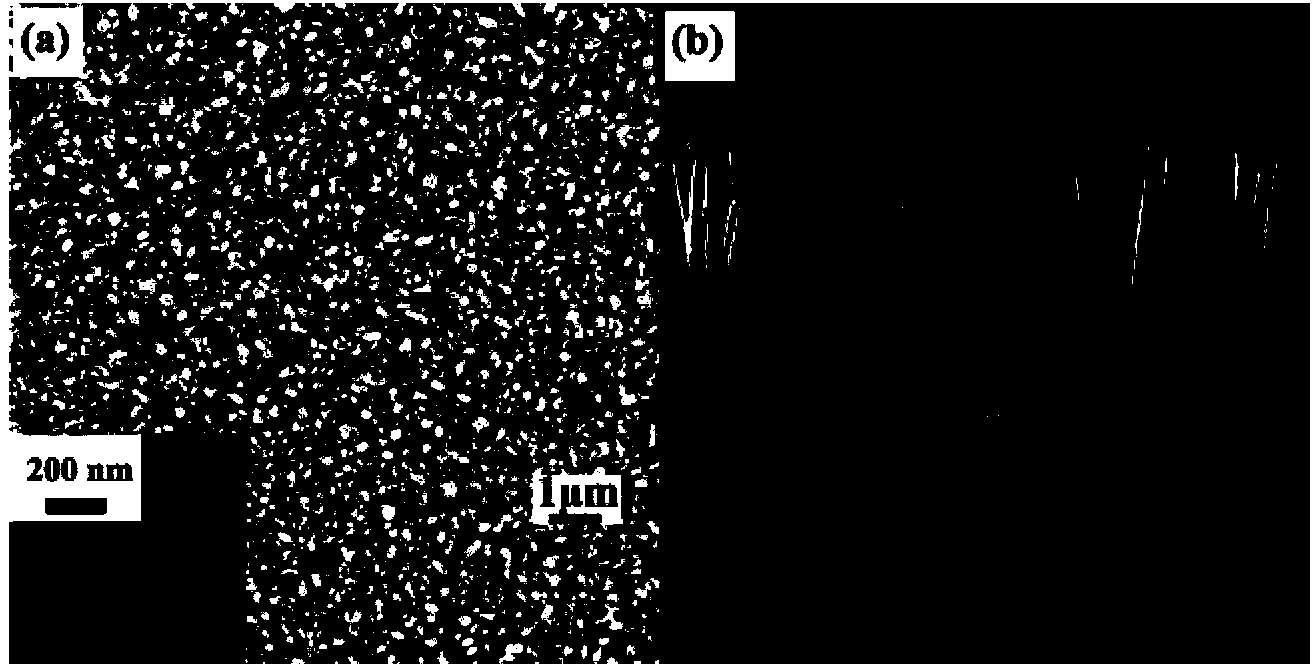

ActiveCN107591457APromote growthImprove matchFinal product manufactureSemiconductor devicesHeterojunctionPhotovoltaic detectors

The invention relates to a photodetector with a 3D dendritic structure and a making method thereof, which belong to the field of photodetectors. The photodetector comprises a Si substrate, an insulated SiO2 layer, a 3C-SiC / ZnO 3D dendritic structure heterojunction material and metal electrodes sequentially from bottom to top. Firstly, a carbothermal reduction method is used to prepare a 3C-SiC nanowire trunk; then, a deposition method is adopted to deposit a ZnO seed layer on the surface of the 3C-SiC nanowires; a hydrothermal method is then used to grow ZnO nanowire branches on the ZnO seed layer, and the 3C-SiC / ZnO 3D dendritic structure heterojunction material is formed; and finally, the single 3C-SiC / ZnO 3D dendritic structure heterojunction material is transferred to a SiO2 / Si substrate, photoetching and a stripping technology are used to plate the metal electrodes at both ends of the heterojunction material, and thus, the photodetector is obtained. The photodetector has a largerabsorption area, a larger light absorption range, a more effective photocarrier separation rate, higher photocurrent gains and a faster light response speed.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

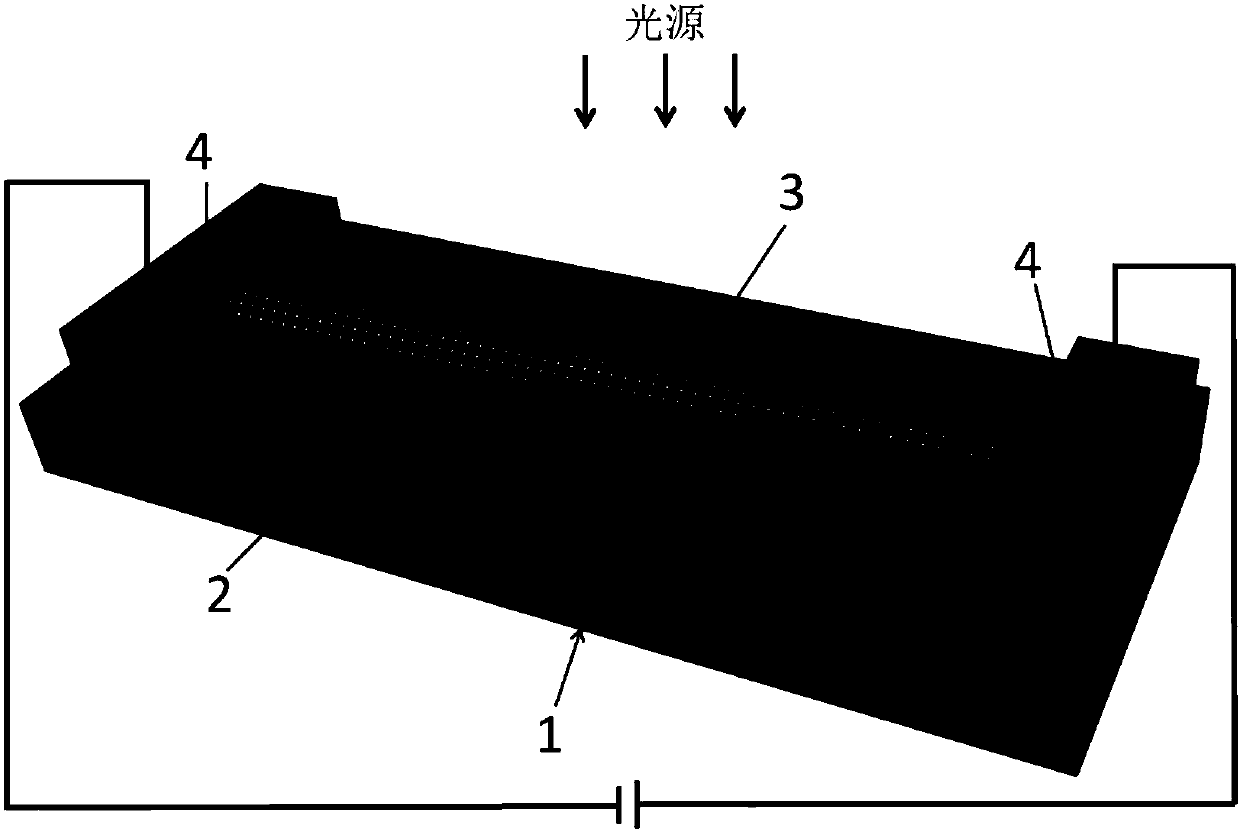

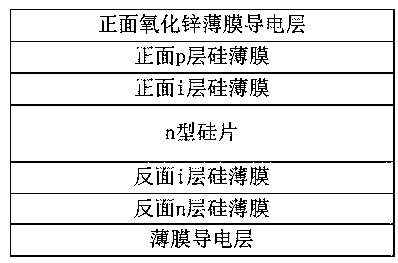

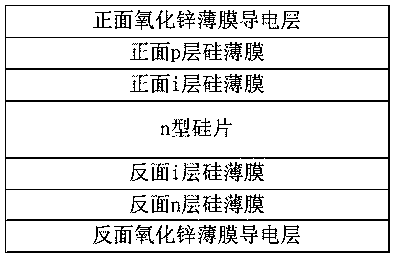

Heterojunction solar cell based on n-type silicon wafer and manufacturing method thereof

PendingCN109378347AIncrease light absorption areaSimple processFinal product manufacturePhotovoltaic energy generationHeterojunctionSolar cell

The invention discloses a heterojunction solar cell based on an n-type silicon wafer, comprising an n-type silicon wafer, a front-side i-layer silicon film, a front-side p-layer silicon film, a reverse-side i-layer silicon film, a reverse-side n-layer silicon film, a front-side film conductive layer and a reverse-side film conductive layer, wherein at least one of the front-side film conductive layer and the reverse-side film conductive layer is a zinc oxide film conductive layer; the front-side i-layer silicon film, the front-side p-layer silicon film, and the front-side film conductive layerare successively deposited on the front side of the n-type silicon wafer; and the reverse-side i-layer silicon film, the reverse-side n-layer silicon film and the reverse-side film conductive layer are successively deposited on the reverse side of the n-type silicon wafer. The manufacturing method of the heterojunction solar cell of the invention is a completely dry process, clean and hygienic, can achieve fully automated production to reduce manpower, is low in the vacuum coating process cost, and greatly improves the market application value of the heterojunction solar cell.

Owner:黄剑鸣

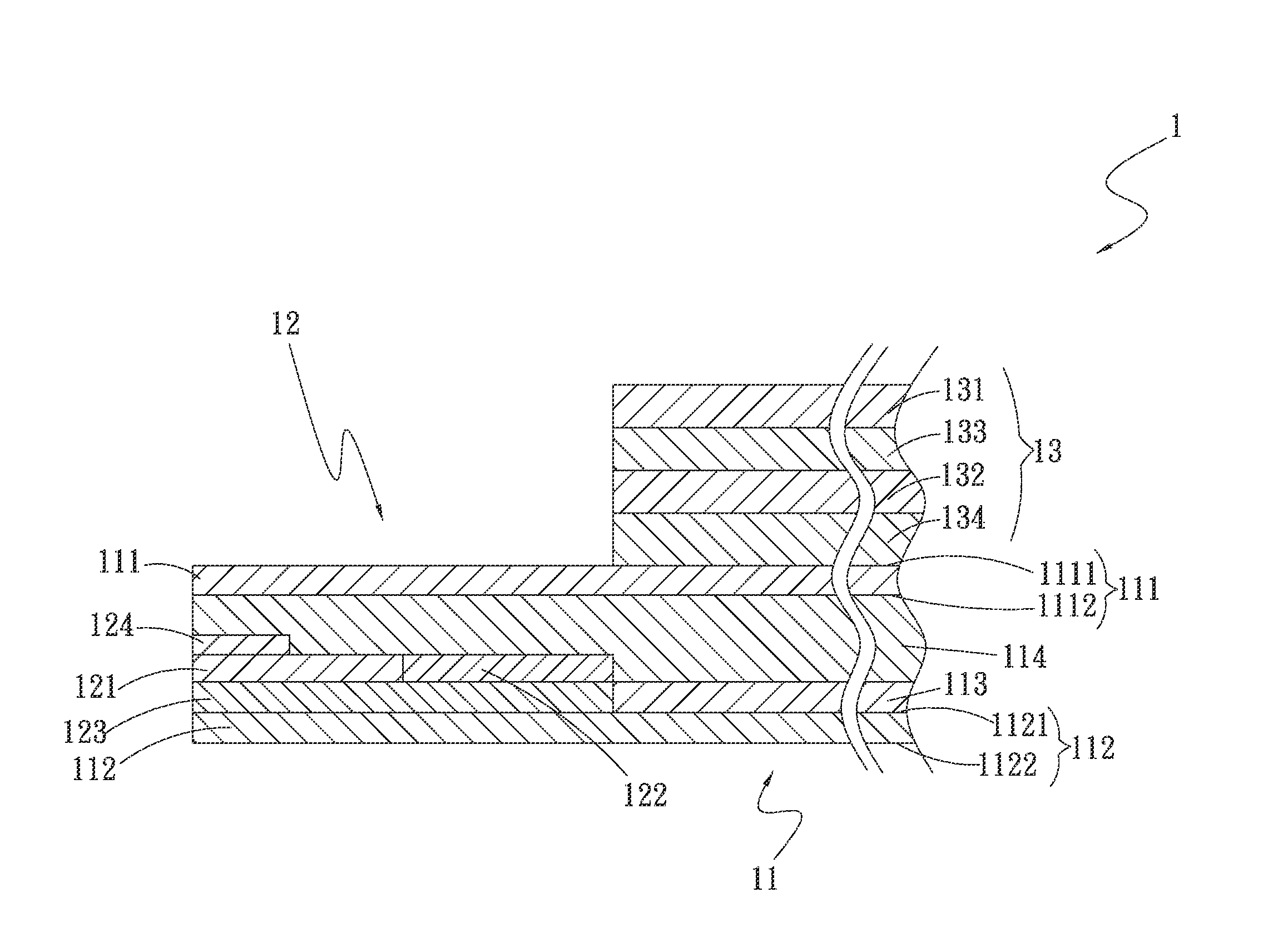

Transparent conductive oxide film based on TiN interlayer doping

ActiveCN104835554AChange optical propertiesImprove conductivityConductive layers on insulating-supportsFilm baseCharge carrier mobility

The present invention discloses a transparent conductive oxide film based on TiN interlayer doping, comprising a substrate, wherein a lower transparent conducting layer, an interlayer and an upper transparent conducting layer successively grow on the substrate from the bottom up, the lower transparent conducting layer and the upper transparent conducting layer are transparent conductive oxide layers, and the interlayer is a TiN layer. According to the transparent conductive oxide film of the present invention, a TiN film (i.e., the interlayer) is doped in a traditional TCO film, in this way, carrier concentration of the film is increased, carrier mobility is raised, and optical performance of the film of changed, so that the film can be matched with medium within a near-infrared band to generate plasma resonance, therefore, the transparent conductive oxide film can be applied to the field of optical devices within the near-infrared band, in addition, TiN is rich in source and low in price, thereby facilitating commercial promotion and application.

Owner:ZHEJIANG UNIV

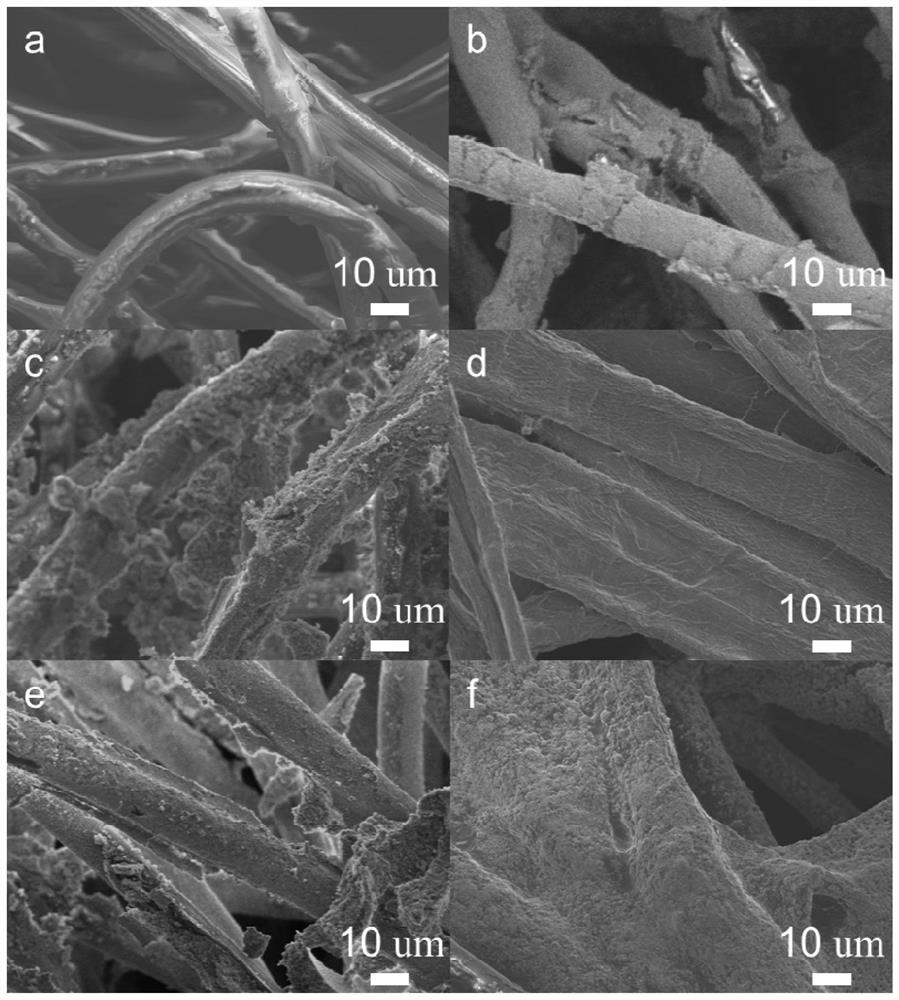

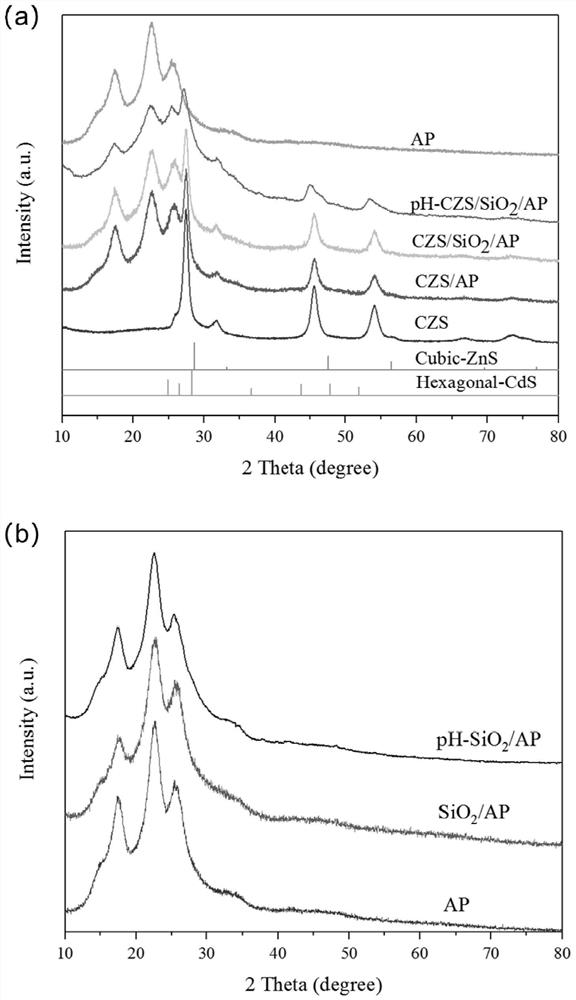

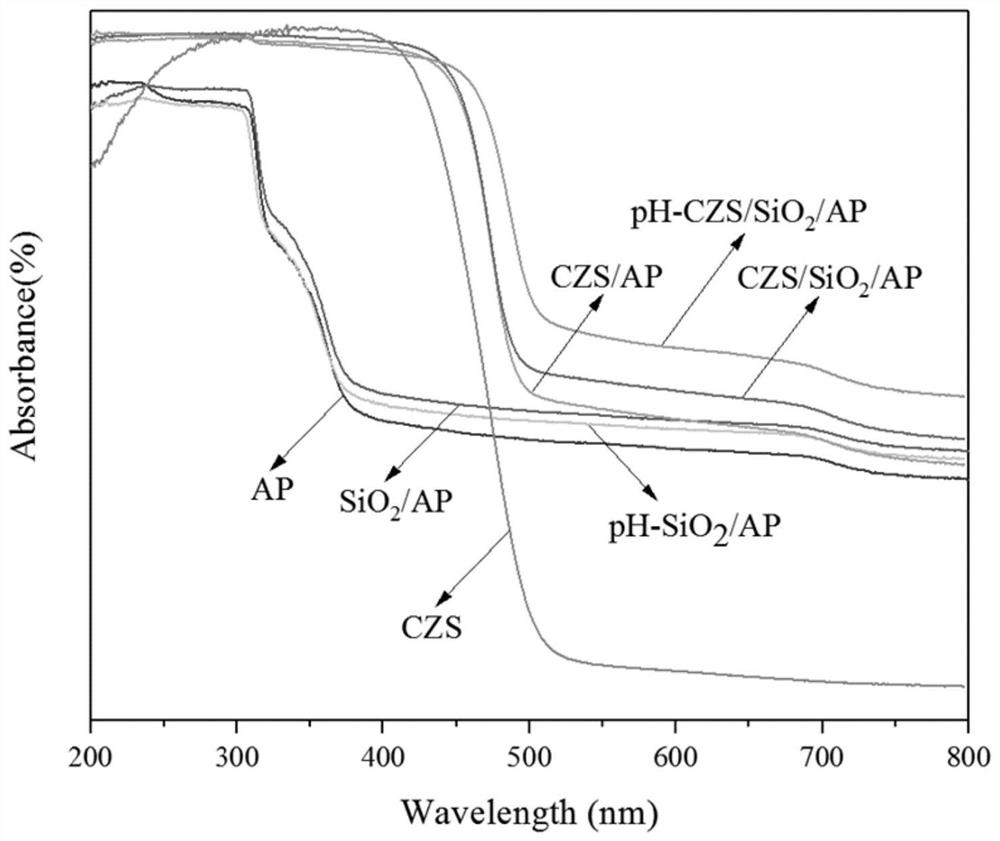

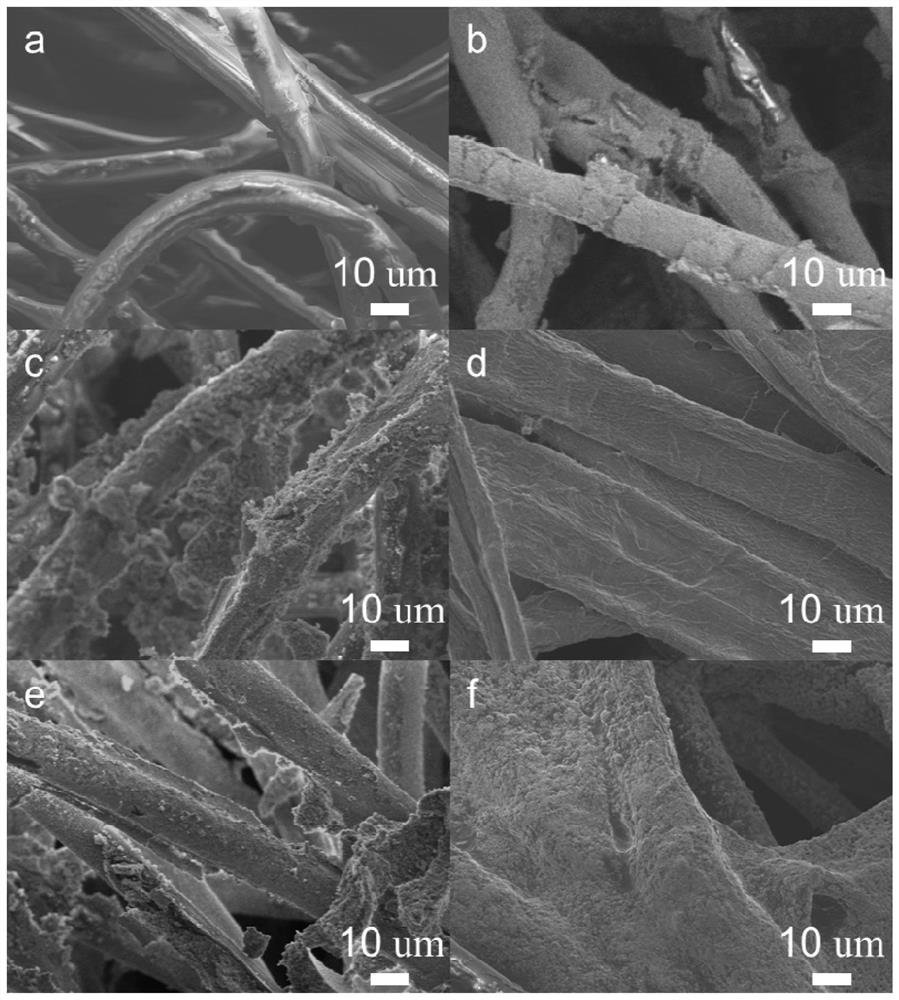

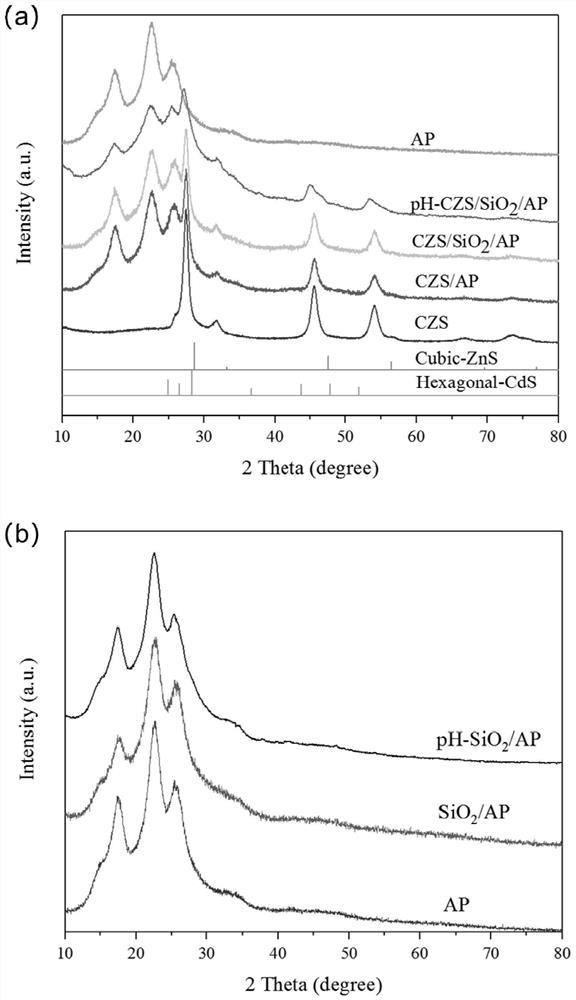

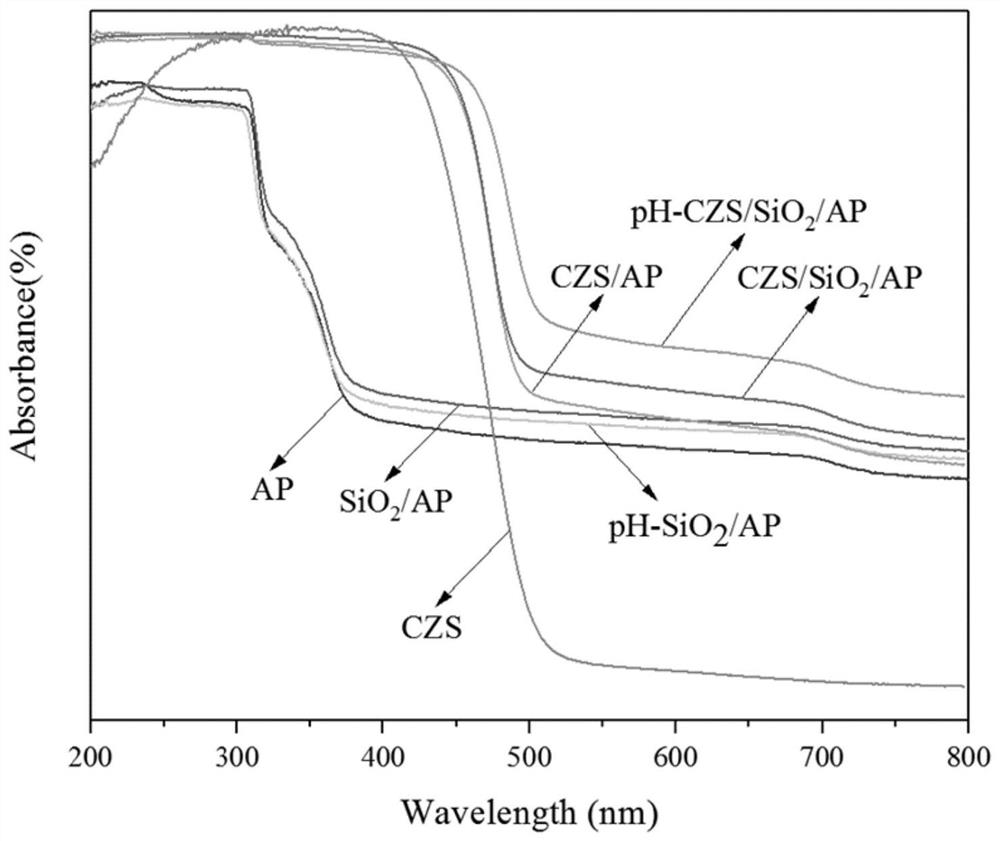

Method for immobilizing photocatalyst on flexible fiber substrate

ActiveCN112108183AGood dispersion effectGuaranteed uniformityOrganic-compounds/hydrides/coordination-complexes catalystsCatalyst activation/preparationFlexible fiberChemistry

The invention discloses a method for immobilizing a photocatalyst on a flexible fiber substrate, and belongs to a photocatalysis technology. The method comprises the steps of adding a solvent into a photocatalyst and a silicon dioxide binder to prepare a catalyst turbid liquid; coating a flexible fiber substrate with the catalyst turbid liquid, and conducting drying to obtain a photocatalyst-loaded precursor; and soaking the photocatalyst-loaded precursor in an alkaline solution, and conducting drying to obtain the target product loaded photocatalyst, wherein the loading capacity of the photocatalyst is 0.2-1.6 mg / cm<2>. Compared with other loading methods, the method has the advantages that high-temperature treatment is not needed, the silicon dioxide binder and the flexible fiber substrate are adopted, the photocatalyst can be stably loaded on the carrier only by drying, the bonding effect is good, the operation is simple and convenient, the equipment requirement is low, the cost islow, and the loaded photocatalyst can be prepared on a large scale; the photocatalytic activity is high, and the photocatalyst has better reutilization performance in an alkaline reaction solution; and the selected flexible carrier material is convenient for other treatment, stable in performance and wide in application range.

Owner:XI AN JIAOTONG UNIV

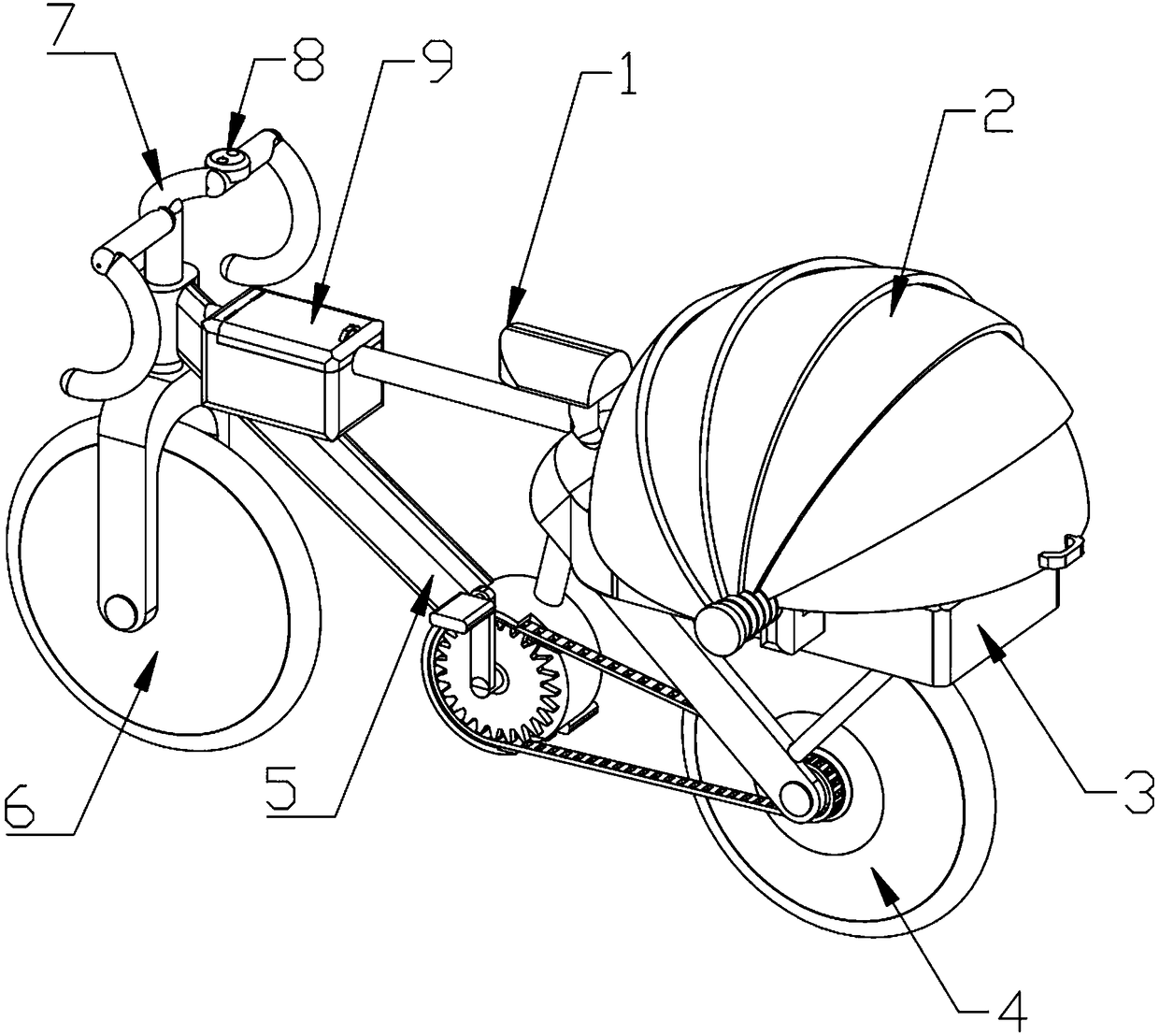

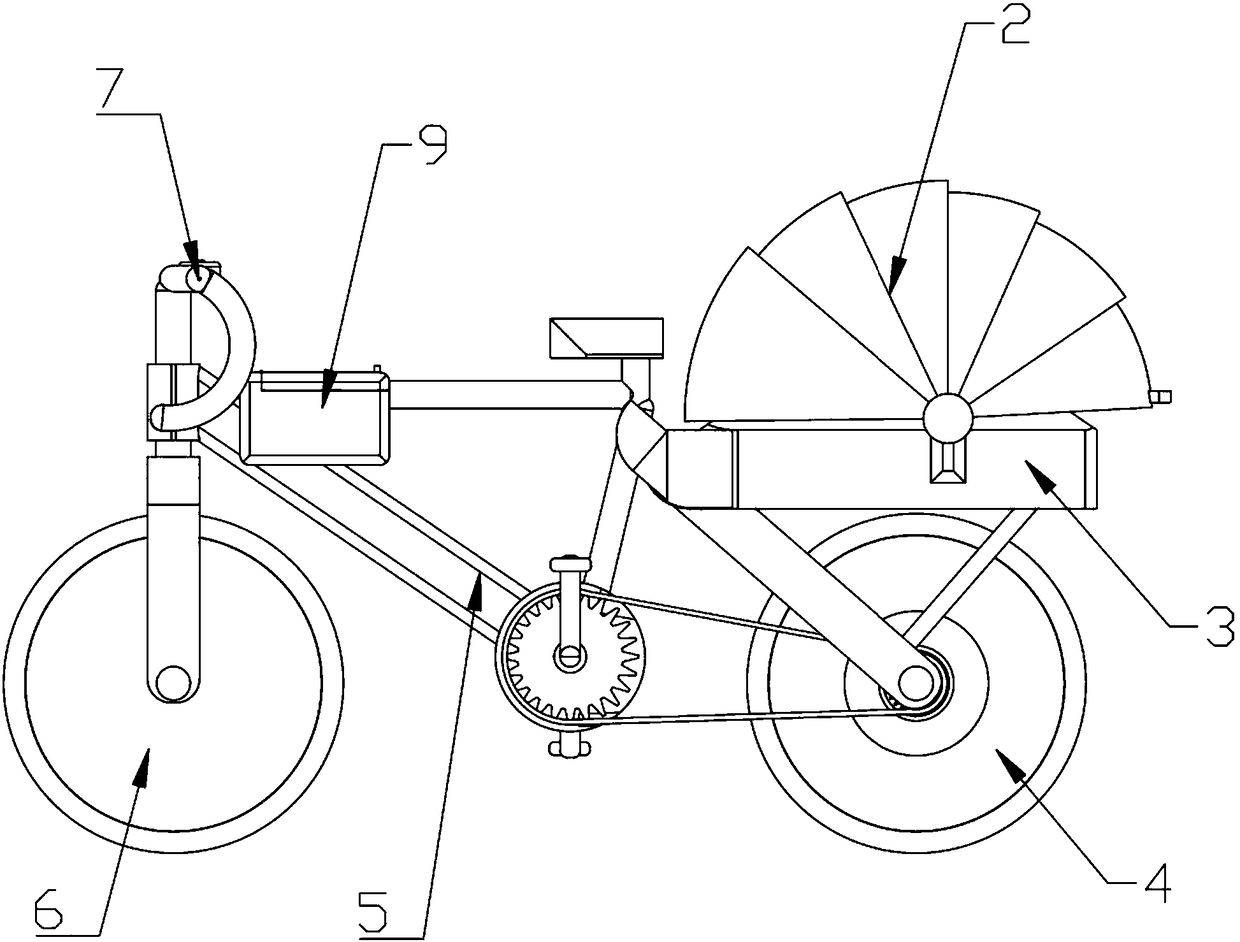

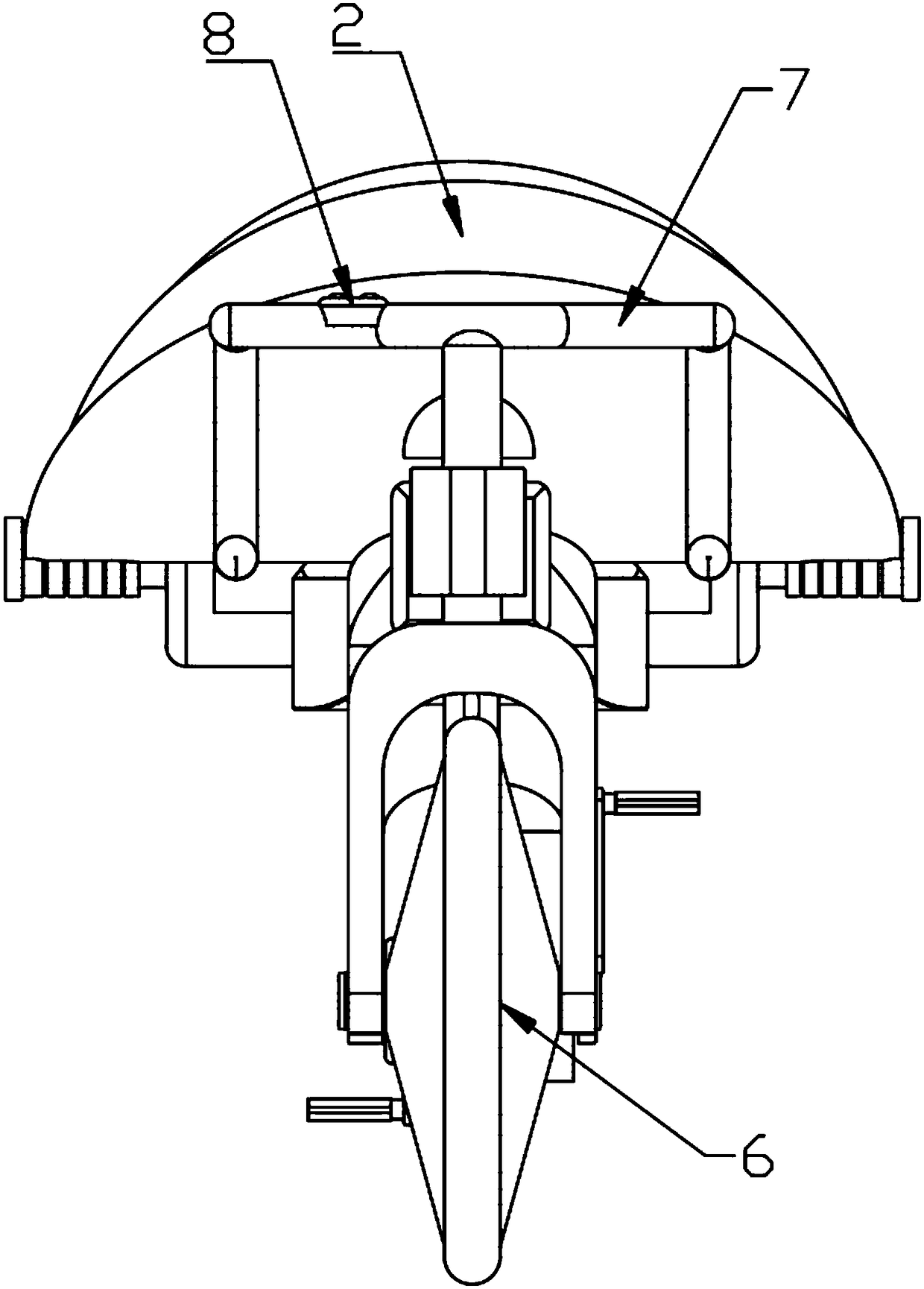

Electric power assisted bicycle with flexible solar panel power generation

InactiveCN108482565AEasy to store and placeEasy to usePV power plantsPhotovoltaic energy generationVehicle frameElectric power system

The invention provides an electric power assisted bicycle with flexible solar panel power generation. The electric power assisted bicycle comprises a solar absorber cover, storage box, control switchand USB charging hole. A bicycle frame is disposed on the bicycle body; a front wheel is fixed on the front bottom bolt of the frame, and a handlebar is welded and fixed on a top side of the frame rotating shaft on the upper side of the front wheel, and a control switch is fixed on one side of the handlebar; a storage box is welded to the front side of the beam of the frame; a rear wheel is fixedto the bottom bolt of the frame; a storage box is fixedly disposed on the upper frame of the rear wheel; the upper side of the storage box is fixedly mounted with a solar absorption cover through a fixing frame. The electric power assisted bicycle with flexible solar panel power generation is provided with a solar absorption cover designed in a rotating laminated structure of curved pieces. The rotatable switch can be stored and used, which facilitates the storage and use of the solar absorption cover, thereby effectively increasing the adjustment performance.

Owner:唐峰

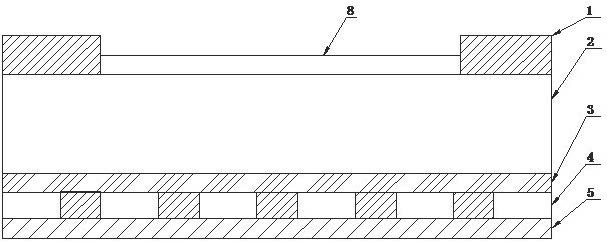

Touch device with photovolatic conversion function

InactiveUS20140126123A1Extended operating timeExtend standby timeDigital data processing detailsCurrent supply arrangementsPower flowComputer science

A touch device with photovoltaic conversion function includes a main body divided into a touch zone and a non-touch zone located immediately around the touch zone. A photovoltaic conversion layer is provided on a top of the touch zone. By providing the photovoltaic conversion layer on the top of the touch zone of the touch device, the photovoltaic conversion layer can have an increased light-absorption area to enable conversion of more light into more electric current for use by the touch device and accordingly, enable the touch device to have extended standby and operation time.

Owner:CHIH CHUNG LIN

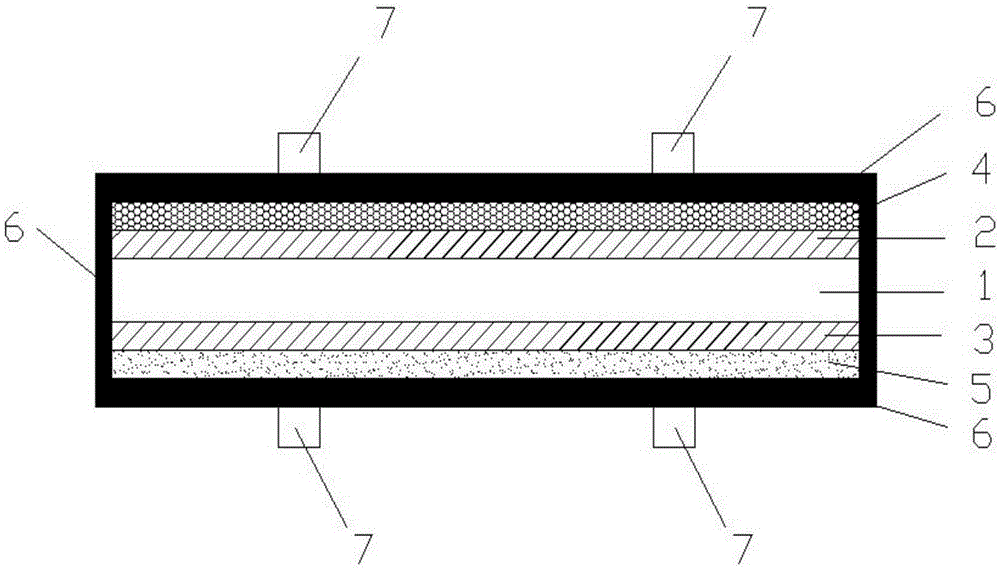

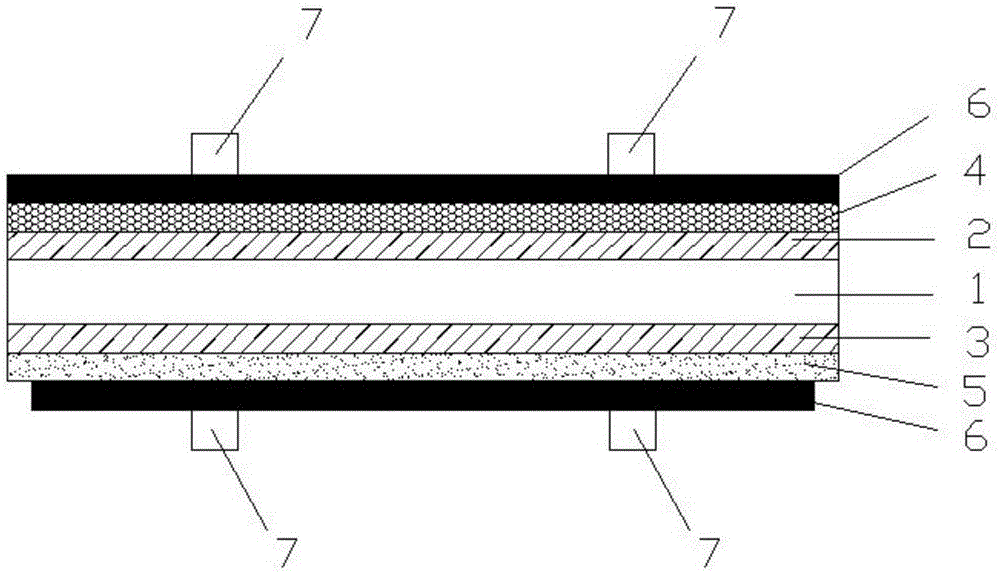

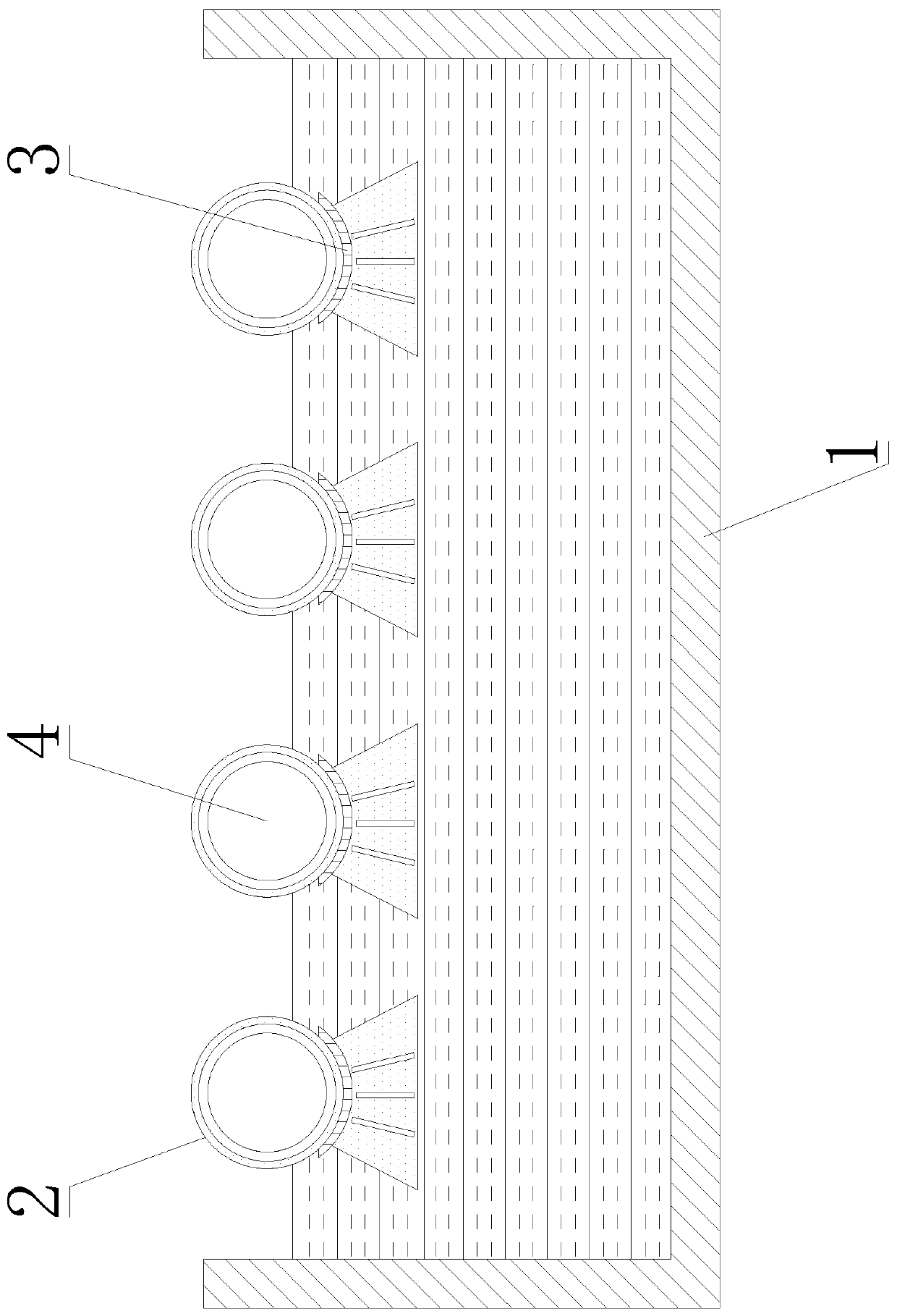

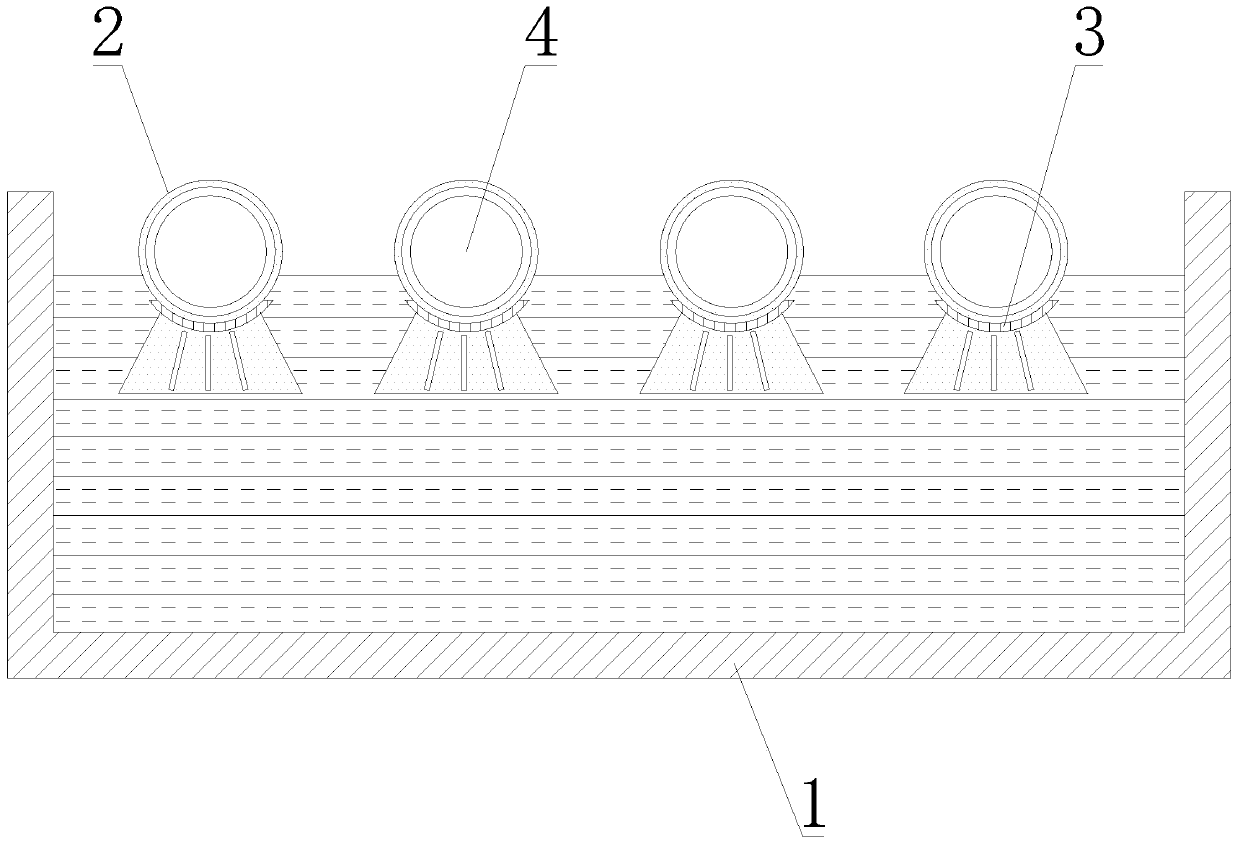

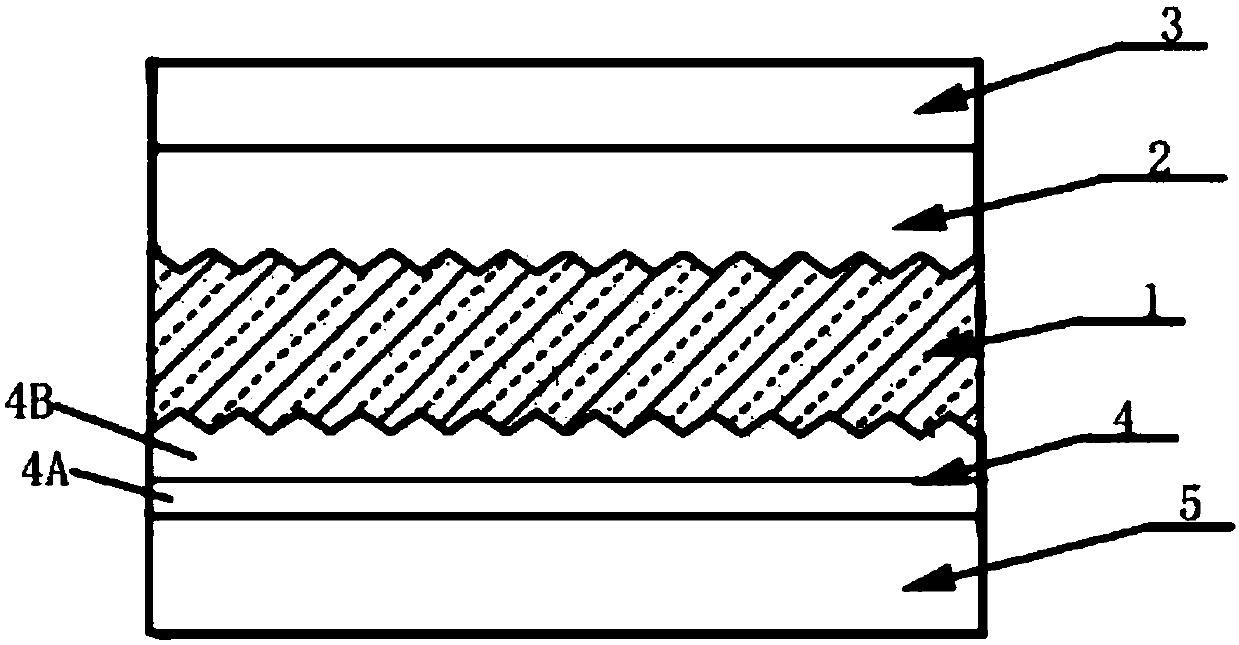

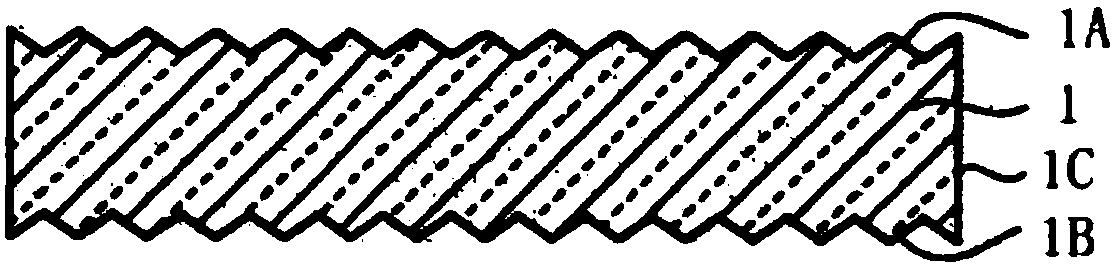

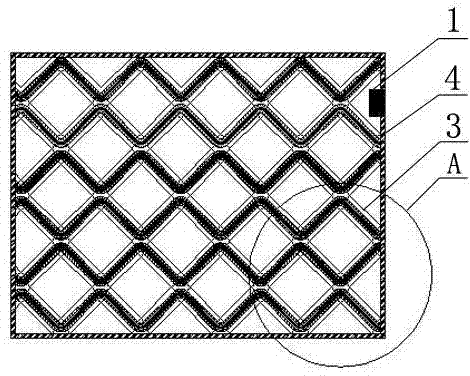

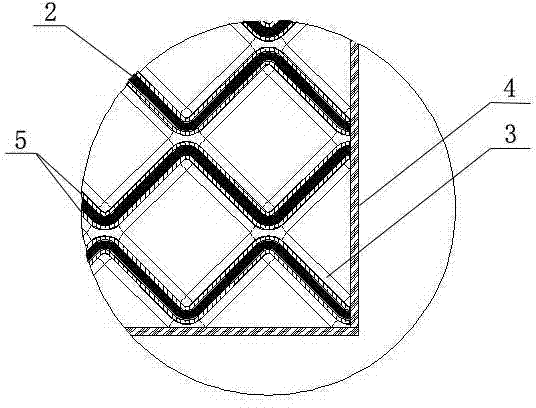

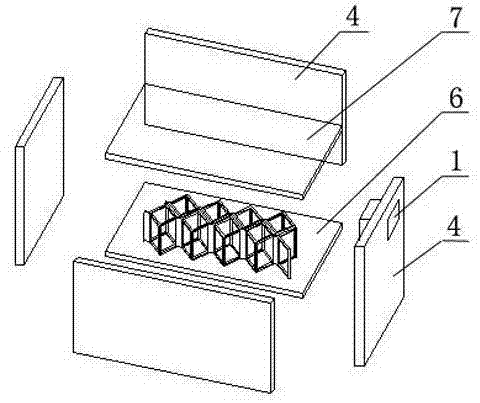

Diamond comb-shaped thin film solar panel

InactiveCN103579387AFlexibleIncrease light absorption areaPhotovoltaic supportsPhotovoltaic energy generationThree-dimensional spaceLight energy

A diamond comb-shaped thin film solar panel comprises an electric appliance function box and thin film solar cell layers. A transparent substrate is arranged in a corrugated shape on a diamond one-piece supporting frame, the two sides of the substrate are covered with the thin film solar cell layers, a bottom plate is arranged at the bottom of the supporting frame, the thin film solar cell layers are arranged on the bottom plate, a frame is arranged on the periphery of the bottom plate, and the frame is covered with a top light-transmitting plate. In this way, the photovoltaic effect produced by the situation that the thin film solar cell layers absorb the top light photoemission is increased, and the diamond comb-shaped three-dimensional light absorption area of the corrugated-shaped substrate is increased, and light absorption conversion is larger than 39%. According to the diamond comb-shaped thin film solar panel, by means the process structure of three-dimensional space, the light absorption area of the thin-film solar cell is effectively increased, and the light-energy conversion efficiency is improved. The diamond comb-shaped thin film solar panel is convenient to assemble, maintain and replace in an integral mode and convenient to use due to the fact that local replacement further can be achieved, thereby having high commercial popularization value.

Owner:PINGDINGSHAN ZHONGJIA ENERGY TECH

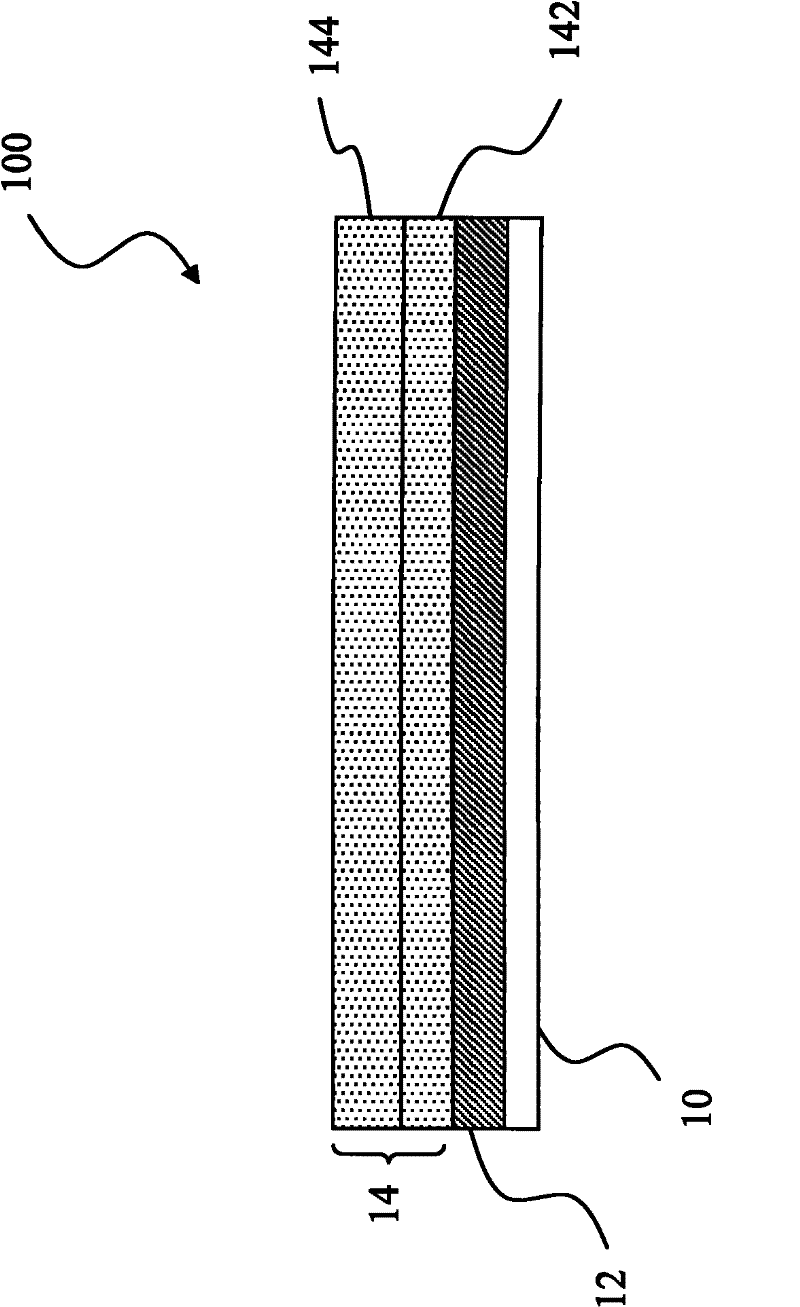

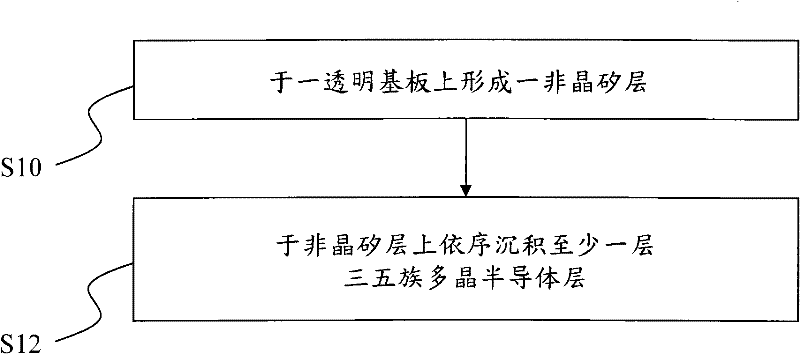

Solar battery structure for group II to V polycrystal semiconductors and manufacture method thereof

InactiveCN102479848AIncrease the areaIncrease light absorption areaFinal product manufacturePhotovoltaic energy generationAmorphous siliconSolar battery

The invention provides a solar battery structure for group II to V polycrystal semiconductors and a manufacture method thereof. The solar battery structure for the group II to V polycrystal semiconductors comprises a transparent base plate, an amorphous silicon layer and at least one group II to V polycrystal semiconductor layer, wherein the amorphous silicon layer is formed on the transparent base plate by using a plasma assisted chemical vapor deposition method, and the group II to V polycrystal semiconductor layer is sequentially formed on the amorphous silicon layer by a metal organic chemical vapor deposition method. Because the transparent base plate is adopted for replacing the traditional group II to V base plates, the solar battery structure and the manufacture method have the advantages that the cost can be greatly reduced, the area of the solar battery is increased, further, the light absorption area is increased, and the conversion efficiency is improved.

Owner:JIFU NEW ENERGY TECH SHANGHAI

A photocatalyst immobilization method on a flexible fiber substrate

ActiveCN112108183BGuaranteed uniformityIncrease surface areaOrganic-compounds/hydrides/coordination-complexes catalystsCatalyst activation/preparationPtru catalystPhysical chemistry

Owner:XI AN JIAOTONG UNIV

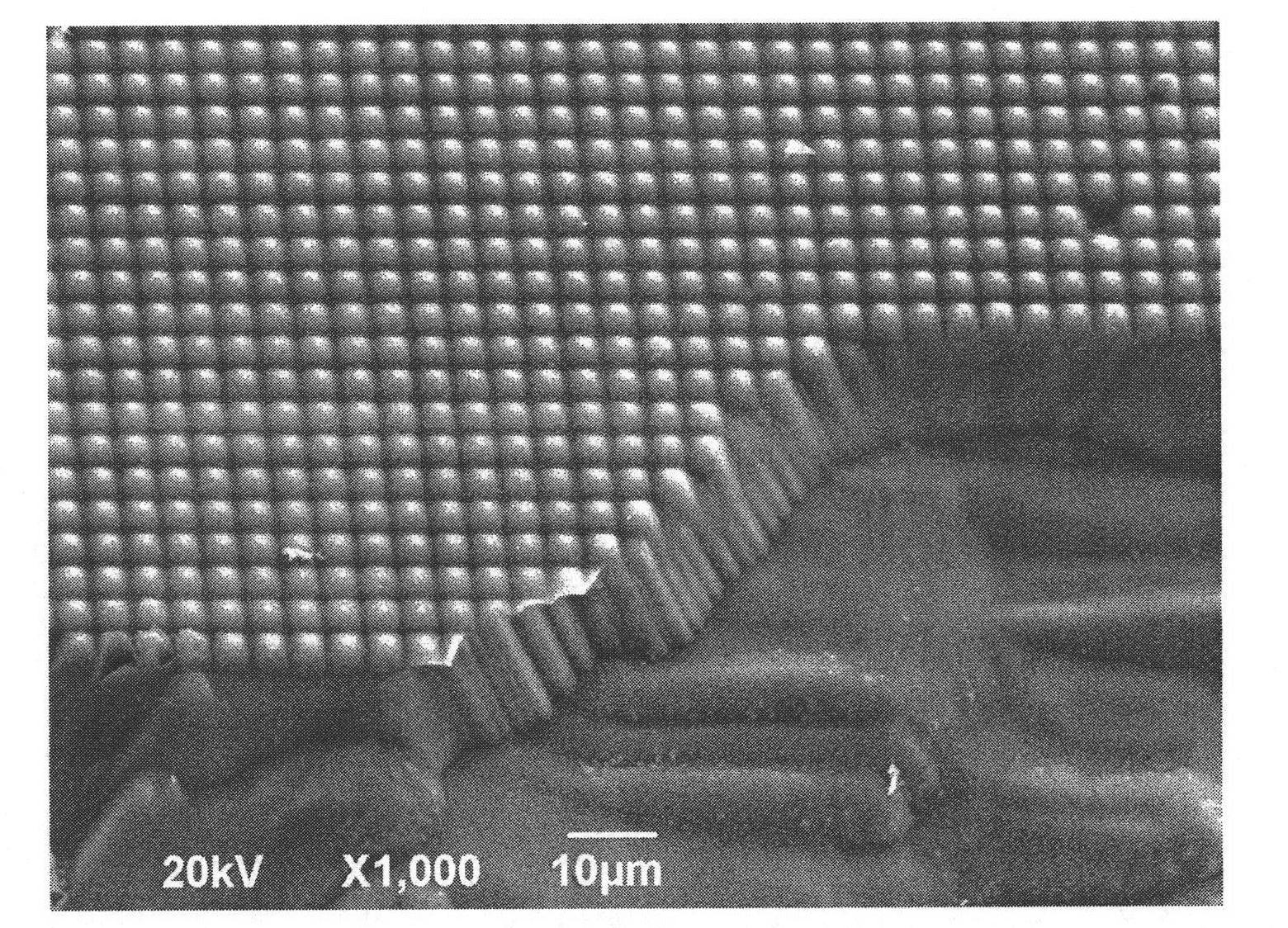

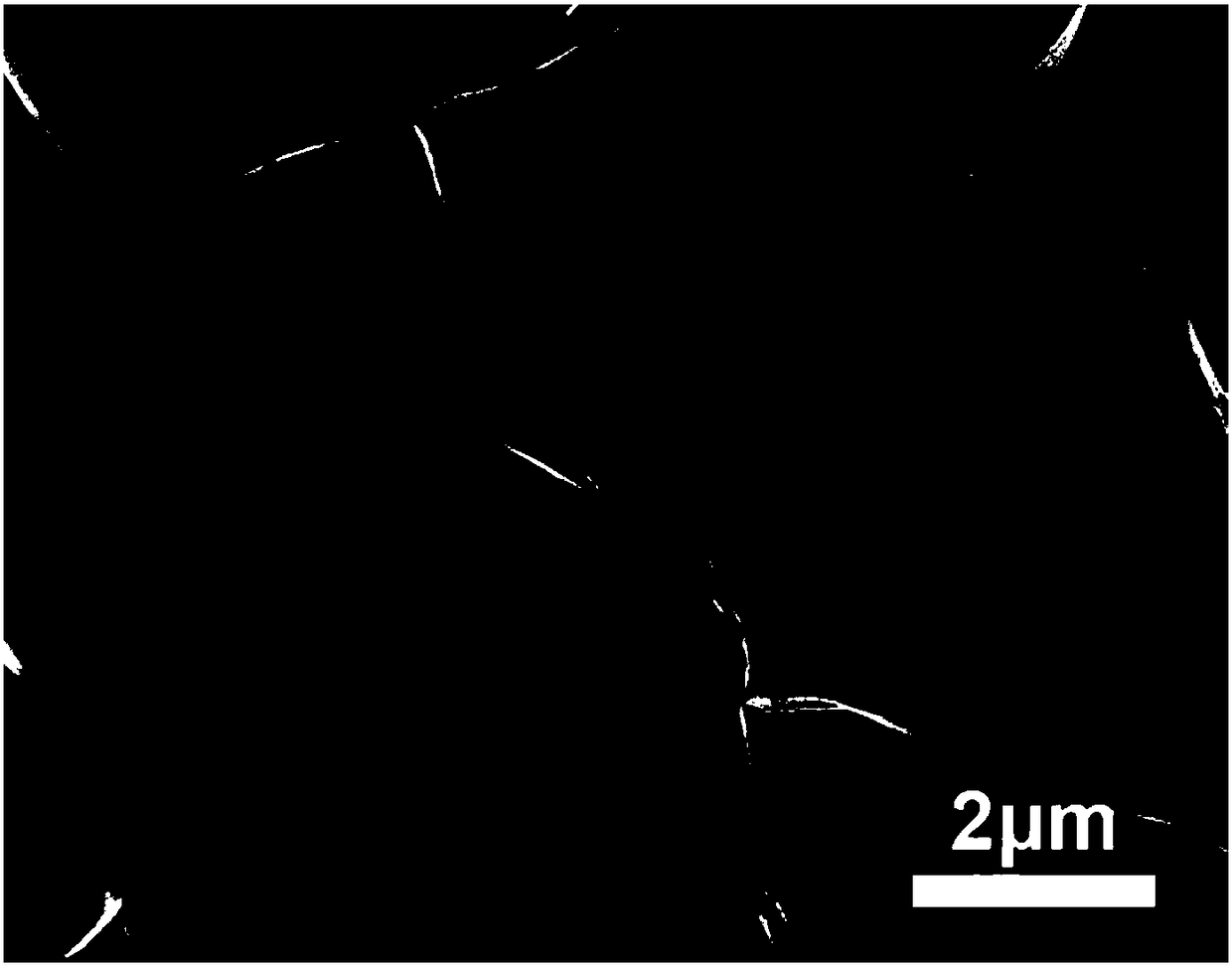

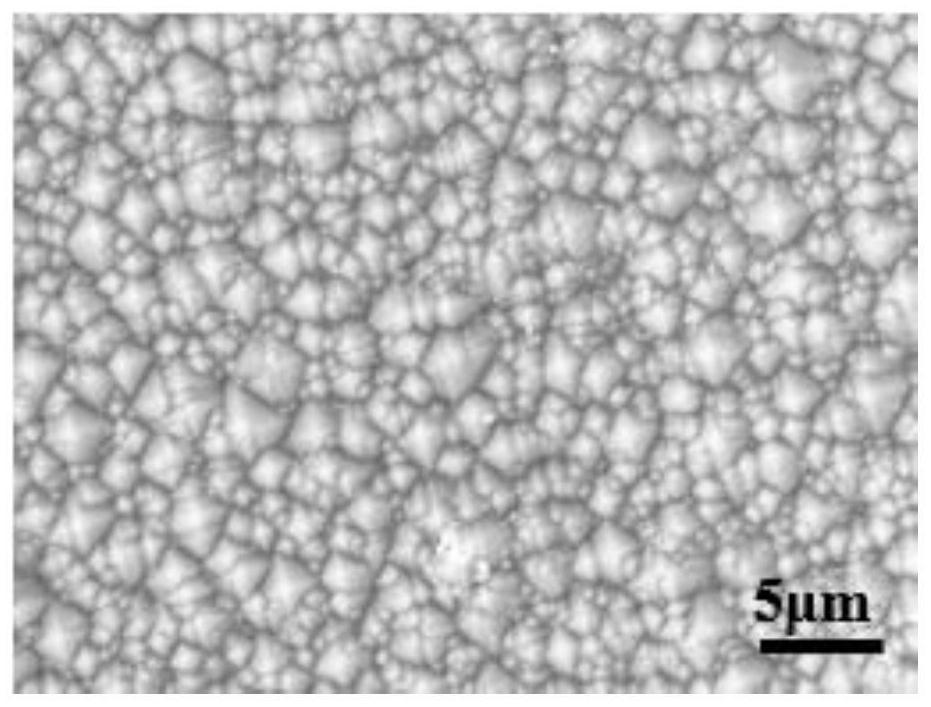

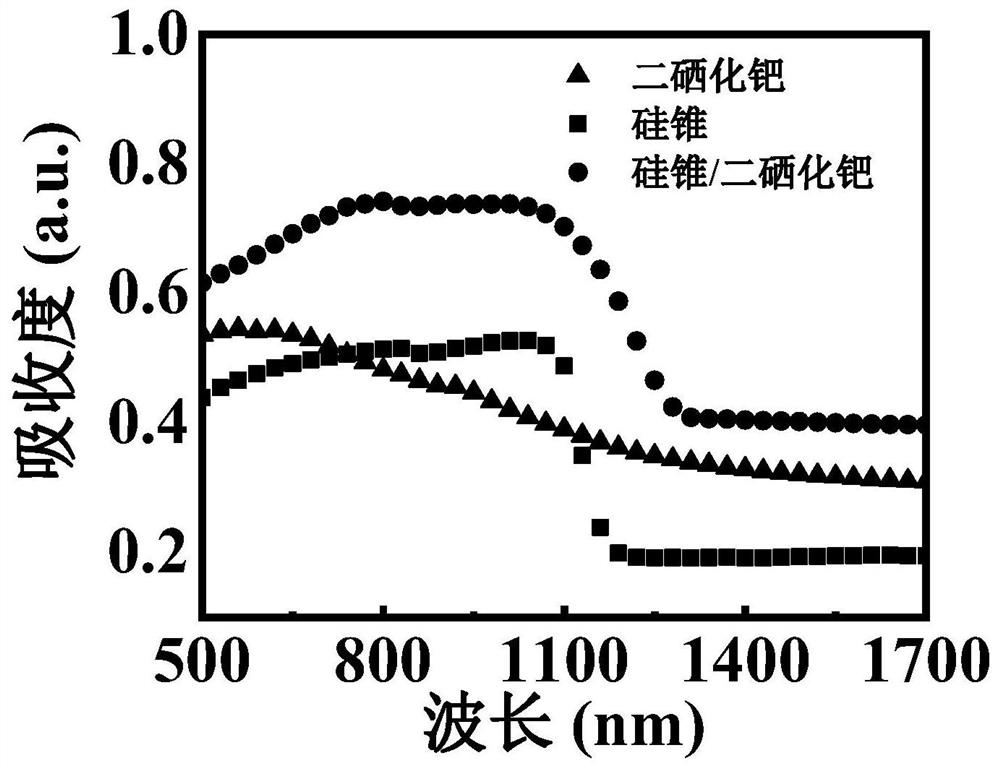

Broad-band high-performance photodetector based on palladium selenide thin film/silicon cone wrapping structure heterojunction and its manufacturing method

ActiveCN110190150BEasy to makeImprove performanceFinal product manufactureNanoopticsHeterojunctionPhotovoltaic detectors

The invention discloses a wide-band high-performance photodetector based on a palladium selenide thin film / silicon cone wrapped structure heterojunction and a preparation method thereof. The silicon cone is firstly etched on an n-type lightly doped silicon wafer with a silicon oxide layer. structure, and then wrap PdSe outside the silicon cone structure 2 film, so that the two form a heterojunction. The photoelectric detector of the invention has simple device preparation process, stable and good performance, and opens up new prospects for the application of transition group metal selenide materials in photoelectric detectors.

Owner:HEFEI UNIV OF TECH

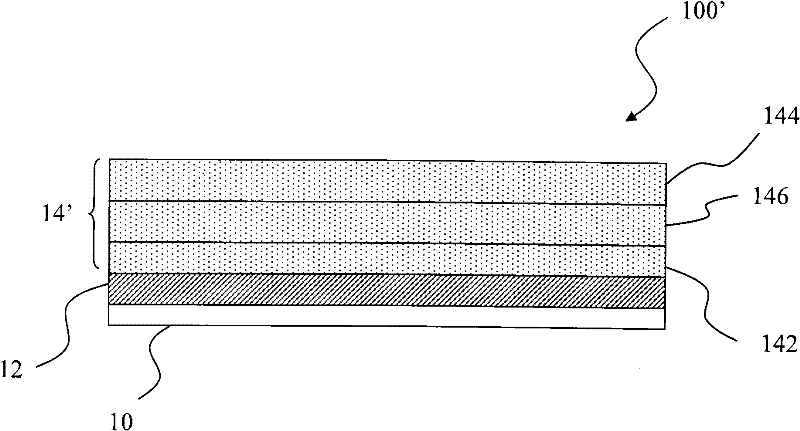

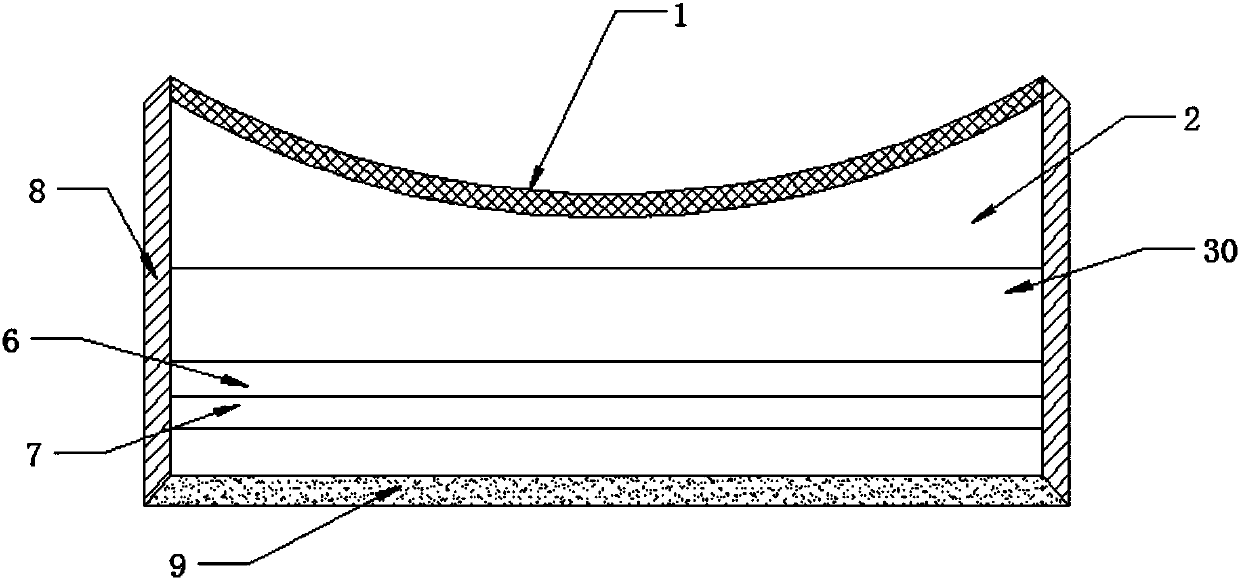

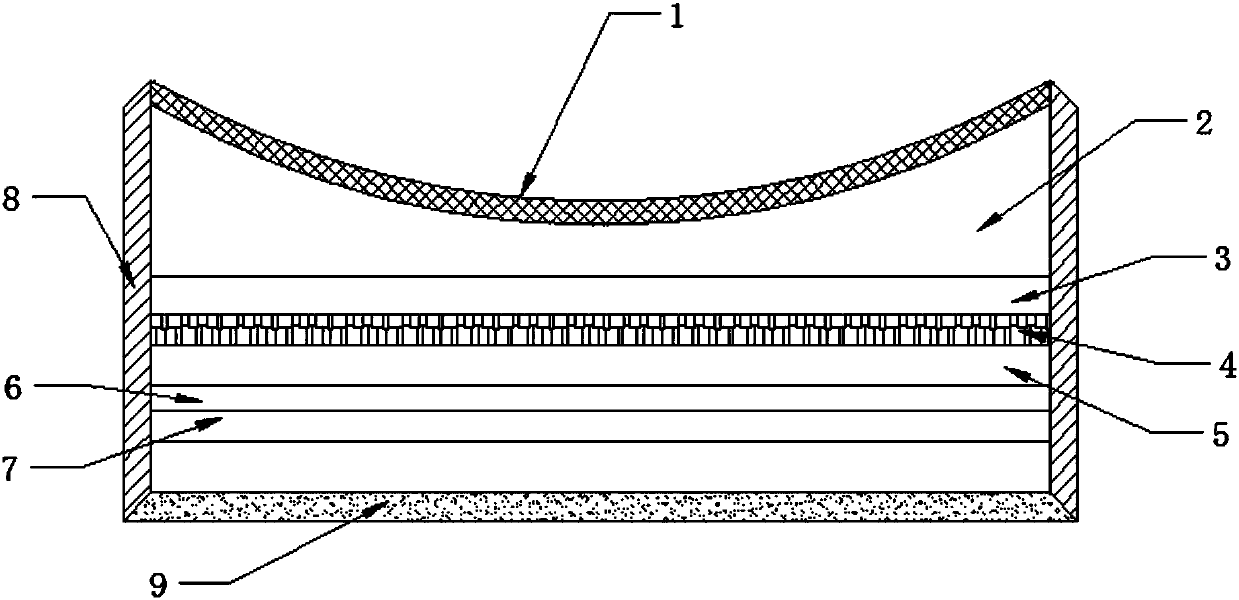

A kind of solar cell structure of Ⅲ-ⅴ semiconductor and its manufacturing method

InactiveCN106653922BEffective absorptionExtended service lifeFinal product manufacturePhotovoltaic energy generationLight energyAmorphous silicon

The invention discloses an III-V family semiconductor solar energy cell structure and manufacturing method thereof, comprising a protection housing and the following layers arranged inside the protection housing in succession from the bottom to the top: a transparent substrate, an amorphous silicon layer, an III-V family polycrystalline semiconductor layer, a transparent light transmission layer and a light absorption layer. The bottom end of the protection layer is flexibly provided with a protection bottom plate. The light absorption layer is designed into a recessed arc shape and agrees with the concave groove on the transparent light transmission layer; the surface and the inner part of the transparent light transmission layer are provided with a plurality of micro-holes so that incoming light rays could be guided into the III-V family polycrystalline semiconductor layer horizontally. In the invention, an arc shaped light absorption layer, a transparent light transmission layer and a transparent substrate are used in the structure, which not only extends the service life of the structure and reduces the overall cost, but also increases the light absorption size, effectively absorbs light energy and raises the conversion efficiency of the solar energy cell to the light.

Owner:YANBIAN UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com